Welcome to your comprehensive guide to PVC pipes! Whether you’re a homeowner, contractor, or simply curious about this versatile material, you’ve come to the right place.

In this blog, we’ll delve into the world of PVC pipes, exploring everything from their composition and uses to their benefits and installation. We’ll also provide practical tips and advice to help you make informed decisions when working with PVC.

What Is PVC Pipe?

PVC pipe, or polyvinyl chloride pipe, is a versatile thermoplastic material widely used in various applications, including water supply, sewer systems, drainage, and industrial piping.

What Is PVC Pipe Made of?

PVC pipes are made of polyvinyl chloride (PVC). This is a synthetic plastic that is durable, resistant to corrosion, and has a long lifespan. PVC pipes are commonly used in various applications, including plumbing, electrical wiring, and construction.

It is known for its durability, corrosion resistance, and ease of installation. PVC pipes are typically classified into two main categories:

- Rigid PVC Pipes: These pipes are known for their strength and durability, making them suitable for applications such as water supply, sewer systems, and industrial piping.

- Corrugated PVC Pipes: These pipes have a corrugated structure, providing additional flexibility and strength, making them ideal for drainage systems and storm water management.

PVC pipes offer several advantages, such as:

- Recyclable: PVC is a recyclable material.

- Durability: PVC is resistant to corrosion, chemicals, and UV rays.

- Lightweight: PVC pipes are lightweight, making them easy to handle and install.

- Cost-Effective: PVC pipes are generally more cost-effective than other pipe materials.

- Ease of Installation: PVC pipes are easy to join using solvent welding or mechanical fittings.

- Low Maintenance: PVC pipes require minimal maintenance.

What Is PVC Pipe Used for?

PVC (polyvinyl chloride) pipes have a wide range of applications due to their versatility, durability, and resistance to corrosion. Here’s a more in-depth look at some of their primary uses:

Plumbing

- Water supply: PVC pipes are used to transport potable water from sources to homes, businesses, and other structures. Their smooth interior surface minimizes friction, ensuring efficient water flow.

- Wastewater: PVC pipes are also used for sewer lines, transporting wastewater from homes and businesses to treatment facilities. Their resistance to corrosion helps prevent leaks and clogs.

- Drainage: PVC pipes are used for drainage systems, such as storm drains, to collect and transport rainwater and other surface water.

Electrical

- Conduit: PVC conduits are used to protect electrical wires from damage and moisture. They come in various sizes and are often used in residential, commercial, and industrial buildings.

- Cable sheathing: PVC is used to sheath cables, providing insulation and protection. This is particularly common in telecommunications and computer networks.

Industrial Applications

- Chemical processing: PVC pipes are used in chemical plants to transport corrosive liquids and gases. Their resistance to chemicals makes them ideal for such applications.

- Manufacturing: PVC pipes are used in various manufacturing processes, such as food processing and pharmaceutical production.

- Wastewater treatment: PVC pipes are used in wastewater treatment plants to transport and treat wastewater.

Other Uses

- Irrigation: PVC pipes are used in irrigation systems to transport water to crops and lawns.

- Ventilation: PVC pipes are used in ventilation systems to circulate air.

- Marine applications: PVC pipes are used in marine applications, such as bilge pumps and plumbing systems on boats.

PVC pipes offer a durable, cost-effective, and versatile solution for a wide range of applications. Their properties make them a popular choice in construction, plumbing, electrical, and industrial sectors.

How are PVC Pipes Made?

PVC pipes are made through a process called extrusion. Here’s a breakdown of the steps involved:

- Raw Material Preparation: PVC resin powder is mixed with plasticizers, stabilizers, and other additives to create a compound that can be extruded.

- Extrusion: The compound is fed into a large extruder, where it is heated and melted. The melted material is then forced through a die, which shapes it into a pipe.

- Cooling and Sizing: The extruded pipe is cooled and sized to ensure it meets the required dimensions and specifications.

- Cutting and Packaging: The pipe is cut to the desired length and packaged for shipping.

The specific steps and processes involved in PVC pipe manufacturing may vary depending on the type of pipe, the manufacturer, and the specific requirements. However, the basic principles remain the same.

What Sizes Does PVC Pipe Come In?

PVC pipes come in a wide range of sizes, typically measured in inches or millimeters. The specific sizes available can vary depending on the manufacturer and intended use.

Common sizes in inches include:

- 1/2 inch

- 3/4 inch

- 1 inch

- 1 1/2 inch

- 2 inch

- 3 inch

- 4 inch

- 6 inch

Larger sizes are also available for specific applications.

It’s important to select the appropriate size for your project to ensure proper functionality and efficiency.

What Are the Benefits of PVC Pipes?

PVC pipes offer several significant benefits:

- Durability: PVC is a strong and durable material that can withstand harsh weather conditions, chemicals, and mechanical stress. This makes PVC pipes long-lasting and resistant to corrosion.

- Cost-effective: PVC pipes are generally more affordable than other materials like metal, making them a cost-effective choice for many applications.

- Easy installation: PVC pipes are lightweight and easy to cut, join, and install. This reduces labor costs and installation time.

- Low maintenance: PVC pipes require minimal maintenance and do not need to be painted or coated.

- Fire resistance: PVC pipes are generally considered fire-resistant, meaning they do not contribute to the spread of fire.

- Chemical resistance: PVC pipes are resistant to a wide range of chemicals, making them suitable for use in industrial applications.

- Efficiency: PVC pipes have a smooth interior surface that reduces friction, allowing for efficient flow of liquids and gases.

These benefits make PVC pipes a popular choice for plumbing, electrical wiring, construction, and industrial applications.

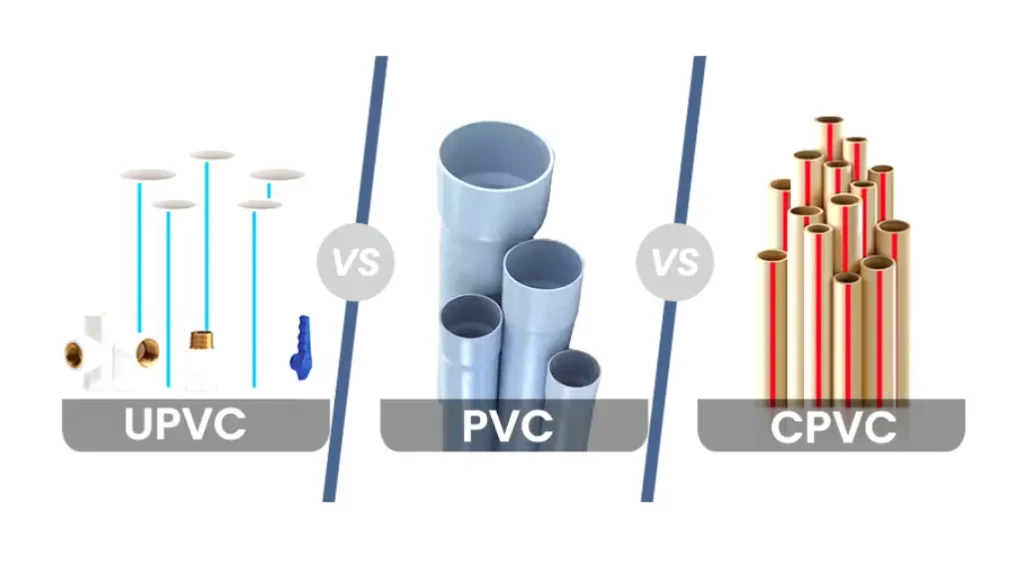

What Are the Differences Between PVC, CPVC and UPVC?

PVC (Polyvinyl Chloride), CPVC (Chlorinated Polyvinyl Chloride), and UPVC (Unplasticized Polyvinyl Chloride) are all types of vinyl plastics used in various applications, particularly in construction and plumbing. While they share a common base material, PVC, they have distinct properties and uses.

PVC (Polyvinyl Chloride)

- General-purpose PVC: This is the most common type of PVC, used in a wide range of applications including pipes, fittings, window frames, and siding.

- Properties: Durable, resistant to chemicals, and relatively inexpensive.

- Limitations: Can become brittle at low temperatures and may not be suitable for high-temperature applications.

CPVC (Chlorinated Polyvinyl Chloride)

- Enhanced properties: CPVC is a modified form of PVC with added chlorine. This modification improves its heat resistance, making it suitable for hot water applications.

- Applications: Commonly used for hot water supply lines, radiant heating systems, and industrial piping.

- Properties: Higher heat resistance, durable, and resistant to chemicals.

UPVC (Unplasticized Polyvinyl Chloride)

- Rigid form: UPVC is a rigid form of PVC that does not contain plasticizers. This makes it more durable and resistant to deformation.

- Applications: Primarily used for window and door frames, piping systems, and other applications requiring a rigid, durable material.

- Properties: Highly rigid, durable, and resistant to weathering.

Key Differences:

| Feature | PVC | CPVC | UPVC |

|---|---|---|---|

| Heat resistance | Moderate | High | High |

| Flexibility | Moderate | Moderate | Low |

| Durability | Good | Good | Excellent |

| Applications | General-purpose | Hot water, industrial piping | Window frames, piping |

PVC, CPVC, and UPVC are all versatile materials with unique properties. The choice between them depends on the specific requirements of the application, such as temperature tolerance, durability, and cost.

Conclusion

PVC pipes have become an essential component of modern construction and infrastructure due to their versatility, durability, and cost-effectiveness. From plumbing systems to electrical wiring and industrial applications, PVC pipes offer reliable and efficient solutions.

By understanding the properties, uses, and benefits of PVC pipes, you can make informed decisions when selecting materials for your projects. Whether you’re a homeowner, contractor, or engineer, PVC pipes provide a valuable and dependable option.

Ready to take your PVC pipe project to the next level? Contact us today to get wholesale pricing on high-quality PVC pipes. Our team of experts can assist you in selecting the right products and ensuring a successful installation.

Let’s build a stronger future together with PVC pipes!