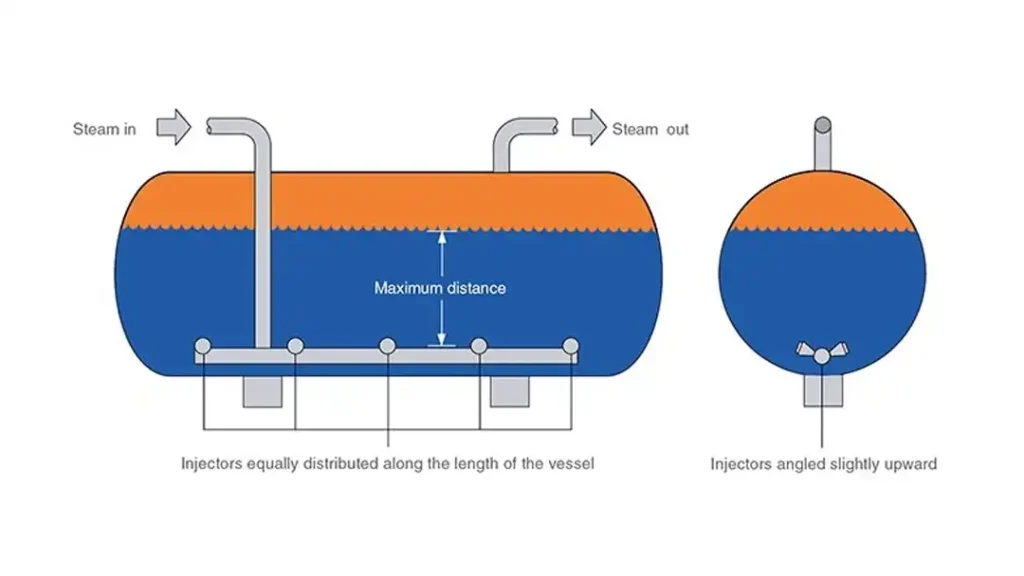

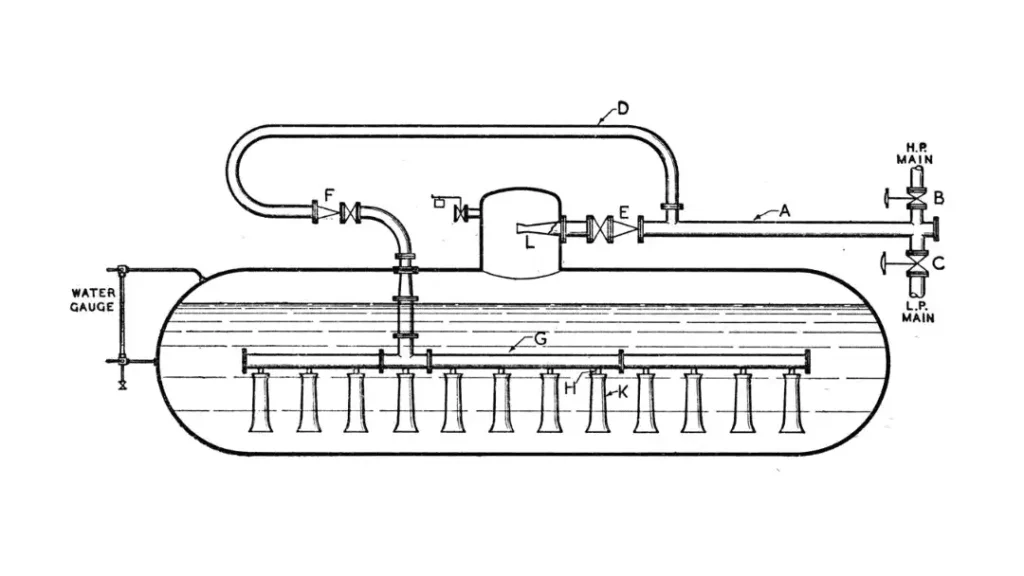

The working principle of a steam accumulator tank involves storing excess steam during periods of low demand and releasing it during periods of high demand. Here’s a step-by-step explanation of how it operates:

Maintaining Pressure: The insulated vessel keeps the water at high pressure and temperature until the steam is needed. The stored energy is in a stable state, with the water holding both sensible heat and latent heat from the condensed steam.

A steam accumulator works by storing energy in the form of high-pressure, high-temperature water during periods of low steam demand and releasing it as steam during periods of high demand. This process helps balance the load on the boiler, improves energy efficiency, and ensures a stable steam supply.

Sizing a steam accumulator involves determining the required capacity to effectively store and release steam based on the specific needs of the steam system. The process considers factors such as steam demand, boiler capacity, and pressure requirements. Here’s a step-by-step guide to sizing a steam accumulator:

Determine Steam Demand:

Assess Boiler Capacity:

Calculate Storage Requirements:

Determine Accumulator Capacity:

Volume Calculation:

Safety and Buffer Capacity:

Let’s consider a simplified example to illustrate the process:

Steam Demand:

Boiler Capacity:

Calculate Storage Requirements:

Accumulator Efficiency:

Volume Calculation:

Safety and Buffer Capacity:

The steam accumulator should have a total volume of approximately 494 m³ to manage the steam load in this example effectively.

We are leading EPS manufacturer to provide all-in-one EPS solutions for your EPS project. Welcome to contact us at any time if you are looking for EPS machine, EPS material and many other EPS related product, please feel free to contact us now to get instant help.

Copyright © 2024 Hangzhou Epsole technologies Co.Ltd.

WhatsApp us