Styrofoam, also known as polystyrene, is a versatile material commonly used in crafting, construction, and packaging due to its lightweight and insulating properties. Whether you’re working on a DIY project or need to cut Styrofoam for industrial purposes, mastering the art of cutting it efficiently and accurately is essential. In this comprehensive guide, we will explore various methods, techniques, and tips for cutting Styrofoam like a pro.

How to Cut Styrofoam?

There are many methods for cutting polyethylene foam, such as using a hot wire cutter, utility knife, hand saw, CNC precision cutter, and so on. Depending on the size of the material, its intended use, the desired shape of the cut, and the available tools, one should choose the appropriate cutting method.

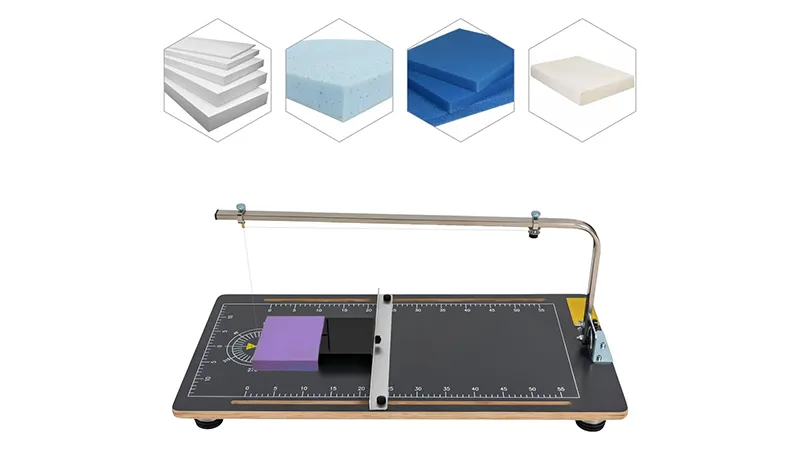

How to Cut Styrofoam Board With a Hot Wire?

Hot wire cutting is one of the most efficient methods for cutting Styrofoam, especially when working with large sheets or blocks. Here’s how to do it:

1. Start by setting up a hot wire foam cutter or DIY hot wire cutter according to the manufacturer’s instructions.

2. Mark the desired cut lines on the Styrofoam surface using a marker or pencil.

3. Turn on the hot wire cutter and allow it to heat up to the desired temperature.

4. Carefully guide the hot wire along the marked cut lines, applying gentle and steady pressure to ensure a smooth cut.

5. Once the cut is complete, turn off the hot wire cutter and allow the Styrofoam to cool before handling it.

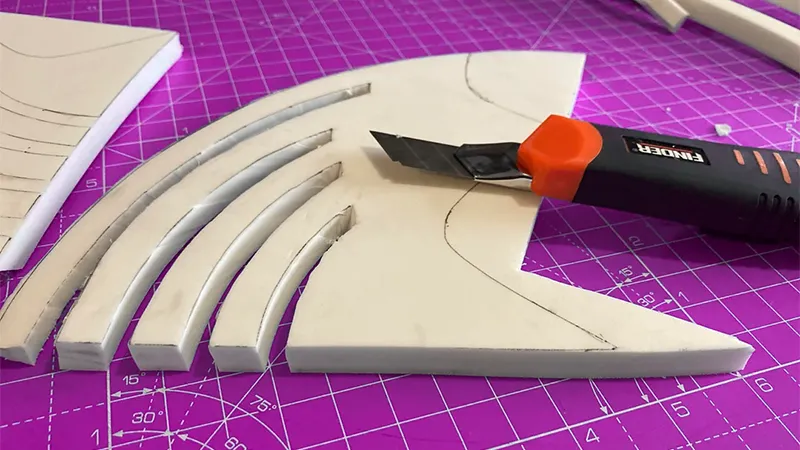

How to Cut Styrofoam Blocks With a Knife?

A utility knife or craft knife is a versatile tool that can be used for cutting Styrofoam with precision. Follow these steps for best results:

1. Choose a sharp utility knife or craft knife with a retractable blade for safety.

2. Place the Styrofoam sheet or block on a flat surface and secure it with clamps or weights to prevent movement.

3. Use a straight edge or ruler to guide the knife along the marked cut lines, applying even pressure to score the surface.

4. Repeat the scoring process multiple times, gradually increasing the depth of the cut with each pass.

5. Once the desired depth is reached, carefully snap the Styrofoam along the scored line to complete the cut.

6. Use sandpaper or a sanding block to smooth out any rough edges or imperfections.

How to Cut Styrofoam at Home With a Sawing

Sawing is another effective method for cutting Styrofoam, particularly when working with thicker materials. Here’s how to do it safely:

1. Choose a fine-toothed saw, such as a coping saw or serrated knife, for cutting Styrofoam.

2. Secure the Styrofoam sheet or block on a stable surface using clamps or a vise to prevent it from moving during the cutting process.

3. Carefully guide the saw along the marked cut lines, using slow and steady strokes to avoid causing damage to the material.

4. For curved cuts or intricate shapes, consider using a scroll saw or jigsaw with a fine-toothed blade for greater precision.

5. Once the cut is complete, use sandpaper or a sanding block to refine the edges and achieve a smooth finish.

How to Cut Styrofoam Without a Hot Wire?

Hot knife cutting is similar to hot wire cutting but involves using a heated blade instead of a wire. Follow these steps for successful hot knife cutting:

1. Heat up a knife blade using a heat gun or propane torch until it reaches the desired temperature.

2. Mark the cut lines on the Styrofoam surface using a marker or pencil.

3. Carefully guide the hot knife along the marked cut lines, applying even pressure to ensure a clean and precise cut.

4. For thicker Styrofoam materials, make multiple passes with the hot knife to achieve the desired depth of cut.

5. Once the cut is complete, allow the Styrofoam to cool before handling it to avoid burns or injuries.

How to Cut Styrofoam Cleanly With CNC Cutting Machine

For professional or industrial applications requiring precision cutting, CNC (Computer Numerical Control) machines offer a highly accurate and efficient solution. Here’s how CNC cutting works:

1. Design the desired cut patterns or shapes using CAD (Computer-Aided Design) software.

2. Upload the design files to the CNC machine and set the parameters for cutting, including depth, speed, and tool selection.

3. Secure the Styrofoam material on the CNC machine bed using clamps or vacuum suction to ensure stability during cutting.

4. Initiate the cutting process, allowing the CNC machine to follow the programmed instructions and execute the cuts with precision.

5. Once the cutting is complete, remove the finished parts from the CNC machine and inspect them for quality and accuracy.

Safety Precautions

Safety should always be a top priority when working with any cutting tools or materials. Before you begin cutting Styrofoam, make sure to take the following safety precautions:

- Wear appropriate protective gear, including safety goggles, gloves, and a dust mask, to protect yourself from airborne particles and potential hazards.

- Work in a well-ventilated area to minimize exposure to fumes and dust generated during the cutting process.

- Keep cutting tools out of reach of children and pets to prevent accidents.

- Familiarize yourself with the operation of cutting tools and follow manufacturer’s instructions carefully to avoid injuries.

Tips for Cutting Styrofoam Like a Pro

In addition to the specific cutting methods mentioned above, here are some additional tips and techniques to help you achieve professional results when cutting Styrofoam:

- Choose the Right Blade: Selecting the appropriate blade for your cutting tool is crucial for achieving clean and precise cuts. For example, a sharp blade with fine teeth is ideal for cutting thin Styrofoam sheets, while a serrated blade may be more suitable for thicker materials.

- Practice Patience: Cutting Styrofoam requires patience and precision, especially when working on intricate designs or detailed cuts. Take your time and avoid rushing the process to minimize the risk of mistakes or errors.

- Use Guides and Templates: Utilize straight edges, rulers, templates, or stencils to guide your cuts and ensure accuracy. This is particularly helpful for achieving straight lines, angles, or repetitive shapes with consistency.

- Experiment with Different Techniques: Don’t be afraid to experiment with various cutting techniques and tools to find the method that works best for your specific project and preferences. Each method has its advantages and limitations, so it’s essential to explore your options and adapt as needed.

- Practice Safety First: Always prioritize safety when cutting Styrofoam, especially when using hot wire cutters, knives, or power tools. Wear appropriate protective gear, work in a well-ventilated area, and follow safety guidelines to prevent accidents or injuries.

FAQ

How to Cut Styrofoam Insulation

To cut Styrofoam insulation, you can use a utility knife, hot wire cutter, or a fine-toothed saw. Start by marking the desired cut lines on the Styrofoam. Use a straight edge to guide your cuts and make multiple passes with the knife to achieve a clean cut. If using a hot wire cutter, allow the wire to heat up and then carefully guide it along the marked lines.

How do I cut a perfect circle in Styrofoam?

Cutting Styrofoam with a battery involves using a battery-powered hot wire cutter. These devices use the battery to heat the wire, which then melts through the Styrofoam. To use, simply turn on the hot wire cutter, allow the wire to heat up, and guide it along your marked lines. This method is effective for detailed and precise cuts.

How do I cut letters from Styrofoam?

Cutting letters from Styrofoam can be done using a hot wire cutter or a sharp craft knife. Start by printing out the letters in the desired font and size, then trace them onto the Styrofoam. Carefully cut along the traced lines with your chosen tool, making sure to go slowly to achieve clean edges. Sand any rough spots with fine sandpaper for a polished finish.

How do I cut thick Styrofoam board?

To cut thick Styrofoam board, a hot wire cutter or a fine-toothed saw is recommended. Secure the Styrofoam on a stable surface to prevent movement. For straight cuts, a hot wire cutter will provide a smooth finish. For more intricate cuts, a fine-toothed saw, such as a coping saw, can be used. Cut slowly and steadily to avoid breaking the Styrofoam.

How do I cut rigid Styrofoam insulation?

Rigid Styrofoam insulation can be cut using a utility knife or a saw. For straight cuts, score the surface of the Styrofoam with the knife, then snap it along the scored line. For thicker or more complex cuts, a fine-toothed saw or a hot wire cutter can be used. Ensure the Styrofoam is securely held in place while cutting to maintain accuracy.

How do I cut Styrofoam for DIY projects?

For DIY projects, Styrofoam can be cut using a variety of tools such as utility knives, hot wire cutters, and saws. Choose the tool based on the thickness and complexity of the cut. Mark your cutting lines, secure the Styrofoam, and proceed with careful, steady cuts. Practice on scrap pieces if you are new to cutting Styrofoam.

How do I cut Styrofoam for a Christmas village?

To cut Styrofoam for a Christmas village, use a craft knife or hot wire cutter for detailed shapes. Begin by drawing your designs on the Styrofoam. Carefully follow the lines with your cutting tool, taking your time to ensure precision. You can create buildings, landscape features, and other elements by combining different cutting techniques.

Conclusion

Mastering the art of cutting Styrofoam requires a combination of skill, knowledge, and practice. By understanding the properties of Styrofoam, choosing the right cutting methods and tools, and following safety precautions, you can achieve professional results and bring your creative projects to life.

Whether you’re a DIY enthusiast, a professional craftsman, or an industrial worker, the tips and techniques outlined in this comprehensive guide will help you cut Styrofoam with precision and confidence.

-300x300.webp)