Lost foam casting is an innovative manufacturing process that uses foam patterns to create complex metal parts with high precision. By replacing traditional molds, it reduces material waste and allows intricate designs that are otherwise difficult to achieve in conventional casting methods.

This guide explores every aspect of Lost Foam Casting, from its process and materials to applications across industries. Whether you’re a manufacturer, engineer, or hobbyist, you’ll gain valuable insights into how this technique can enhance production efficiency, reduce costs, and deliver consistent, high-quality results.

What Is Lost Foam Casting

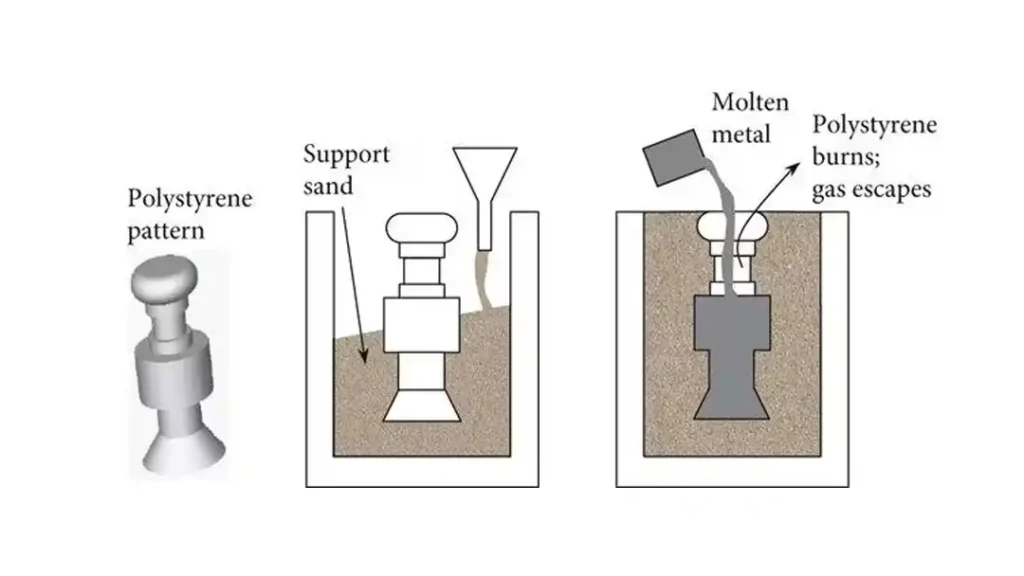

Lost foam casting is a type of evaporative-pattern casting process that utilizes foam patterns to create metal parts. The foam pattern, typically made from polystyrene, is coated with a refractory material and then buried in sand. When molten metal is poured into the mold, the foam vaporizes, leaving behind a cavity that is filled by the metal, thus forming the final cast part.

Origin of Lost-Foam Casting

The origin of lost-foam casting can be traced back to a patent filed by H.F. Shroyer in April 1956. Shroyer proposed a novel idea of embedding foam patterns within green sand to facilitate metal casting.

This inventive approach involved cutting a pattern from expanded polystyrene (EPS) and supporting it with bonded sand throughout the casting process. Shroyer’s innovative technique, which was formally patented in 1958, laid the foundation for what is now known as lost-foam casting, also referred to as the whole-mold technique. This method revolutionized the casting industry by enabling the production of complex and precise metal parts with high efficiency and reduced waste.

Importance of Lost Foam Casting

Lost-foam casting is highly significant in manufacturing due to its ability to produce complex and intricate metal parts with high precision and minimal material waste. This method offers several advantages over traditional casting techniques, making it invaluable for industries that require detailed and high-quality components.

One of the primary benefits of lost-foam casting is its cost-effectiveness. By reducing the need for machining and finishing operations, it lowers production costs and improves overall efficiency. Additionally, the process minimizes defects and ensures tight tolerances, which are crucial for applications in automotive, aerospace, and heavy machinery industries. The versatility and accuracy of lost-foam casting enable manufacturers to create parts with complex geometries that would be difficult or impossible to achieve with other casting methods, thereby enhancing design flexibility and innovation in product development.

Key Principles of Lost Foam Casting

Lost Foam Casting (LFC) is a versatile metal casting process using foam patterns to create precise, complex shapes. The foam is replaced by molten metal, producing accurate, smooth, and detailed castings. Understanding these key principles ensures efficiency, high-quality results, and minimal defects in industrial manufacturing.

Finishing and Inspection: We remove excess sand, perform finishing operations, and inspect each casting for specifications compliance. This step guarantees structural integrity, functional performance, and high-quality results for end-use applications.

Pattern Creation: We craft foam patterns that replicate the final casting shape with precision. Accurate dimensions and intricate details in the foam directly impact casting quality, reducing defects and ensuring high-precision, reliable metal parts for industrial applications.

Mold Filling: We prepare sand molds around the foam pattern for proper compaction and support. During casting, molten metal fills the cavity without disturbing the mold, ensuring complete formation, minimal voids, and superior detail reproduction.

Foam Vaporization: We control foam vaporization when molten metal contacts the pattern to prevent gas pockets and defects. Proper vaporization ensures smooth metal flow, precise feature replication, and defect-free castings with excellent surface quality.

Metal Solidification: We monitor metal cooling to achieve uniform solidification, preventing shrinkage, cracks, or warping. Controlled solidification ensures the casting meets strength, durability, and dimensional accuracy requirements for reliable industrial use.

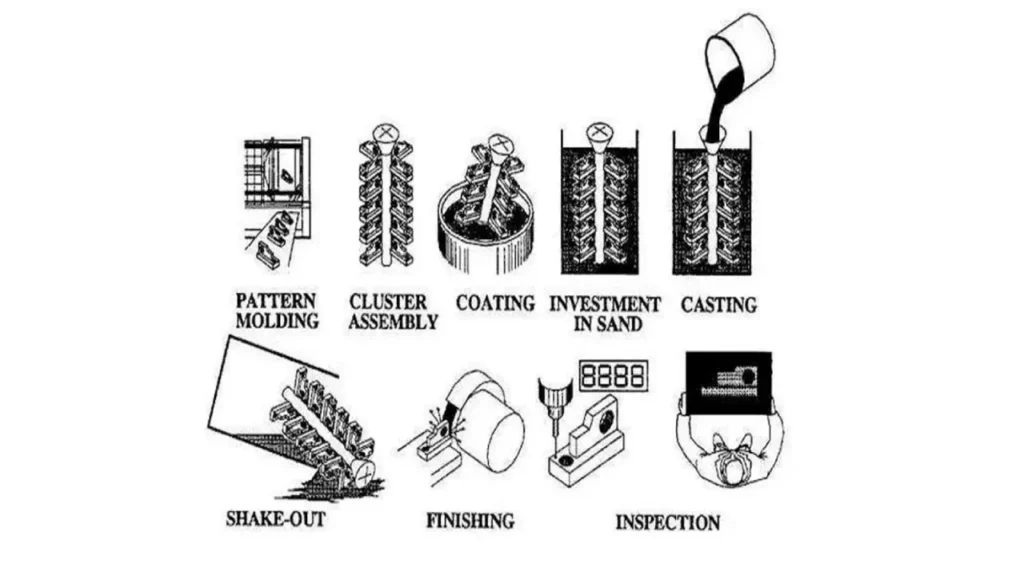

How Lost Foam Casting Works

Lost Foam Casting (LFC) is a precision metal casting process that replaces foam patterns with molten metal to create complex shapes. The foam evaporates upon contact with metal, producing accurate, smooth, and detailed castings.

Understanding each step ensures high-quality results, efficiency, and minimal defects in industrial applications.

- Finishing and Inspection: After solidification, we remove excess sand and perform finishing operations like grinding or machining. Each casting undergoes inspection to ensure compliance with specifications, guaranteeing high-quality, functional parts ready for use in demanding applications.

- Pattern Creation: We start by creating an exact foam replica of the final part. The foam’s dimensions and intricate details are critical, as they determine the casting’s accuracy. Proper pattern design reduces defects and ensures consistent results in every production cycle.

- Mold Preparation: We pack fine sand tightly around the foam pattern to form a stable mold. Proper sand compaction supports the foam and prevents shifting during casting, ensuring the molten metal fills the cavity completely and the final casting maintains precise shape and detail.

- Pouring Molten Metal: We carefully pour molten metal into the mold. The metal flows into the cavity as the foam vaporizes. Controlled pouring ensures smooth metal flow, avoids turbulence, and prevents defects like voids or incomplete filling, resulting in high-quality, defect-free castings.

- Foam Vaporization: As molten metal contacts the foam, it instantly vaporizes, leaving behind a cavity that the metal fills. We manage this process to prevent gas entrapment, ensuring the casting faithfully replicates the foam pattern with excellent surface quality and structural integrity.

- Cooling and Solidification: We allow the metal to cool and solidify gradually. Proper solidification prevents shrinkage, cracking, or warping, ensuring the casting achieves the required mechanical strength, dimensional accuracy, and durability for its intended industrial or commercial application.

What is the Lost Foam Casting Process

Lost Foam Casting is an advanced manufacturing technique that uses foam patterns to create complex metal parts. The foam is replaced by molten metal, which vaporizes it and fills the cavity. This method ensures precision, reduces waste, and allows intricate designs that are difficult to achieve with traditional casting methods.

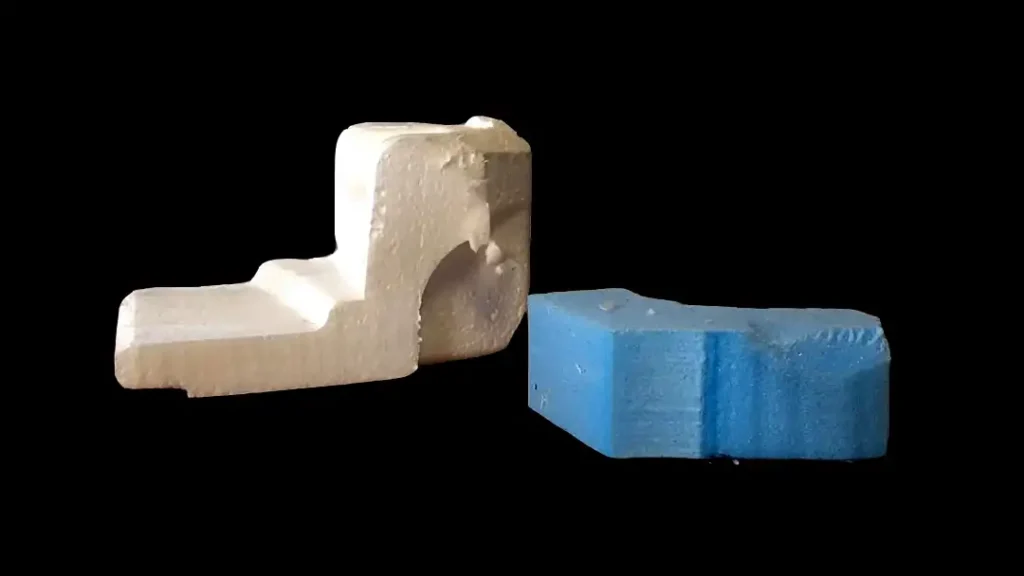

Step 1: Pattern Making

The foam pattern is carefully shaped to match the final metal part. Accuracy in pattern design is essential because any imperfections in the foam directly affect the quality, surface finish, and dimensions of the casting.

We use precision tools and techniques to create foam patterns for complex geometries. This ensures that intricate details, internal cavities, and thin walls are accurately replicated, providing a reliable foundation for the subsequent casting steps and achieving consistent high-quality results.

Step 2: Coating the Pattern

Once the foam pattern is ready, it is coated with a refractory material. This coating protects the foam during metal pouring, prevents defects, and ensures the molten metal flows smoothly around the pattern.

Proper coating thickness and uniform application are crucial. The coating stabilizes the foam, enhances surface finish, and allows the casting to withstand thermal shock from molten metal, ensuring the final product meets dimensional and structural requirements.

Step 3: Mold Filling

The coated foam pattern is placed in a container and surrounded by loose sand. We compact the sand carefully to provide support while allowing gases to escape during the casting process.

This step ensures the foam remains stable and the mold retains its shape. Proper mold filling prevents shifting, supports intricate details, and allows the molten metal to occupy every cavity, resulting in precise and defect-free castings.

Step 4: Pouring Molten Metal

Molten metal is poured over the foam pattern, causing it to vaporize instantly. Controlled pouring ensures the metal fills the mold without turbulence or air entrapment.

This step allows the metal to capture every detail of the foam pattern. Careful temperature management and pouring speed are essential to produce consistent castings with smooth surfaces and excellent structural integrity.

Step 5: Cooling and Finishing

After solidification, the casting is removed from the mold. Excess material is trimmed, and finishing processes such as grinding, polishing, or heat treatment are applied.

Proper finishing ensures dimensional accuracy, enhances surface quality, and improves structural performance. We verify each casting to meet specifications, preparing it for industrial applications and ensuring durability, reliability, and long-term performance.

Applications of Lost Foam Casting

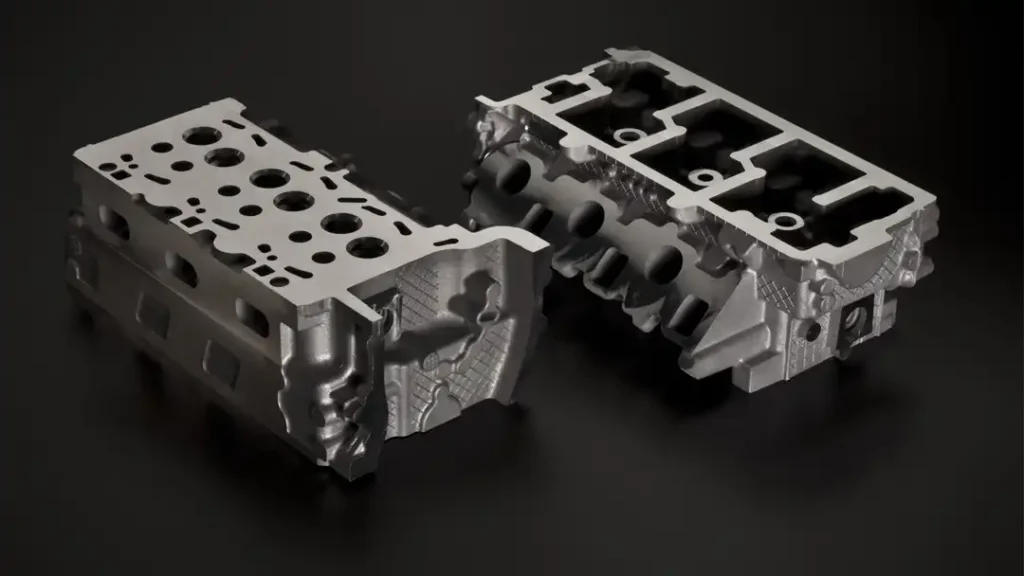

Automotive Industry

In the automotive industry, lost foam casting is used to produce engine blocks, cylinder heads, and other critical components. The process’s precision and ability to produce complex geometries make it ideal for automotive applications.

Aerospace Industry

Lost foam casting is also prominent in the aerospace sector, where it is used to create lightweight and high-strength components for aircraft engines and structural parts. The method’s accuracy and ability to produce parts with intricate details are highly valued.

Heavy Machinery

Heavy machinery manufacturers use lost foam casting to produce large and complex parts such as pump housings, valve bodies, and gearboxes. The process’s efficiency and cost-effectiveness are significant advantages in this industry.

Art and Sculpture

Artists and sculptors utilize lost foam casting to create detailed and intricate metal artworks. The ability to replicate fine details and the flexibility in design make it a preferred method for metal sculptures.

Advantages of Lost Foam Casting

Lost Foam Casting (LFC) offers a modern, efficient method for producing complex metal parts with high precision. By using foam patterns that vaporize upon contact with molten metal, LFC reduces machining, minimizes waste, and produces smooth, detailed castings. Understanding its advantages helps manufacturers optimize production and quality.

Versatility in Materials: LFC works with a wide range of metals, including aluminum, steel, and cast iron. We adapt the process to various alloys, ensuring flexibility and suitability for diverse industrial and commercial applications.

High Dimensional Accuracy: Lost Foam Casting delivers precise dimensions and intricate details, reducing the need for post-casting machining. We ensure that every casting accurately replicates the foam pattern, resulting in consistent, high-quality parts suitable for complex industrial applications.

Complex Geometries: LFC allows the creation of intricate shapes that are difficult or impossible with traditional casting. We can produce internal cavities, thin walls, and undercuts, enabling designers to realize complex designs with minimal limitations.

Reduced Machining and Waste: The process minimizes excess material and machining requirements. By accurately replicating the foam pattern, we reduce scrap, save time, and lower production costs, making LFC an efficient and environmentally friendly casting method.

Smooth Surface Finish: Lost Foam Casting produces castings with smooth surfaces and fine details. We achieve superior finish quality, reducing post-processing requirements and delivering aesthetically and functionally superior parts straight from the mold.

What Are the Metals Used in Lost-Foam Casting

Lost-foam casting utilizes a variety of metals, each chosen for its specific properties and suitability for different applications:

Stainless Steel:

Stainless steel, composed primarily of iron and chromium, is renowned for its exceptional corrosion resistance and strength. It is preferred in applications requiring both durability and aesthetic appeal. During the lost-foam casting process, molten stainless steel is poured into the foam mold, replacing the evaporated foam to form intricate shapes. While stainless steel may be more costly and challenging to work with, its high strength and corrosion resistance make it indispensable in various industries.

Aluminum Alloys:

Aluminum alloys combine aluminum with other elements to achieve a balance of lightweight properties and effective thermal conductivity. In lost-foam casting, these alloys are used where parts require specific strength-to-weight ratios. Their lightweight nature and good thermal properties are advantageous, though they may have limitations in applications requiring extremely high strength. Aluminum alloys are widely utilized across industries for their versatility and performance characteristics.

Nickel Alloys:

Nickel alloys are prominent in lost-foam casting for their exceptional resistance to high temperatures and corrosion. These alloys are favored in extreme environments and specialized applications where robust performance is critical. Nickel alloys offer unique properties but require careful consideration of cost and alloy selection to match specific application needs effectively.

Steels:

Steels encompass a broad range of alloys tailored for specific applications in lost-foam casting. These alloys vary in strength, hardness, and wear resistance, catering to diverse industrial needs. While offering a spectrum of advantageous properties, precise alloy selection is crucial to meet specific application requirements effectively. Steels are extensively used in automotive, aerospace, and machinery sectors for their reliability and mechanical properties.

Cast Irons:

Cast irons, including variations like gray iron and ductile iron, are crucial in lost-foam casting due to their high compressive strength and wear resistance. They excel in heavy-duty applications where durability and toughness are paramount. However, achieving optimal results with cast irons requires meticulous control and consideration during the casting process to manage their unique properties effectively.

Each metal used in lost-foam casting plays a distinct role, offering a combination of mechanical properties, durability, and performance characteristics suited to diverse industrial requirements.

Difference Between Lost-Foam Casting vs Sand Casting

Lost-Foam Casting vs Sand Casting: Lost-Foam Casting (LFC) and Sand Casting (SC) are widely used metal casting techniques. Both create metal parts but differ in process, precision, surface finish, cost, and material suitability, impacting industrial applications significantly.

1. Process

Lost-Foam Casting uses a foam pattern coated with refractory material. The foam evaporates when molten metal is poured, leaving a cavity that forms the final part. This allows for intricate shapes with minimal post-processing.

Sand Casting involves packing sand around a solid pattern to create a mold cavity. After removing the pattern, molten metal is poured into the cavity. The mold must be broken to retrieve the casting, making complex shapes more challenging.

2. Precision and Tolerance

Lost-Foam Casting offers higher dimensional accuracy due to the evaporative pattern, reducing the need for machining. Tolerances can be very tight, making it suitable for detailed components like automotive parts and intricate industrial components.

Sand Casting typically has lower precision because sand molds can shift slightly during pouring. Parts often require additional machining to meet strict dimensional requirements. This method is better for larger components where minor tolerance deviations are acceptable.

3. Surface Finish

Lost-Foam Casting provides smooth surfaces, often reducing or eliminating the need for finishing. The evaporative foam allows metals to flow freely, minimizing defects and surface roughness, ideal for aesthetic or functional applications.

Sand Casting produces rougher surfaces due to the granular nature of the sand. Post-casting processes like grinding, sanding, or polishing are often necessary, especially for applications requiring smooth finishes or tight seals.

4. Cost and Tooling

Lost-Foam Casting requires specialized foam patterns and coatings, which can increase initial costs. However, it reduces labor, machining, and waste, making it cost-effective for medium to high-volume production.

Sand Casting has lower initial tooling costs because patterns and molds are simpler. The process is labor-intensive, with higher scrap rates and additional finishing, making it more cost-effective for small batches or large, simple components.

5. Material and Application Suitability

Lost-Foam Casting is versatile for metals with low to moderate melting points like aluminum, magnesium, and some steels. Its capability to form complex geometries makes it ideal for automotive, aerospace, and intricate industrial parts.

Sand Casting works with almost all metals, including high-melting-point alloys like steel and cast iron. It is suitable for large, heavy components like engine blocks, pumps, and industrial machinery, where high complexity is less critical.

Here are some differences between lost foam casting and sand casting:

| Aspect | Lost-Foam Casting (LFC) | Sand Casting (SC) |

|---|---|---|

| Process | Foam pattern evaporates; metal fills cavity | Sand mold; pattern removed before pouring |

| Precision & Tolerance | High accuracy, minimal machining | Lower accuracy, often needs machining |

| Surface Finish | Smooth, less finishing required | Rough, finishing usually required |

| Cost & Tooling | Higher initial cost, cost-effective for high volume | Lower initial cost, labor-intensive |

| Material & Applications | Low to medium melting metals, complex parts | Wide metal range, suitable for large parts |

Conclusion

Lost Foam Casting offers unmatched versatility and precision, making it ideal for producing complex metal components. Its efficiency and reduced material waste provide significant advantages for manufacturers seeking cost-effective, high-quality solutions. We help you understand how to implement this method effectively for various industrial applications.

By mastering Lost Foam Casting, businesses can achieve consistent results, minimize production errors, and improve overall workflow efficiency. Choosing the right foam patterns, materials, and process parameters ensures optimal performance, enabling manufacturers to meet stringent quality standards while maintaining flexibility in design and production.

For reliable and affordable solutions, get wholesale Lost Foam Casting products from our Epsole. We provide a wide range of molds, foam patterns, and technical support to help you streamline production, improve efficiency, and achieve precise, high-quality castings tailored to your specific needs.