In this blog post, we embark on a journey to unravel the mysteries surrounding the triggers that cause a pressure relief valve to go off. From the subtle shifts in system dynamics to the sudden surges in pressure, we delve deep into the factors that compel the PRV to act, ensuring the safety and integrity of industrial processes.

Let’s dive into the questions about what causes a pressure relief valve to go off.

What Is Pressure Relief Valve

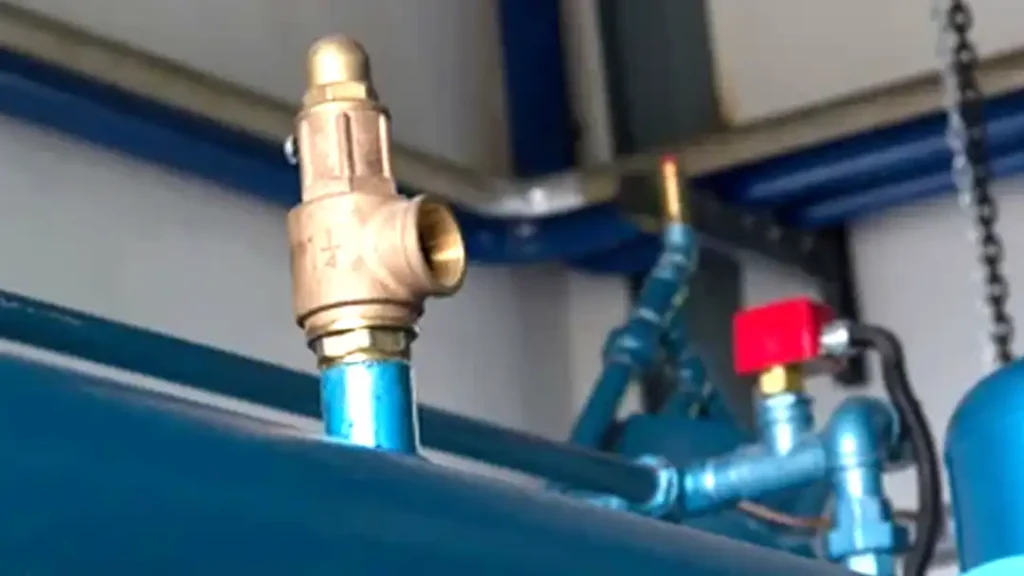

A pressure relief valve (PRV) is a safety device designed to protect pressure vessels and systems from exceeding their maximum allowable pressure limits. Here’s a detailed explanation of what a pressure relief valve is and how it functions:

Purpose of Pressure Relief Valve:

The primary purpose of a pressure relief valve is to release excess pressure from a system to prevent equipment damage, explosions, or other hazardous situations. It acts as a safeguard, ensuring that the pressure within a system remains within safe operating limits.

Pressure Relief Valve Failure Rate

The failure rate of pressure relief valves is an important consideration in the maintenance and reliability of pressure systems. Several factors influence this rate, including the quality of the valve, the conditions in which it operates, and the maintenance practices employed. Here are key points about the failure rate of pressure relief valves:

- Manufacturing Quality: High-quality valves manufactured by reputable companies generally have lower failure rates. Inferior materials or manufacturing defects can significantly increase the likelihood of failure.

- Operating Conditions: Valves operating under extreme conditions, such as high pressures, temperatures, or corrosive environments, are more prone to failure. The more severe the operating conditions, the higher the stress on the valve components, leading to increased wear and tear.

- Maintenance Practices: Regular maintenance and inspection are crucial in identifying and addressing potential issues before they lead to valve failure. Poor or infrequent maintenance can result in higher failure rates due to undetected wear, corrosion, or other damage.

- Usage Frequency: Valves that are frequently cycled (opened and closed often) or remain in constant operation are subject to more wear and tear, which can lead to higher failure rates compared to valves used less frequently.

- Installation Quality: Proper installation is critical for ensuring the correct functioning of pressure relief valves. Incorrect installation can lead to premature failure due to misalignment, inadequate sealing, or other issues.

- Environmental Factors: External factors such as vibration, humidity, and exposure to chemicals can affect the longevity and reliability of pressure relief valves, contributing to higher failure rates.

While specific failure rates can vary widely depending on the above factors, industry data and studies often provide general benchmarks. For instance, a well-maintained pressure relief valve in a controlled environment may have a failure rate of less than 1% per year. Conversely, valves in harsh environments or with poor maintenance may experience significantly higher failure rates.

3 Signs Of Pressure Relief Valve Failure

System Cannot Reach Pressure:

When a pressure relief valve fails, one common sign is that the system it’s meant to regulate cannot reach the desired pressure. This occurs because the valve is stuck in an open position, allowing excess pressure to escape constantly. As a result, the system struggles to build up pressure to the desired level, causing inefficiency and potentially rendering the system ineffective for its intended purpose.

System is Over Maximum Pressure:

Conversely, another sign of pressure relief valve failure is when the system exceeds its maximum pressure limit. This happens because the valve fails to open when pressure within the system surpasses safe levels. Without the valve releasing excess pressure, the system becomes prone to damage, leakage, or even catastrophic failure due to the excessive stress exerted on its components. This situation poses significant safety risks to both equipment and personnel.

Pressure Relief Valve is Leaking or Has No Pressure:

Lastly, a visible indication of pressure relief valve failure is leakage or a complete absence of pressure release when it’s supposed to activate. Leaking can occur due to various reasons such as wear and tear, corrosion, or improper installation. On the other hand, if the valve fails to release pressure altogether, it compromises the safety of the entire system. Without this critical safety mechanism functioning properly, the system becomes vulnerable to dangerous pressure build-up, leading to potential accidents or equipment damage.

What Causes a Pressure Relief Valve to Go Off

A pressure relief valve is designed to activate and release excess pressure from a system to prevent over-pressurization and potential damage or failure. Several factors can cause a pressure relief valve to go off:

- Excessive Pressure Build-Up: The most common cause is when pressure within the system exceeds the predetermined set point of the relief valve. This can occur due to various factors such as malfunctioning equipment, blockages in pipelines, thermal expansion of fluids, or process upsets.

- Temperature Changes: Changes in temperature can lead to fluctuations in pressure within the system. If the relief valve is set to respond to pressure variations caused by temperature changes, it may go off to release excess pressure and maintain safe operating conditions.

- Equipment Malfunction: If the pressure relief valve itself malfunctions or becomes damaged, it may activate unexpectedly or fail to activate when needed. Malfunctions can occur due to wear and tear, corrosion, mechanical issues, or improper installation.

- System Design Flaws: In some cases, pressure relief valves may be improperly sized or installed, leading to ineffective operation. Design flaws such as undersized relief valves or inadequate venting can result in the valve going off more frequently or failing to adequately protect the system.

- Process Upsets or Changes: Changes in the operating conditions or process parameters can cause sudden pressure spikes within the system. Process upsets, such as valve failures, pump trips, or sudden changes in flow rates, can trigger the pressure relief valve to activate and prevent potential damage or hazards.

In summary, a pressure relief valve goes off to safeguard the integrity and safety of the system by releasing excess pressure. Understanding the causes of pressure relief valve activation is crucial for ensuring proper system operation, maintenance, and safety protocols.

What Causes a Pressure Relief Valve to Leak

Several factors can cause a pressure relief valve to leak:

- Wear and Tear: Over time, the components of a pressure relief valve can degrade due to normal wear and tear. Seals, gaskets, and other parts may develop cracks or become worn, leading to leaks.

- Corrosion: Exposure to corrosive substances or environments can corrode the materials of the valve, weakening its structure and causing leaks to occur. Corrosion is particularly common in valves installed in industrial settings or in systems that handle corrosive fluids.

- Improper Installation: Incorrect installation of the pressure relief valve, such as inadequate sealing or improper alignment, can create gaps or faults that allow leakage to occur.

- High Pressure Surges: Rapid pressure surges within the system can put excessive stress on the valve, causing damage to its components and resulting in leaks.

- Contaminants: Particles or debris present in the fluid flowing through the valve can cause abrasion or blockage, leading to leaks. Similarly, contaminants can also interfere with the proper functioning of the valve’s sealing mechanisms.

- Improper Maintenance: Neglecting regular maintenance, such as lubrication or inspection of the valve, can accelerate wear and deterioration, increasing the likelihood of leaks over time.

- Manufacturing Defects: Occasionally, defects in the manufacturing process or materials used to construct the valve can result in weak points or flaws that predispose the valve to leakage.

Addressing these issues typically involves regular inspection and maintenance of the pressure relief valve, prompt repair or replacement of damaged components, and ensuring proper installation practices are followed. Additionally, selecting a valve made from suitable materials for the specific application and operating conditions can help mitigate the risk of leakage.

Conclusion

In conclusion, several factors can cause a pressure relief valve to go off, including excessive pressure buildup, temperature fluctuations, mechanical issues, corrosion, improper installation or maintenance, and external factors such as power surges or seismic activity.

Proper design, installation, and maintenance practices, along with regular monitoring of system parameters, are essential for preventing unexpected activation of pressure relief valves and ensuring the safety and efficiency of pressure-bearing systems.

Addressing issues such as wear and tear, corrosion, contamination, and manufacturing defects can help minimize the risk of valve malfunction and maintain the integrity of the system.