Importing EPS Take Away Food Box EPS Making Machine from China

Are you looking for the EPS take away food box EPS making machine? Here in our EPS machine manufacturer, we can provide premium EPS take away food box making machine with a competitive pricing.

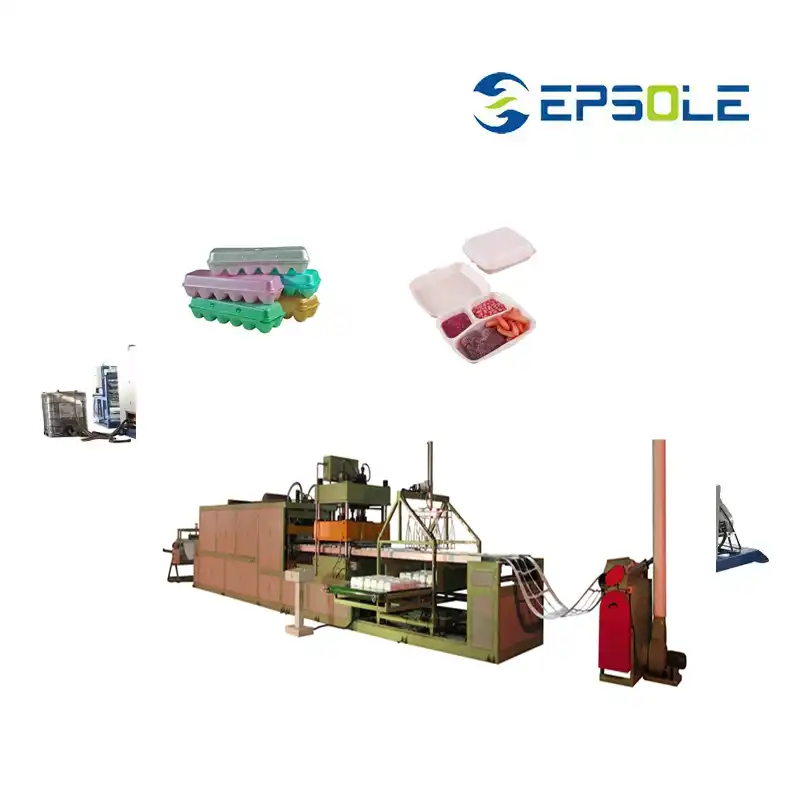

Our Take Away Food Box EPS Making Machine

The take away food box EPS making machine is designed to mold various types of food boxes for take away food, fast food, restaurant and etc, and this specific EPS making machine is to shape and mould foam products for food industry.

EPS Pre-Expander: This machine expands the EPS beads using steam and pressure, creating the raw material for the food boxes. It ensures uniform expansion for consistent product quality.

Shape Molding Machine: This machine molds the expanded EPS beads into the desired shape of the takeaway food box. It utilizes molds of various sizes and shapes to produce different types of boxes.

Automatic Forming: The machine is equipped with automatic forming capabilities, reducing manual labor and increasing production efficiency. It can produce a large number of food boxes in a short amount of time.

Temperature Control: Precise temperature control is essential in the EPS making process to ensure proper expansion and molding. The machine features temperature control systems to maintain optimal conditions throughout the production process.

High-Speed Production: Takeaway food box EPS making machines are designed for high-speed production to meet the demands of the food packaging industry. They can produce thousands of food boxes per hour, depending on the machine’s capacity.

EPS Fast Food Container Forming Machine

An EPS fast food container forming machine is a specialized piece of equipment used in the EPS manufacturing process of fast food containers made from Expanded Polystyrene (EPS). We are one of the leading eps fast food container forming machine factories to provide the specific eps fast food container forming machine to meet your requirement.

EPS Bead Preparation: The process typically begins with EPS beads, which are the raw material for making fast food containers. These beads are pre-expanded using steam and pressure in an EPS pre-expander machine. This step ensures that the beads are uniformly expanded and ready for the forming process.

Molded Container Formation: Once the EPS beads are prepared, they are fed into the fast food container forming machine. The machine uses molds of various sizes and shapes to mold the expanded EPS beads into the desired form of fast food containers. These containers can include clamshells, trays, cups, bowls, and other shapes commonly used in the fast food industry.

Heat and Pressure Application: The machine applies heat and pressure to the expanded EPS beads within the molds. This process softens the EPS material, allowing it to conform to the shape of the mold and form the desired container shape. The application of heat ensures that the formed containers have smooth surfaces and sharp edges, enhancing their appearance and functionality.

Cooling and Solidification: After the molding process, the formed containers are cooled to solidify the EPS material and maintain the shape of the containers. Cooling may be achieved through air cooling or water cooling methods, depending on the machine’s design and specifications.

Trimming and Finishing: Once the containers are cooled and solidified, they undergo trimming and finishing processes to remove any excess material and refine the container’s appearance. Trimming may involve cutting off excess EPS material or smoothing rough edges to achieve a clean and professional finish.

Quality Control and Inspection: Throughout the forming process, quality control measures are implemented to ensure that the produced fast food containers meet industry standards and specifications. This may include visual inspection, dimensional measurement, and testing for structural integrity and durability.

Take Away Food Box EPS Making Machine Functions

EPS Bead Expansion

One of the primary functions of the machine is to expand EPS beads using steam and pressure. This process ensures that the beads are uniformly expanded, creating the raw material needed for making takeaway food boxes.

Molding into Desired Shapes

Some EPS foam recycling machines feature an automatic sorting system that separates EPS foam waste from contaminants such as dirt, debris, and other non-recyclable materials. This helps to ensure that only clean and pure EPS foam material is processed for recycling.

Automated Forming

The take away food box eps making machine is equipped with automated forming capabilities. To produce a large volume of food boxes efficiently and consistently without requiring excessive manual labor. The automating the forming process enhances production speed and efficiency, meeting the demands of the food packaging industry.

Take Away Food Box EPS Making Machine Applications

Food Packaging Industry

One of the primary applications of EPS making machines is in the food packaging industry. These machines are used to produce a wide range of takeaway food boxes, including clamshells, trays, cups, bowls, and more. Takeaway food box EPS making machines help food businesses package their products securely for delivery and consumption, ensuring freshness and convenience for customers.

Fast Food Restaurants and Cafes

Fast food restaurants and cafes often rely on EPS making machines to produce disposable food containers for their takeaway and delivery services. These machines enable businesses to efficiently package their food items, such as burgers, fries, sandwiches, salads, and beverages, in hygienic and durable containers suitable for on-the-go consumption.

Food Delivery Services

With the rise of food delivery services, EPS making machines play a crucial role in producing packaging solutions for delivered meals. These machines enable restaurants, cloud kitchens, and food delivery platforms to package meals securely, maintaining food quality during transit and ensuring a positive customer experience.

Why Choose Our Take Away Food Box EPS Making Machine

Customization: We offer flexibility in production with customizable options for box size, thickness, and design. This allows you to cater to diverse customer needs and stand out in the market with unique packaging solutions.

Quality: Our machine ensures consistent quality in every food box produced. With advanced technology and quality control systems, you can trust that your products meet industry standards and regulations.

Energy Efficiency: We prioritize energy efficiency in our machine design, helping you reduce operational costs and environmental impact. By optimizing energy consumption, you can enhance sustainability while maintaining profitability.

Ease of Use: Our machine features a user-friendly interface and intuitive controls, making it easy to operate for both experienced operators and newcomers. With minimal training required, you can streamline production and focus on growing your business.

Reliability: We prioritize reliability in our machine construction, using high-quality materials and components to ensure durability and longevity. With proper maintenance, you can depend on our machine for consistent performance over time.

Support: We provide comprehensive support services to assist you every step of the way, from installation and training to troubleshooting and maintenance. Our dedicated team is committed to helping you succeed and maximizing the value of your investment.

FAQs about Take Away Food Box EPS Making Machine

What is EPS?

Expanded Polystyrene (EPS) is a lightweight, rigid plastic material commonly used in packaging applications. It is known for its excellent insulation properties and ability to cushion products during transportation.

How does an EPS making machine work?

An EPS making machine works by heating and expanding EPS beads with steam and pressure in a pre-expander. The expanded beads are then molded into the desired shape using a shape molding machine. The process involves heating, molding, and cooling to produce finished EPS products.

What types of takeaway food boxes can be produced with an EPS making machine?

An EPS making machine can produce a variety of takeaway food boxes, including clamshell containers, trays, cups, bowls, and more. The machine can be equipped with different molds to accommodate various shapes and sizes.

What are the benefits of using EPS for food packaging?

EPS offers several benefits for food packaging, including excellent insulation properties, lightweight construction, durability, moisture resistance, and affordability. It helps keep food fresh and protected during transportation and storage.

Is EPS food packaging recyclable?

Yes, EPS food packaging is recyclable. Many recycling facilities accept EPS foam for recycling, where it can be melted down and reused to make new products. However, it’s essential to check with local recycling guidelines and facilities for specific instructions on recycling EPS foam.

What are the key features to consider when choosing an EPS making machine?

When choosing an EPS making machine, consider factors such as production capacity, customization options, energy efficiency, ease of operation, reliability, safety features, and after-sales support. It’s essential to select a machine that meets your production requirements and budget while ensuring quality and efficiency.

How can I maintain an EPS making machine for optimal performance?

Proper maintenance is essential to ensure optimal performance and longevity of an EPS making machine. Regular cleaning, lubrication, inspection of components, and timely replacement of worn parts are critical maintenance tasks. Additionally, following manufacturer-recommended operating procedures and safety guidelines can help prevent issues and prolong the machine’s lifespan.

Can an EPS making machine be customized to meet specific production needs?

Yes, many EPS making machines offer customization options to meet specific production needs. This may include adjusting parameters such as box size, thickness, design, and production speed to accommodate unique requirements. Customization capabilities can help optimize production efficiency and meet customer demands effectively.