Expanded polypropylene is widely used across automotive, packaging, and industrial applications due to its lightweight structure and impact resistance. To meet different design and performance needs, manufacturers rely on specialized cutting technologies. Understanding how EPP foam cutting works is essential for achieving consistent shapes, tight tolerances, and efficient production outcomes.

Among the most common methods are CNC cutting, hot wire cutting, and die cutting. Each technique offers distinct advantages depending on part complexity, volume requirements, and surface finish expectations. This guide explains how these EPP foam cutting methods work, helping you choose the right solution for your specific manufacturing project.

What is EPP Foam Cutting?

EPP foam cutting is the process of shaping expanded polypropylene foam into precise components for industrial, automotive, and packaging applications. Because EPP is lightweight, resilient, and impact resistant, accurate cutting methods are essential to maintain its structural integrity, dimensional consistency, and performance during manufacturing and end use.

- Benefits of Accurate Cutting: Accurate cutting boosts product consistency, reduces material loss, and improves production efficiency. Controlled processes maintain uniform density, prevent deformation, and ensure components perform reliably under repeated impact, vibration, and long-term use.

- Definition and Purpose: EPP foam cutting uses mechanical and thermal techniques to turn raw foam blocks into finished parts, ensuring accurate dimensions, repeatable shapes, and smooth surfaces while preserving cushioning properties, strength, and durability for industrial applications.

- Common Cutting Methods: CNC machining, hot wire cutting, and die cutting are common methods. Each is chosen based on part complexity, production volume, and tolerance needs to ensure efficiency, minimize waste, and maintain consistent quality.

- Key EPP Applications: EPP cutting supports automotive energy absorbers, protective packaging, insulation components, and reusable trays. Precise cutting creates custom-fit parts that enhance protection, improve assembly efficiency, and meet strict performance standards.

EPP Cutting Methods

EPP cutting methods transform expanded polypropylene foam into precise shapes for automotive, packaging, and industrial applications. Different techniques—CNC cutting, hot wire cutting, and die cutting—offer unique advantages in accuracy, efficiency, and production scale.

Understanding each method helps manufacturers choose the right process, reduce material waste, maintain foam integrity, and produce components that meet strict design and performance standards.

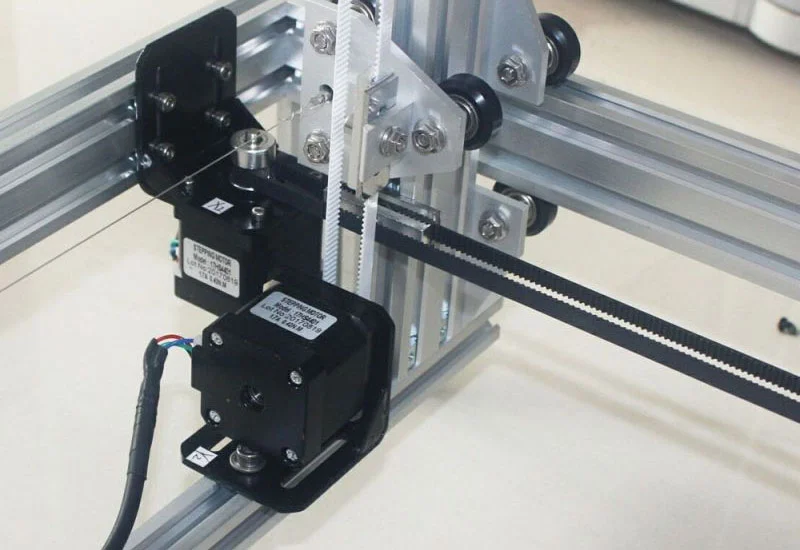

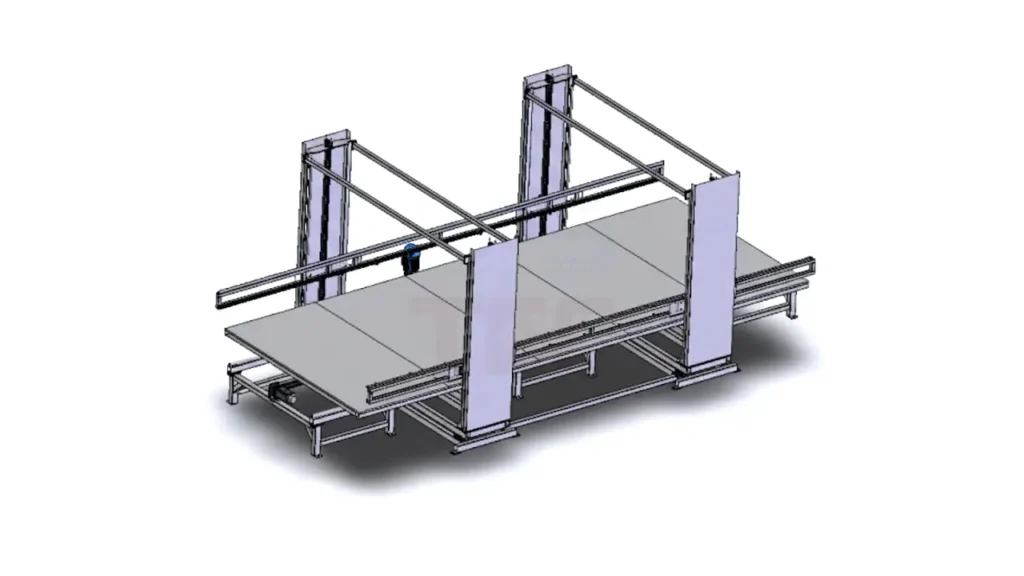

EPP Cutting CNC

EPP Cutting CNC uses computer-controlled machines to carve expanded polypropylene foam into precise shapes. This advanced method is ideal for producing prototypes, custom designs, and complex components with tight tolerances. CNC cutting ensures consistent quality, reduces material waste, and supports repeatable production, making it widely used in automotive, packaging, and industrial manufacturing applications.

EPP Cutting CNC handles complex geometries that are hard to achieve manually. Digital programming allows precise cutting paths, resulting in clean edges, accurate dimensions, and uniform surfaces. This method is widely applied in automotive parts, packaging inserts, and industrial components requiring high precision.

Benefits:

- High precision for complex shapes, producing detailed components with minimal errors and consistent quality across all parts.

- Consistent repeatability ensures every piece meets strict dimensional and design specifications, critical for large-scale production.

- Reduces material waste by optimizing cutting paths, lowering costs and improving efficiency in foam utilization.

- Supports complex and customized designs, offering flexibility for unique industrial or packaging applications.

- Minimal manual labor required, reducing human error and speeding up production for faster turnaround times.

EPP Cutting Hot Wire

EPP Cutting Hot Wire melts foam along a heated wire to create precise and smooth cuts. It is particularly effective for simple shapes, curves, and low-volume production. Hot wire cutting minimizes material waste and preserves foam integrity, making it ideal for prototyping, custom packaging, and specialized components where efficiency and quality are essential.

The heated wire passes through the foam effortlessly, producing clean edges and reducing the risk of tearing. EPP Cutting Hot Wire is energy-efficient, easy to set up, and cost-effective, making it suitable for small-scale manufacturing or specialized foam components.

Benefits:

- Smooth, clean edges for simple and curved shapes, producing finished parts with minimal post-processing required.

- Minimal material waste ensures cost-effective production and reduces foam scraps that would otherwise go unused.

- Cost-effective and energy-efficient, providing reliable cutting performance while consuming minimal power.

- Quick setup for low-volume production, allowing rapid prototyping or custom orders with little downtime.

- Reduces the risk of foam tearing or crumbling, preserving structural integrity and maintaining consistent product quality.

EPP Cutting Die

EPP Cutting Die uses a shaped metal die to stamp or press foam into specific forms. This method is excellent for high-volume production, creating repetitive parts quickly while maintaining uniformity and accuracy. Die cutting reduces manual labor and ensures reliable results, making it ideal for automotive inserts, protective packaging, and industrial components.

This method is highly effective for standard shapes like trays, pads, and protective inserts. Consistent pressure ensures clean separation from foam sheets without damaging material, making EPP Cutting Die ideal for industries requiring bulk components with reliable performance.

Efficient for standard, repetitive designs, suitable for packaging, automotive, and industrial applications requiring large quantities.

Benefits:

- Fast production for high-volume runs, allowing manufacturers to meet tight deadlines and scale efficiently.

- Uniform and consistent part shapes ensure all pieces meet quality standards for seamless assembly.

- Reduces manual labor by automating repetitive cutting tasks, lowering costs and minimizing errors.

- Maintains structural integrity, producing durable components that withstand impact, compression, and repeated use.

How to Choose Proper EPP Cutting Methods?

Choosing the right EPP cutting method is essential for efficiency, precision, and material conservation. Different applications, production volumes, and part complexities require specific techniques. Understanding the strengths and limitations of CNC, hot wire, and die cutting allows manufacturers to select the most suitable method, ensuring high-quality components while reducing costs and waste.

Budget and Equipment Availability: Factor in the cost of machines, setup, and maintenance. CNC machines are more expensive but offer precision, hot wire is low-cost and simple to operate, and die cutting requires initial die investment but is cost-effective for mass production. Balance investment with expected returns.

Consider Part Complexity: Evaluate the shape, size, and design details of the EPP component. CNC cutting is ideal for intricate or customized designs, hot wire cutting works for simple curves, and die cutting is best for standard repetitive shapes. Selecting the right method ensures precision and minimal errors.

Assess Production Volume: Determine how many parts you need. High-volume runs benefit from die cutting due to speed and uniformity. Low to medium volumes can use CNC or hot wire cutting, which are more flexible for custom shapes and prototyping, balancing quality and cost.

Material Efficiency: Consider how much foam may be wasted during cutting. CNC and hot wire cutting minimize waste for custom shapes, while die cutting is efficient for bulk production. Choosing a method that reduces scrap helps lower costs and supports sustainable production practices.

Required Accuracy and Finish: Decide on the tolerance and edge quality required for the final product. CNC cutting provides the highest precision, hot wire delivers smooth curves, and die cutting ensures consistent shapes. Matching the method to quality requirements prevents defects and rework.

How Does Heat Affect EPP Foam During Cutting?

EPP foam is sensitive to heat, and excessive heat can cause melting or deformation of the material. Proper temperature control and cutting speeds are essential to prevent damage and ensure clean cuts without compromising the foam’s properties.

What are the common methods used for EPP foam cutting?

The common methods for EPP foam cutting include hot wire cutting, water jet cutting, CNC routing, and die cutting. Each method offers unique advantages and is suitable for different applications and cutting requirements.

How does hot wire cutting work for EPP foam?

Hot wire cutting involves using a heated wire to slice through EPP foam. The wire heats up to a specific temperature, allowing it to melt through the foam with precision, resulting in clean and smooth cuts without causing damage to the material.

What safety precautions should be taken during EPP foam cutting?

When cutting EPP foam, it is essential to wear appropriate personal protective equipment (PPE), ensure proper ventilation in the cutting area, and follow manufacturer guidelines for equipment operation and maintenance to ensure safety.

Conclusion

EPP foam cutting plays a crucial role in transforming raw foam blocks into functional components. CNC cutting delivers excellent precision for complex designs, hot wire cutting ensures smooth edges for simple shapes, and die cutting supports fast, high-volume production. Selecting the right method directly impacts efficiency, accuracy, and overall product performance.

Understanding these cutting techniques allows manufacturers to optimize material usage and reduce waste. By matching the cutting process to application needs, businesses can improve consistency, shorten lead times, and maintain reliable quality across different EPP foam products in demanding industries.

For businesses looking to scale production, investing in reliable equipment is key. You can get wholesale EPP cutting machines from our epsole to support CNC, hot wire, and die cutting processes. Our solutions are designed to enhance productivity, support customization, and meet long-term manufacturing demands.