Expanded Polystyrene (EPS) foam is one of the most popular insulating materials, prized for its light weight and thermal efficiency. However, a crucial question for builders and homeowners is its performance when exposed to moisture. Does this bead-based foam absorb water, and if so, how does that affect its insulating R-value and longevity in damp environments?

The misconception that EPS readily soaks up water can lead to poor material choices in construction. Understanding the cellular structure of EPS is key to resolving this myth. We’ll explore the science behind EPS’s excellent moisture resistance and detail how factors like density and long-term exposure truly impact its performance.

What is EPS Foam?

EPS foam, also known as expanded polystyrene foam, is a lightweight, rigid, and versatile material widely used in various industries for insulation, packaging, and construction purposes.

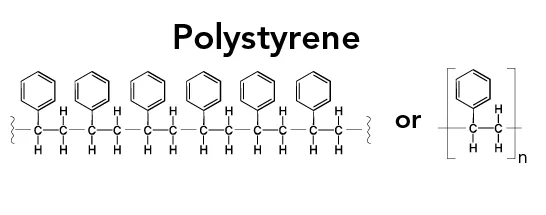

It is derived from polystyrene, a thermoplastic polymer made from the monomer styrene.

The manufacturing process of EPS foam involves expanding polystyrene beads using steam and then molding them into desired shapes. During expansion, the polystyrene beads are subjected to heat, causing them to soften and expand as the trapped air within the beads expands. This process results in a cellular structure with closed, interconnected cells, giving EPS foam its characteristic lightweight and insulating properties.

EPS Structure

The fundamental properties of Expanded Polystyrene (EPS) are directly derived from its microscopic structure, which is the result of a precise manufacturing process involving steam and pressure. The resulting foam is over 95% trapped air, giving it its defining characteristics of being extremely lightweight and highly insulative.

This rigid foam’s unique cellular formation and the way its component parts interact determine its strength, thermal performance, and moisture resistance in all final applications. Understanding this physical architecture is essential for specifying the right grade of foam for any structural or packaging need.

Manufacturing by Expansion: The process begins with solid polystyrene beads impregnated with a blowing agent (typically pentane). Steam heat causes the agent to vaporize and expand the beads up to 50 times their original size. This controlled expansion and fusion create the rigid, stable block that is then cut into various products.

Closed-Cell Beads: Each individual bead of EPS is a polymeric foam formed from tiny, enclosed cells that trap air. This closed-cell geometry is what provides the core of the foam’s thermal resistance (R-value), as trapped, still air is a very poor conductor of heat, greatly minimizing thermal transfer through the insulation material.

Bead Fusion and Interstitial Voids: In the molding process, pre-expanded beads are subjected to steam and pressure, causing their softened surfaces to fuse together. While the interior of each bead is closed-cell, tiny channels or voids exist in the irregular spaces where the beads tangentially meet, allowing for some slight moisture ingress over time.

Trapped Air Composition: The final EPS structure is composed of approximately 98% air by volume and only 2% polystyrene material. This high air content is the primary reason for the material’s remarkably low density and light weight, making it exceptionally easy to handle and install in large blocks or sheets for construction.

Does EPS Foam Absorb Water?

Yes, EPS foam can absorb water.

Expanded Polystyrene (EPS) foam is highly water-resistant but not entirely waterproof. Its structure is primarily a matrix of closed cells that inherently repel moisture. However, the manufacturing process leaves microscopic voids between the fused beads that allow for limited water absorption, especially over long periods or through capillary action.

This is a critical distinction, as the amount and pathway of water ingress directly impacts the foam’s insulating performance, or R-value, over time in various real-world applications.

Density and Resistance: The foam’s density significantly affects its water resistance. Higher-density EPS foam has beads that are more tightly fused with fewer and smaller voids, which naturally restricts the pathways for liquid water to enter the material, improving performance in moist environments.

Hydrophobic Polymer Base: The base material, polystyrene, is naturally hydrophobic, meaning it repels water. This core property ensures the individual closed cells within the foam beads do not readily absorb liquid water, minimizing moisture accumulation within the material’s main structure.

Interstitial Channels: The EPS manufacturing process fuses small beads together, creating tiny channels in the voids between them. These voids are where water primarily enters the foam, typically through capillary action, allowing a small but measurable amount of water absorption, often less than 4% by volume.

Impact on R-Value: When water does fill the interstitial voids, it creates a conductive path that reduces the material’s R-value, as water conducts heat much better than air. However, EPS also has a higher permeability than XPS, allowing it to dry out more quickly and retain more of its R-value long-term.

What Happens if EPS Gets Wet?

When Expanded Polystyrene (EPS) foam gets wet, the primary consequence is a reduction in its insulating efficiency due to water filling the small voids between the fused beads. While EPS is highly water-resistant and the polystyrene material itself repels water, prolonged or constant exposure allows a small amount of water to seep in, which can compromise its thermal performance. Fortunately, EPS also possesses a high drying potential, allowing it to shed absorbed moisture more readily over time.

Loss of Thermal Resistance (R-Value)

Water is an excellent conductor of heat, far more efficient than the trapped air within the foam’s cells. When water infiltrates the foam’s structure through the interstitial gaps, it bypasses the insulation, significantly decreasing its R-value and reducing the material’s ability to resist heat flow.

Reduced Long-Term Performance

The water absorption, though typically low (often under 4% by volume), is a long-term threat to efficiency. However, a key advantage of EPS is its high vapor permeability, meaning the absorbed moisture can escape and the foam can dry out, allowing it to retain a higher percentage of its R-value over decades in below-grade use.

Risk of Freeze-Thaw Damage

In cold climates, if the absorbed water in the foam’s voids freezes, the expansion can put stress on the material’s structure. Repeated freeze-thaw cycles can theoretically break the bonds between the foam beads, potentially leading to minor structural degradation and decreased physical integrity over time.

Potential for Mold and Pests

While the polystyrene material itself doesn’t support mold growth, the presence of trapped moisture can create a damp environment adjacent to other materials, like wood, which can promote mold or mildew growth. Additionally, wet insulation may attract certain pests like carpenter ants seeking water.

Conclusion

The cellular structure of EPS provides excellent resistance to water absorption, especially when compared to other insulation materials. While EPS is not completely impervious, its closed-cell nature prevents significant capillary action, ensuring that minor exposure or even prolonged submersion does not severely compromise its thermal performance over time. This makes it a reliable choice for below-grade applications.

To ensure you harness the maximum durability and moisture resilience of EPS foam, always specify and install high-density, professional-grade products that are correctly protected by external barriers. This diligence preserves the material’s structural integrity and critical R-value for the entire lifespan of your building or packaging application.

For all your construction and packaging needs, rely on our premium, quality-tested Expanded Polystyrene products. You can get wholesale EPS products from our Epsole and secure a material that delivers on its promise of moisture resistance, thermal efficiency, and long-term performance. Contact us today for bulk orders!