Sealing Ring for EPS Machine

Are you in need of sealing ring in EPS machine? We are the leading EPS manufacturer to provide various EPS machines, also EPS machine accessories. For more sealing ring gasket, please feel free to get samples now.

Our Sealing Rings for EPS machine

Finding the correct seal ring for your EPS machine can be frustrating and time-consuming, especially if you’re dealing with a large inventory. By keeping all your seal rings in one place.

- Reduce Errors: Having all the seal rings together helps prevent accidentally grabbing the wrong one, which can save you from costly mistakes and potential equipment damage.

- Boost Efficiency: When you need a seal ring fast, a central location saves valuable time searching through various places. This gets your machine back up and running sooner.

- Improve Organization: Keeping seal rings consolidated promotes a clean and organized workspace.

Sealing Ring for EPS Filling Gun

Sealing rings are crucial parts of an EPS filling gun, ensuring a tight seal that prevents leaks during the EPS molding process. These rings are typically made from elastomers like nitrile rubber or fluoroelastomer (FKM), which resist wear and tear and can withstand the high temperatures involved in EPS molding.

EPS Filling Gun Pressure Plate Sealing Ring

The EPS filling gun pressure plate sealing ring is a crucial component that creates a tight seal between the pressure plate and the gun body. This prevents leaks of the expanding EPS beads during the molding process.

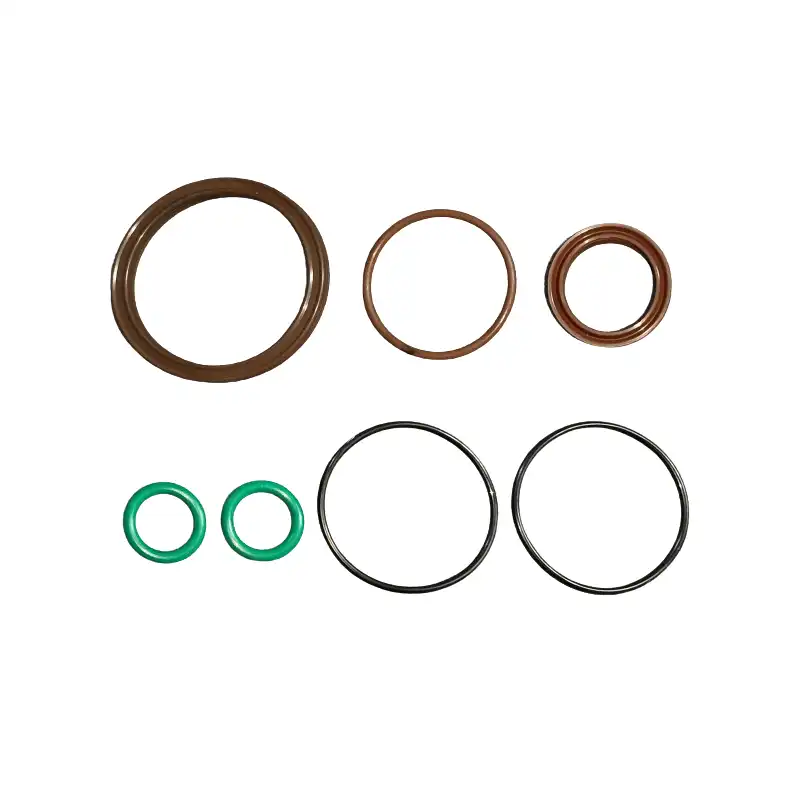

EPS machine sealing ring kit

EPS filling gun sealing ring kits contain a collection of various sealing rings used throughout the gun. These rings ensure a tight seal at different connection points, preventing leaks of the expanding EPS beads during the molding process.

EPS Machine Sealing Ring FAQs

What do EPS machine sealing rings do?

EPS machine sealing rings create tight seals at various connection points within the EPS filling gun. This prevents leaks of the expanding EPS beads during the molding process, ensuring smooth operation and product quality.

What are some common types of EPS machine sealing rings?

- Piston seal: Seals between the piston and cylinder bore.

- Nozzle seal: Seals the nozzle where molten EPS exits the gun.

- Joint seal: Seals connections between the gun body and other components (hose, adapter).

- Pressure plate seal: Creates a tight seal between the pressure plate and the gun body.

What are EPS machine sealing rings typically made of?

They are commonly made from elastomers like nitrile rubber or fluoroelastomer (FKM) due to their ability to withstand high temperatures and resist wear and tear.

How do I choose the right sealing ring for my EPS machine?

- Compatibility: Ensure the ring is compatible with your specific EPS filling gun model. Refer to the user manual or contact the manufacturer for recommendations.

- Material: Choose a material like nitrile rubber or FKM that can handle the temperatures and pressures involved in your EPS molding process.

- Size: Improper size can cause leaks. Ensure you get the correct size for your specific application.

How often should I replace EPS machine sealing rings?

Replacement frequency depends on usage and the manufacturer‘s recommendations. Generally, replace them when you notice leaks or a decrease in molding efficiency.

How can I order an EPS foam cornice machine?

We can customize the premium EPS foam cornice machine to support you produce various types of EPS foam cornice for your building project, and please feel free to contact us at any time.