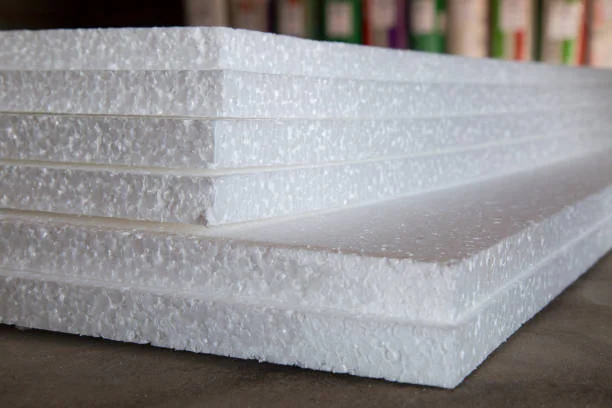

When it comes to working with thick Styrofoam, finding the most effective cutting method is crucial to achieving clean and precise results. In this blog, we’ll explore the best ways to cut through this material and get the job done right.

Cut Thick Styrofoam Tools

When it comes to cutting thick Styrofoam, there are several tools that can get the job done effectively.

One of the commonly used tools is a hot wire cutter. This device consists of a heated wire that can easily slice through the Styrofoam with precision. The heat melts the Styrofoam as it cuts, resulting in a clean and smooth edge. Another useful tool is a serrated knife or saw specifically designed for cutting foam materials. The serrations help grip the Styrofoam and make the cutting process more efficient.

Electric foam cutters are also popular choices for thicker Styrofoam. These tools offer more power and control, allowing for quicker and more accurate cuts. For larger pieces of thick Styrofoam, a jigsaw with a fine-toothed blade can be employed. However, it’s important to use a slow cutting speed to prevent the Styrofoam from melting or deforming.

In addition to these tools, having a straight edge or ruler to guide the cut can enhance the accuracy and neatness of the final result. Safety precautions should always be taken when using any cutting tools, such as wearing protective eyewear and working in a well-ventilated area to avoid inhaling fumes. Depending on the size and thickness of the Styrofoam and the desired level of precision, one can choose from a variety of tools to achieve a successful cut.

Cutting tips

Tool Preparation

- Choose the right cutting tool, such as a hot wire cutter, a sharp serrated knife, or an electric foam cutter. Make sure the tool’s blade is sharp and in good condition.

- Prepare a ruler or other straight guide tool to ensure that the cut line is straight.

Correct Grip Posture

- For handheld knives, such as serrated knives, hold the handle tightly with your hand, keep your arm steady, and distribute the force evenly in your hand.

- When operating a hot wire cutter or power tool, hold it the way the tool is designed to ensure comfort and control.

Cutting Action

- Use steady, even pressure to cut. Avoid excessive force that may cause the material to break or the cut surface to be uneven.

- For straight cuts, advance the knife at a constant speed along the ruler or guide tool.

- If cutting a curve, change the cutting direction slowly and smoothly to maintain the continuity of the action.

Multiple Light Cuts

- For thicker Styrofoam, do not try to cut through at once. You can make shallow cuts in multiple times and gradually deepen them to achieve a more precise cutting effect.

Best Way to Cut Thick Styrofoam

Here are the cutting methods for Styrofoam of different thicknesses and densities:

Thin and low-density Styrofoam

For this type of Styrofoam, you can use an ordinary utility knife to complete the cutting.

- Preparation: Place the Styrofoam flat on a stable workbench and press it with a heavy object to prevent it from moving.

- Cutting skills: Use a ruler to assist, and move the utility knife along the edge of the ruler at a constant speed with less pressure to complete the cutting in one go.

Styrofoam of medium thickness and density

Hot wire cutting method:

- Preparation: Set up the hot wire cutting equipment and ensure that the power connection is normal.

- Operation: Fix the Styrofoam, slowly move the Styrofoam close to the hot wire, let the hot wire gradually cut into the material, and pay attention to controlling the speed and cutting angle to obtain a straight cutting line.

Serrated knife cutting method:

- Choose a sharp serrated knife with finer teeth on the blade.

- When cutting, hold the handle with both hands, apply moderate pressure, and gradually cut through the material in multiple times.

Thick and high-density Styrofoam

Electric foam cutter:

- Adjust the cutting depth and angle settings as needed.

- After fixing the Styrofoam, turn on the power and move the cutter at a constant speed to cut.

Electric saw cutting:

- Use a fine-toothed electric saw blade suitable for foam materials.

- Keep the electric saw stable during the cutting process, and also cut in multiple times, cutting into a certain depth each time to avoid cutting through at one time, causing the material to break or the cut surface to be uneven.

Regardless of the thickness and density of Styrofoam you are dealing with, pay attention to safety, wear protective equipment, and operate in a well-ventilated environment.

Safety Precaution

Here are some safety precautions when cutting thick Styrofoam:

- Protective equipment: Wear goggles to prevent debris from entering the eyes, and wear gloves to protect the hands from cuts and abrasions.

- Good ventilation: Make sure the work area is well ventilated to reduce the accumulation of dust and possible harmful gases generated by cutting.

- Tool inspection: Before using the cutting tool, carefully check whether it is intact, whether the wire is broken, and whether the blade is sharp and firmly installed.

- Stable placement: Place the thick Styrofoam firmly on a stable workbench to prevent it from moving during cutting and causing accidents.

- Avoid overloading: Follow the rated power and instructions of the cutting tool to avoid tool failure or danger caused by overloading.

- Fire prevention measures: Styrofoam is flammable, so keep away from open flames and high temperature sources such as candles, stoves, etc. when cutting.

- Keep away from children: Make sure there are no children in the cutting work area to avoid accidental injuries.

- Power safety: If you use an electric cutting tool, keep your hands dry when plugging and unplugging the power plug to prevent electric shock.

- Cutting direction: Follow the design and safe operation guidelines of the tool to determine the correct cutting direction and avoid danger caused by reverse operation.

- End of work: After cutting, turn off the power in time, store the tool properly, and clean up the debris in the work area.

Always keep safety in mind, follow these precautions to minimize the risk of accidents when cutting thick Styrofoam.

Environmental Considerations

Styrofoam materials consume a lot of energy and resources during production and also cause pollution. It is difficult to degrade naturally, exists in the environment for a long time, and some additives may harm organisms. When cutting and using Styrofoam, in order to reduce the environmental impact, it should be used less, actively recycled, control the source, optimize the cutting method, safely handle waste, improve environmental awareness, and support relevant environmental policies. Researching, developing and promoting more environmentally friendly materials and improving processing technologies are crucial to solving its environmental problems.

Conclusion

The best way to cut thick Styrofoam depends on many factors. Hot wire cutting is a common and effective choice that can achieve precise and clean cuts, but be careful to control the temperature and cutting speed. When using a sharp serrated knife or an electric foam cutter, you need to maintain a steady grip and apply force evenly, and you can make multiple light cuts to achieve the desired effect.

No matter which method you choose, make sure the material is firmly placed before cutting, and prepare auxiliary tools such as a ruler to ensure that the cutting line is straight. At the same time, be sure to pay attention to safety during cutting, wear goggles and gloves, ensure that the work area is well ventilated, and stay away from open flames and high temperature sources to avoid the risk of electric shock and fire. In addition, different cutting strategies should be flexibly used according to specific needs and tool characteristics to obtain smooth and accurate cutting results.

Click on our website for more information.