Styrofoam, or polystyrene foam, is a common material. It usually has a light, porous structure. In daily life, Styrofoam has a wide range of applications.

For example, it is often used as a packaging material to protect fragile items such as electronic products and glass products from damage during transportation. In the catering industry, we can see disposable lunch boxes and cups made of Styrofoam. In the construction industry, it may be used for some simple insulation measures.

And it also plays a role in various other fields. In the logistics industry, it is used for filling and cushioning; it may also be used in the production of certain handicrafts.

It is precisely because of these wide applications of Styrofoam that we have to pay attention to its various characteristics, among which insulation performance is a very important point.

Is Styrofoam a Good Insulator?

How will its insulation performance change in different environments and uses? These issues are worth our in-depth discussion and research. By analyzing its insulation performance, we can better understand how to use Styrofoam reasonably and whether there are other better options when pursuing insulation effects.

Styrofoam Characteristics

Styrofoam has the following characteristics:

Physical characteristics

- Low density: It is lightweight, facilitating handling and usage.

- Porous structure: Filled with a large number of tiny bubbles, endowing it with good heat insulation and sound insulation properties.

- Relatively good elasticity: Can buffer pressure and impact to a certain extent.

Chemical characteristics

- Relatively high stability: Generally, it is not prone to violent reactions with other substances.

- Water resistance: Has certain resistance to water.

Other characteristics

- Low cost: This is one of the reasons for its wide application.

- Good processability: Can be relatively easily made into various shapes and specifications.

- Moderate corrosion resistance: But can resist the erosion of common environments to a certain extent. It also has the drawback of being difficult to degrade, which causes certain environmental pollution problems. Moreover, its flammability is also a concern, and special attention needs to be paid to fire safety when using it.

Insulation Performance Test

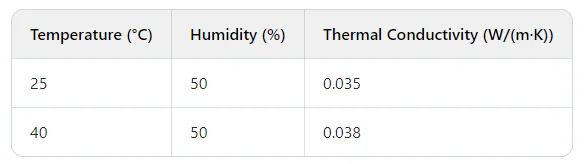

In a series of experiments, the insulation performance of Styrofoam under different conditions was tested. When the temperature was maintained at 25°C and the humidity was 50%, the thermal conductivity of Styrofoam was measured to be 0.035 W/(m·K). As the temperature increased to 40°C, the thermal conductivity slightly rose to 0.038 W/(m·K). However, even at higher temperatures, Styrofoam still showed relatively good insulation.

The following is a simple data table to illustrate:

It can be seen from the data that Styrofoam maintains a certain level of insulation performance in different temperature and humidity environments.

Moreover, in another study, the electrical resistivity of Styrofoam was tested. It was found that at normal room temperature and humidity, the electrical resistivity could reach 10^8 ohm·m, indicating its good electrical insulation property. These experiments and data provide a basis for further understanding the insulation performance of Styrofoam and help us better evaluate its application scenarios and limitations.

Analysis of Styrofoam’s Actual Application Scenarios

In the field of building insulation, Styrofoam is often used as insulation boards on the exterior walls of buildings. It helps to reduce heat transfer, keeping the interior warm in winter and cool in summer. For example, in a construction project, Styrofoam insulation boards were installed to effectively improve the energy efficiency of the building.

In packaging materials, Styrofoam is commonly used to protect delicate items during transportation. It cushions and insulates, preventing damage from impact and temperature changes. When shipping electronics, Styrofoam packaging keeps the devices safe and maintains a stable temperature environment.

In the field of cold chain transportation, Styrofoam containers or boxes are used to maintain low temperatures. The thick Styrofoam walls prevent heat from entering and keep the contents cold for a long time. For instance, in the transport of perishable foods, Styrofoam containers ensure the quality and freshness of the goods.

However, in these applications, Styrofoam also faces some challenges. One challenge is its environmental impact. It is not easily degradable and can cause pollution. There is also a concern about its flammability in some cases, which requires strict fire safety measures. Additionally, as new technologies and materials emerge, there is increasing competition, and Styrofoam needs to continuously improve and innovate to maintain its competitiveness in these fields.

Environmental Impact

Styrofoam, while being an effective insulator, poses significant sustainability concerns. Its non-biodegradable nature means that it persists in the environment for a long time, creating a burden. Landfills are filled with Styrofoam waste that does not decompose easily, taking up space and potentially harming ecosystems.

Moreover, the production and disposal of Styrofoam contribute to environmental pollution. The manufacturing process may release harmful emissions, and its disposal can lead to visual pollution and other negative impacts.

In response to these issues, several eco-friendly alternative solutions are being developed and explored. For instance, natural fiber insulation materials like cellulose or hemp are being investigated. These materials are renewable and biodegradable, offering a more sustainable option. Another alternative is recycled materials, such as recycled plastic or glass, which can be processed to create insulation products. These options not only reduce the environmental impact but also promote a circular economy. However, these alternatives may face challenges in terms of cost, performance, and scalability, but ongoing research and innovation are working towards overcoming these hurdles to make them more viable and widespread.

Conclusion

Now you should have the answer. Is Styrofoam a Good Insulator? Styrofoam exhibits certain excellent insulation performance, which has enabled it to be widely used in various fields. However, it also comes with notable drawbacks, such as its difficult degradation and potential environmental impacts.

It is crucial to comprehensively consider both its advantages and disadvantages. In different scenarios, a careful assessment is needed to select the most appropriate insulating material. While Styrofoam may be suitable in some cases, in others, alternative materials with better environmental profiles might be preferred.

We must also emphasize the significance of paying attention to environmental protection and sustainability. The choice of insulating materials should not only focus on functionality but also take into account their long-term effects on the environment. This calls for continuous research and development of more eco-friendly and sustainable insulation options.

By being aware of these factors and making informed decisions, Epsole’s EPS machines can better balance the need for insulation with the imperative of protecting our planet and ensuring a sustainable future.