The semi-automatic curing silo is still cumbersome when manual switching, and the lack of material can’t be adjusted automatically in time when the equipment is produced. Therefore, a fully automatic centralized feeding system equipment is produced, which makes the silo area unattended production mode and guarantees the raw material curing time. First, first use advanced management production mode, making production controllable, safe and reliable.

EPS aging silos is an essential component in the manufacturing process of expanded polystyrene. It is a specially designed storage facility used to keep raw EPS beads, which are the main raw material for producing expanded polystyrene foam products. This type of storage facility comes with several unique features that make it an ideal option for the safekeeping and handling of EPS beads.

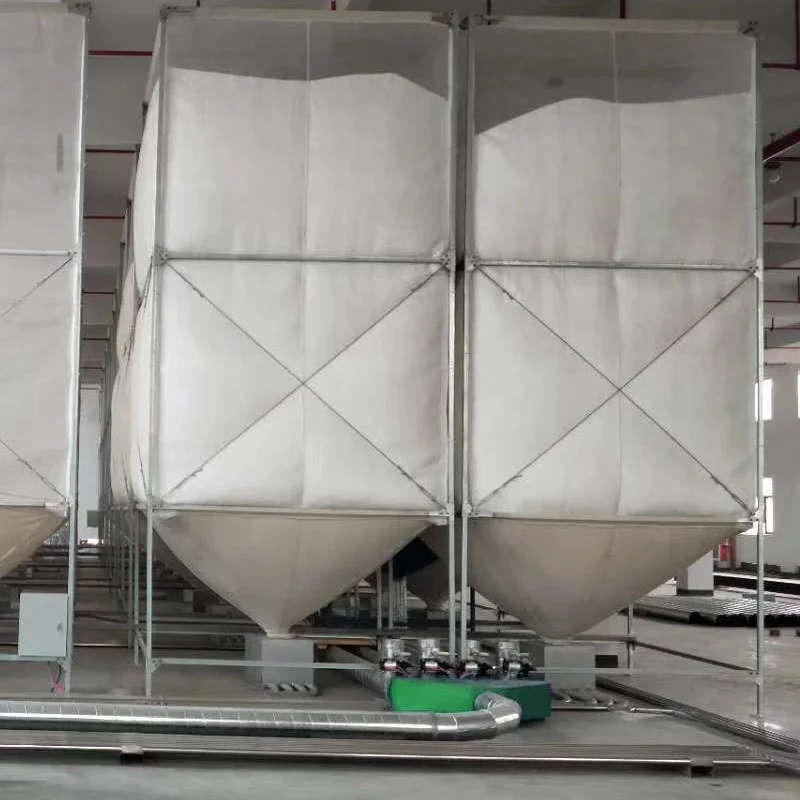

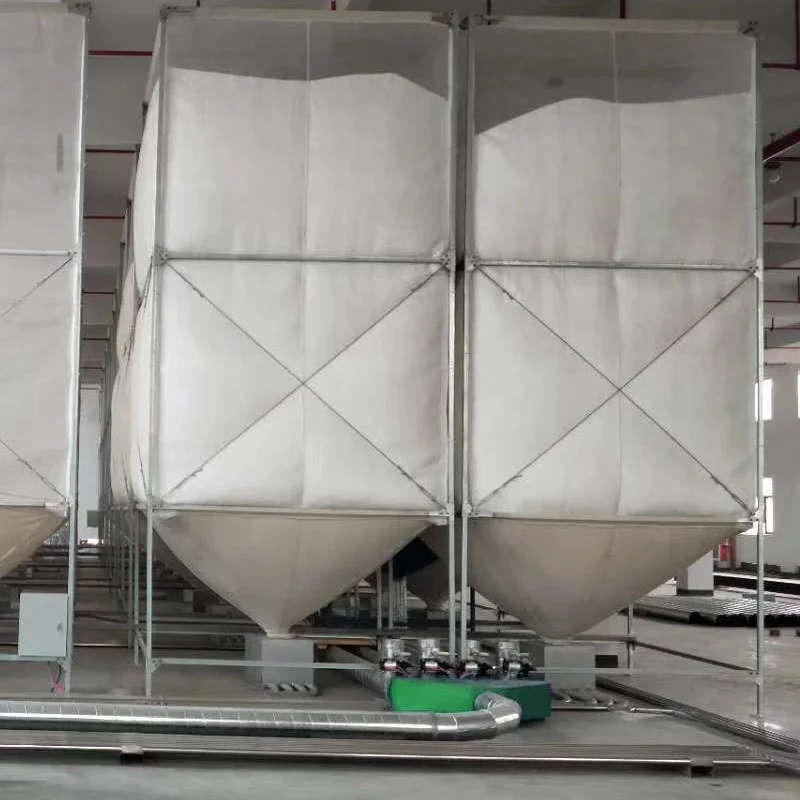

The primary advantage of an EPS aging silos is that it safeguards the EPS beads from moisture, dust, and other environmental factors that may cause degradation of the material. This is particularly important as even a small amount of moisture can ruin the properties of EPS beads and make them unusable. EPS material warehouse maintains an optimum temperature and relative humidity level to ensure the EPS beads remain in proper condition, thereby preventing production downtime and waste of materials. Another distinctive feature of EPS aging silos is the presence of an advanced material handling system. The loading and unloading of EPS beads are carried out with the help of a material handling system that minimizes the risk of contamination and damage. The material handling system also ensures that the process is efficient and ergonomic, making it easier for workers to handle and move the EPS beads safely and efficiently. EPS aging silos also has a well-organized storage system that ensures proper inventory management. The facility features multiple storage racks, which allow for a systematic arrangement of EPS beads based on their size, grade, or color. This makes it easier for manufacturing plants to keep track of their inventory, minimize waste, and have easy access to the required materials. In conclusion, the EPS aging silos play a crucial role in the production process of expanded polystyrene. It is an indispensable facility that provides an ideal environment for the safekeeping and handling of EPS beads. Its unique features like advanced material handling system, optimum temperature control, and well-organized storage system make it the ideal choice for manufacturing plants to maintain high standards of quality and efficiency.Auto Silo EPS Beads Storage is an automated system for storing expanded polystyrene (EPS) beads, ensuring efficient organization and retrieval in a controlled environment.

Automated: Auto Silo EPS Beads Storage utilizes automated systems for loading, unloading, and organizing EPS beads, reducing manual labor and increasing efficiency. Touch Screen and PLC

Level sensors (up location sensor, down location sensor).

Controlled Environment: It provides a controlled environment, maintaining optimal conditions for storing EPS beads to prevent degradation and maintain quality.

Space Optimization: The system optimizes space utilization by stacking EPS beads vertically, maximizing storage capacity within limited floor space.DN150/DN200 diameter galvanized pipe as a whole EPS transportation system.

Inventory Management: Fireproof EPS silo storage bags.It enables precise inventory tracking and management, allowing for real-time monitoring of bead levels and efficient retrieval when needed.

Customizable Configurations: Auto Silo EPS Beads Storage offers customizable configurations to accommodate different storage capacities and operational requirements, providing flexibility for various applications.

The auto silo EPS beads storage system is equipped with automated loading and unloading mechanisms, streamlining the process and minimizing manual labor.

Integrated sensors continuously monitor the silo's capacity, providing real-time data on bead levels and ensuring optimal storage conditions.

Specialized dust control measures prevent contamination of EPS beads during storage, maintaining their purity and quality for use in manufacturing processes.

The mechanical recycling machine typically uses mechanical processes such as crushing, shredding, and compacting to break down EPS foam waste into smaller pieces. It may include equipment such as crushers, granulators, and densifiers to facilitate the recycling process.

Chemical recycling machines employ chemical processes to break down EPS foam waste into its constituent molecules, which can then be used to produce new materials or products. They may utilize solvents, catalysts, or other chemical agents to depolymerize EPS foam and extract useful components.

EPS foam is widely used in retail and consumer product packaging, such as protective packaging for electronics, furniture, and household goods. EPS recycling machines enable the recycling of EPS foam packaging waste generated by retailers and consumers, supporting sustainable packaging initiatives and reducing landfill waste.

cutting-edge automation

ensuring precise inventory control

We are leading EPS manufacturer to provide all-in-one EPS solutions for your EPS project. Welcome to contact us at any time if you are looking for EPS machine, EPS material and many other EPS related product, please feel free to contact us now to get instant help.

Copyright © 2024 Hangzhou Epsole technologies Co.Ltd.

WhatsApp us