EPS Panel Weight plays a crucial role in construction and insulation performance. The weight of the panels affects structural strength, ease of handling, and installation efficiency. Lighter panels are easier to transport and install, while heavier panels often offer increased density and durability, making them suitable for long-lasting construction projects.

Understanding the impact of EPS Panel Weight also helps optimize thermal insulation. Heavier panels generally provide better insulation due to higher density, while lighter panels are ideal for applications requiring less structural load. Choosing the right weight ensures energy efficiency, reduces construction costs, and meets the specific needs of residential, commercial, or industrial projects.

What is EPS Panel Weight?

EPS panel weight refers to the mass of an Expanded Polystyrene (EPS) panel, determined by its density and thickness.

It affects the panel’s insulation performance, structural strength, and ease of handling. Lighter panels are easy to install, while heavier panels offer greater durability, stability, and enhanced thermal efficiency for construction projects.

How to Measure EPS Panel Weight?

To accurately plan construction and ensure proper insulation, knowing the weight of your EPS panels is essential. EPS Panel Weight affects handling, structural support, and thermal performance.

Measuring it correctly allows builders and contractors to select the right panels for specific applications, avoid installation issues, and maintain safety standards while optimizing energy efficiency.

Tools Needed

- Digital scale or balance

- Measuring tape or ruler

- Calculator

- Notebook and pen

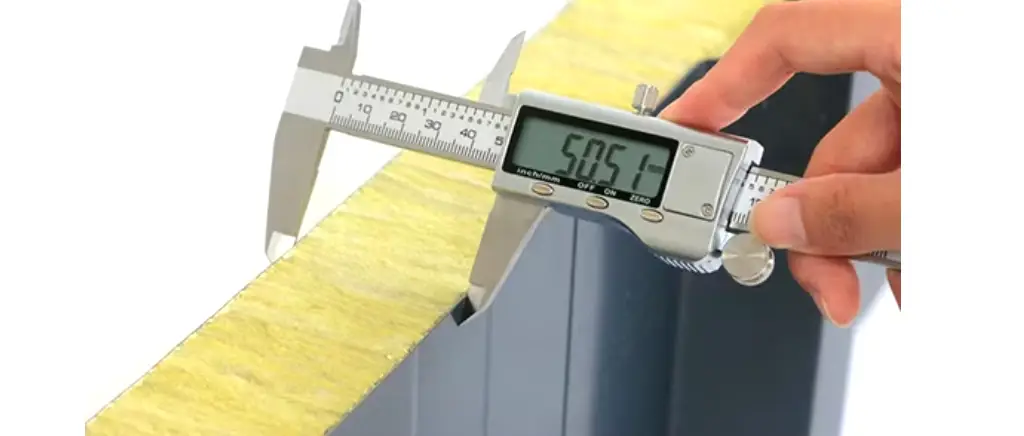

Step 1: Measure Panel Dimensions

To calculate EPS panel weight, start by measuring its length, width, and thickness accurately using a measuring tape or ruler. Record each measurement in consistent units, such as meters or centimeters. Precise dimensions are critical, as small errors can significantly affect the weight calculation and lead to inaccurate results for construction planning.

Next, double-check your measurements for consistency. Ensure the panel is placed on a flat surface and that the measuring tape is taut to avoid bending or gaps. Accurate dimension data will serve as the foundation for calculating volume, which is essential for determining the panel’s total weight and density effectively.

Step 2: Calculate Panel Volume

Once dimensions are recorded, calculate the EPS panel’s volume by multiplying length × width × thickness. This gives the panel’s cubic measurement, usually in cubic meters or centimeters. Volume calculation is a crucial step, as it directly influences the weight estimate, helping builders understand handling and insulation properties.

It’s important to convert all measurements to the same unit system before multiplying to maintain accuracy. Document the calculated volume carefully in your notebook, as this will be used with density values to determine the panel’s total weight. Accurate volume ensures reliable results for purchasing and construction decisions.

Step 3: Determine Panel Weight

To find the EPS panel weight, multiply the calculated volume by the panel’s density, usually given in kg/m³. This gives the total mass of the panel, which informs structural planning, insulation efficiency, and handling requirements during installation. Using correct density values ensures precise weight assessment for construction needs.

Verify the density value with the manufacturer or product specifications to avoid errors. Record the final weight in your notebook and compare with standard weight ranges for EPS panels. Accurate weight determination helps contractors choose the right panels for their projects, ensuring both safety and efficiency during construction.

EPS Panel Weight Factors

EPS panel weight depends on multiple factors that influence its performance, durability, and insulation efficiency. Understanding these factors helps builders and contractors select panels that meet structural requirements while ensuring energy efficiency. Considering density, thickness, and application purpose is key to achieving optimal results in construction projects.

Application Purpose: The intended use—walls, roofs, or flooring—affects the optimal panel weight. Load-bearing areas require heavier, denser panels, while non-structural applications may use lighter panels. Matching panel weight to application ensures safety, efficiency, and the best insulation performance for each construction scenario.

Density: The density of EPS panels directly affects their weight and insulation properties. Higher-density panels are heavier, offering improved thermal resistance and structural strength. Lower-density panels are lighter and easier to handle but may provide less insulation. Choosing the right density ensures a balance between performance and practicality.

Thickness: Thicker panels naturally weigh more and provide better insulation. The thickness should match the building’s energy efficiency requirements and load-bearing needs. Selecting panels with appropriate thickness ensures long-term durability, reduces energy costs, and meets building regulations while maintaining ease of installation.

Panel Size: Larger panels weigh more due to their increased surface area. Size impacts transportation, handling, and installation methods. Correct panel sizing helps reduce labor costs and installation time while maintaining structural integrity and insulation efficiency, making projects more efficient and cost-effective.

Additives and Coatings: Some EPS panels include fire retardants, moisture barriers, or other additives that increase weight slightly. These modifications enhance safety, durability, and performance. Considering additives ensures panels meet project-specific requirements while maintaining the right balance between weight and functionality.

How to Choose EPS Panel Weight?

Choosing the right EPS panel weight is crucial for balancing insulation, structural support, and ease of installation. The correct weight ensures durability, energy efficiency, and cost-effectiveness. Builders and contractors must consider project type, load-bearing requirements, and environmental conditions to select panels that meet performance and safety standards.

- Environmental Factors: Consider exposure to moisture, wind, and temperature fluctuations. EPS panels with the right weight can resist deformation, provide stability, and maintain insulation properties in varying conditions. Proper selection prevents future damage and enhances the lifespan of the construction project.

- Project Requirements: Determine the purpose of the panels—walls, roofs, or flooring—and the expected load. Lighter panels are ideal for non-structural applications, while heavier panels provide strength and stability for load-bearing structures. Selecting panels suited to the specific use ensures optimal performance and safety.

- Thermal Insulation Needs: Heavier panels typically offer higher density, improving insulation and energy efficiency. Consider climate conditions and thermal requirements of the building. Choosing panels with the appropriate density helps maintain indoor comfort, reduces heating or cooling costs, and ensures compliance with building standards.

- Ease of Handling and Installation: Lightweight panels reduce labor and transportation costs and simplify installation in hard-to-reach areas. Heavier panels may require specialized equipment but provide enhanced durability. Balancing ease of handling with performance needs ensures efficient construction without compromising quality.

- Budget and Cost Considerations: Heavier panels usually cost more due to higher material density. Evaluate your budget alongside project requirements to make a cost-effective choice. Investing in the right weight ensures long-term savings through energy efficiency, reduced maintenance, and lower risk of structural issues.

Conclusion

Choosing the correct EPS Panel Weight is essential for balancing strength, insulation, and construction efficiency. By understanding the differences between light and heavy panels, builders can ensure optimal performance in walls, roofs, and flooring. The right panels contribute to durability, energy savings, and long-term project success.

Proper EPS Panel Weight selection also impacts installation time and labor costs. Lightweight panels allow faster handling, while heavier, denser panels enhance stability and insulation properties. Evaluating your project requirements carefully ensures you select panels that meet both structural and thermal demands, providing the best results for every construction scenario.

For those looking to source EPS panels efficiently, our Epsole offers wholesale options tailored to your project needs. Get high-quality panels in various weights to suit insulation and construction requirements, ensuring cost-effective and reliable solutions for builders, contractors, and developers alike.