Understanding how much ICF blocks cost is essential for anyone planning an energy-efficient and long-lasting building project. Prices vary based on brand, material quality, block design, and regional availability. In this guide, you’ll learn what affects ICF block pricing and how to estimate your project budget accurately.

ICF blocks offer excellent insulation, reduced labor needs, and strong structural performance, making them a smart investment for modern construction. By exploring factors like shipping, wall thickness, and project scale, you can make informed decisions and compare suppliers more effectively. This guide ensures you get the best value for your building needs.

What are ICF Blocks?

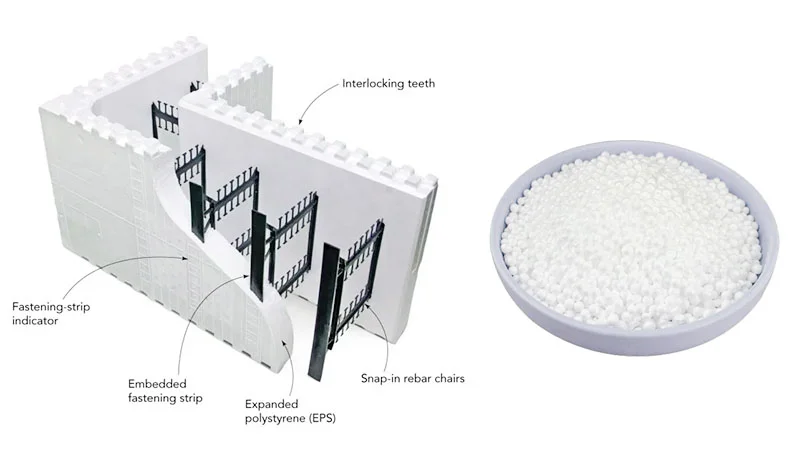

Insulated Concrete Form (ICF) blocks are hollow, interlocking modular units made from expanded polystyrene (EPS) or similar insulating materials. They are designed to stack like building blocks, creating a formwork system that stays in place permanently. Once assembled, the hollow centers are filled with reinforced concrete, forming a strong, insulated, and airtight structural wall.

ICF blocks are widely used in residential and commercial construction because they combine insulation, formwork, and structural support into one system. This results in buildings that are energy-efficient, durable, and resistant to natural disasters. Their ease of installation, noise reduction, and long-term performance make them a popular choice for modern, sustainable building projects.

How Much Are ICF Blocks?

How much ICF blocks cost depends on the brand, block type, project size, and local labor rates, but homeowners often find them more affordable than expected when considering long-term value.

Understanding the price per block, per square foot, and overall installation costs helps you plan your budget clearly. This guide breaks down ICF block pricing so you know what to expect before building.

ICF Blocks Cost Per Square Foot

ICF block cost per square foot varies based on block brand, wall thickness, and project complexity. Most homeowners pay within a predictable range, making it easier to budget for energy-efficient construction. Understanding material, labor, and additional accessory costs helps you estimate your total investment more accurately before starting your build.

Finishing Cost Per Sq Ft

Exterior and interior finishes also affect the total cost. ICF walls accept many finish types, but some may require specialized prep or coatings. Considering finishing materials early helps you estimate a realistic per-square-foot price for the entire wall system.

Material Cost Per Sq Ft

Material prices typically fall within a steady range depending on the manufacturer and R-value you choose. Higher-performance blocks cost slightly more but offer better long-term energy savings. This material portion usually represents the foundation of your overall per-square-foot investment for ICF walls.

Labor Cost Per Sq Ft

Labor charges vary based on installer experience and local construction rates. Skilled crews may cost more upfront but reduce waste and delays. Labor often represents a significant portion of the project cost, especially for homes with complex layouts or multiple stories.

Concrete and Rebar Cost

Filling ICF blocks requires concrete and reinforcement, which add to the per-square-foot cost. The amount of concrete depends on block size and pour thickness. Rebar placement ensures structural strength and contributes to the final cost depending on spacing requirements.

Accessory and Bracing Cost

Bracing systems, connectors, fasteners, and alignment tools are needed to support the walls during installation. These accessories can slightly increase your total cost per square foot. Proper bracing ensures straight, stable walls and reduces risk of installation errors.

Material Cost :

The primary cost component of ICF blocks is the materials themselves. The price per square foot varies depending on the type and brand of blocks chosen. Additionally, factors such as block thickness and insulation R-value can impact the overall material costs.

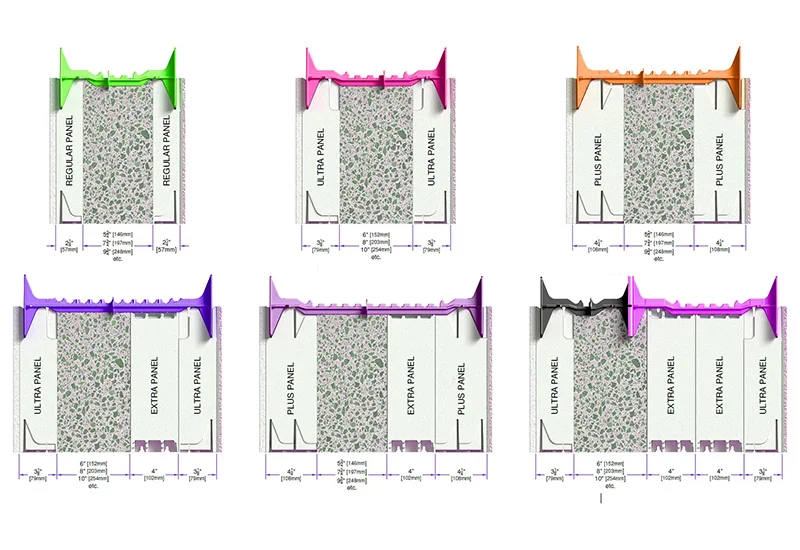

ICF (Insulated Concrete Form) blocks come in various thicknesses, typically ranging from 4 inches to 12 inches.

As for the insulation R-value, it also varies depending on the thickness and type of foam used in the ICF blocks. Generally, ICF blocks offer high levels of insulation due to the foam material they are made from. The R-value typically ranges from around R-17 to R-30 per inch of thickness for EPS foam.

ICF Blocks Total Project Cost Estimation

Estimating the total cost of an ICF block project involves combining material, labor, concrete, and finishing expenses. Project size, wall height, and design complexity all influence the final budget. Careful planning ensures no hidden costs and helps homeowners or contractors predict the investment required for energy-efficient, durable construction.

Labor Cost :

The cost of labor for installing the ICF blocks. This can vary depending on the complexity of the project and the local labor rates.

Labor costs associated with installing ICF blocks include skilled labor for assembly, concrete pouring, and finishing. The complexity of the design and the experience level of the construction crew can influence labor expenses significantly.

Transportation Cost :

The cost of transporting the ICF blocks to the construction site. This can vary depending on the distance to the supplier and any additional delivery fees.

Geographical location plays a significant role in determining ICF block costs due to variations in material availability, labor rates, and building code requirements. Urban areas with higher living expenses may incur higher construction costs compared to rural regions.

Site Preparation:

Preparing the construction site for ICF installation involves excavation, site grading, and foundation preparation.

There may be additional costs associated with ICF construction, such as waterproofing, finishing, and any specialized equipment needed for installation.

Additional Features:

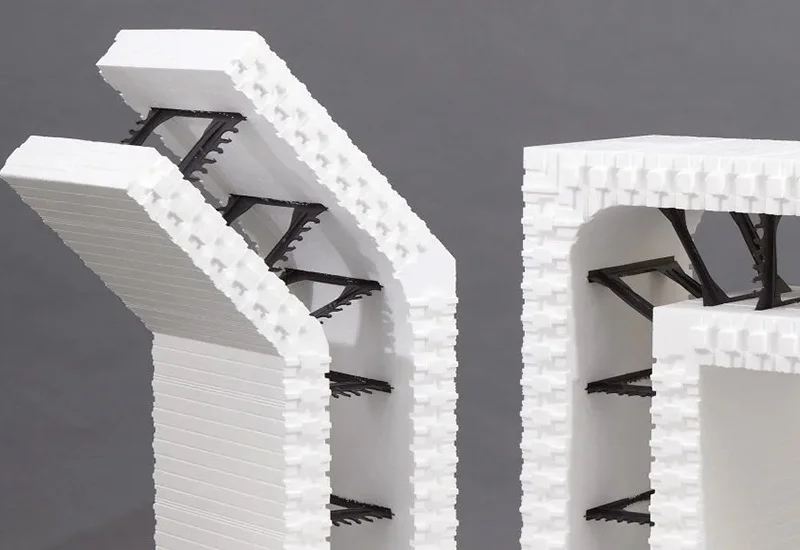

Additional features such as window and door openings, corner configurations, and special architectural details can affect the complexity of the ICF installation process, thereby influencing costs.

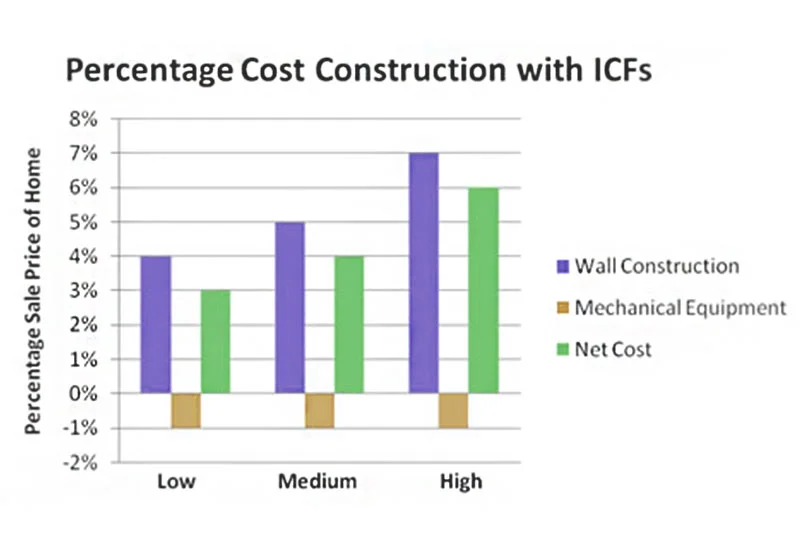

ICF Blocks Cost Comparison with Traditional Building Methods

ICF blocks offer a modern alternative to traditional building methods, often providing long-term savings despite higher initial costs. Comparing ICF to conventional wood frame or concrete block construction highlights differences in material, labor, energy efficiency, and durability. Understanding these aspects helps homeowners and builders make informed choices for their projects.

Material Costs

ICF blocks generally cost more per unit than standard wood or concrete blocks, but they combine insulation and structure in one product. This reduces the need for additional materials like foam panels or extra framing. The upfront expense can be offset by fewer materials required overall.

Traditional materials such as wood or CMU blocks are cheaper initially, but require separate insulation and finishes. Over time, these added costs can make the total expenditure higher compared to ICF walls. Material selection significantly impacts both short-term and long-term project budgets.

Labor Costs

Installing ICF blocks is often faster and simpler than traditional methods because the blocks interlock and require fewer steps. This efficiency can reduce labor costs, especially on larger projects. Experienced crews can complete walls quickly while maintaining structural integrity.

In contrast, wood framing and conventional masonry involve more detailed processes, like measuring, cutting, and applying separate insulation. Labor for these methods can take longer, raising total project costs. Skilled labor shortages may also increase expenses for traditional construction.

Energy Efficiency

ICF walls provide built-in insulation, which reduces heating and cooling costs. The continuous insulation layer and airtight construction significantly improve energy efficiency, creating long-term savings for homeowners. Over a building’s life, this can offset higher initial construction costs.

Traditional construction often requires added insulation layers to achieve similar energy efficiency. Gaps, thermal bridging, or poor installation can reduce performance, resulting in higher utility bills over time. ICF walls often outperform these conventional methods in energy savings.

Durability and Maintenance

ICF walls are highly resistant to fire, pests, and extreme weather, requiring minimal maintenance. Their long lifespan reduces repair costs and ensures structural stability over decades. This durability contributes to cost-effectiveness over the building’s lifetime.

Wood or standard concrete block structures may require frequent maintenance or repairs due to rot, termites, or weathering. These ongoing costs can add up, making traditional methods potentially more expensive in the long run compared to ICF construction.

Construction Speed

ICF block construction is often faster because blocks are lightweight, easy to handle, and require fewer separate steps. Faster construction reduces labor time and allows earlier occupancy, saving money on interim expenses.

Traditional building methods, especially wood framing or masonry, can take longer due to multiple phases like framing, insulation, and finishing. Longer construction periods can increase labor costs and delay project completion, affecting the overall budget.

| Aspect | ICF Blocks | Traditional Methods |

|---|---|---|

| Material Cost | Higher per unit, includes insulation | Lower per unit, requires separate insulation |

| Labor Cost | Faster installation, lower total labor | Slower, more detailed work, higher labor |

| Energy Efficiency | Excellent, built-in insulation | Requires added insulation, potential thermal bridging |

| Durability & Maintenance | Highly durable, minimal upkeep | May require repairs and maintenance |

| Construction Speed | Faster overall construction | Longer construction timeline |

Tips for Cost-Effective ICF Construction

Building with ICF blocks can save money long-term, but careful planning helps control upfront costs. Choosing the right materials, optimizing labor, and minimizing waste are key. Understanding how to balance quality, efficiency, and budget ensures your energy-efficient construction project stays cost-effective from start to finish.

Consider Energy Savings Early: ICF walls offer long-term energy savings, which can offset higher initial costs. Planning insulation, window placement, and passive design strategies maximizes efficiency, helping evaluate the true cost-effectiveness compared to traditional construction methods.

Plan Your Design Efficiently: Simplifying wall layouts and reducing unnecessary corners or curves can lower material usage and labor time. A well-thought-out design minimizes cutting, fitting, and waste, ensuring the project proceeds smoothly while saving both money and construction time.

Buy in Bulk: Purchasing ICF blocks and accessories in bulk often reduces the per-unit cost. Suppliers may offer discounts for larger orders, helping you stay within budget and ensuring enough material on-site to prevent costly delays.

Use Experienced Labor: Skilled ICF installers can complete walls faster and with fewer mistakes. Experienced crews reduce waste, avoid rework, and maintain proper alignment. Investing in experienced labor may cost more upfront but lowers overall project expenses.

Optimize Concrete and Rebar Usage: Calculating concrete volume and rebar requirements accurately prevents over-ordering or under-ordering. Proper estimation reduces material waste and ensures structural safety, controlling costs while maintaining ICF wall strength and durability.

Benefits of Using ICF Blocks

Insulated Concrete Form (ICF) blocks provide a combination of strength, insulation, and ease of construction. They offer long-term savings, energy efficiency, and durability that traditional building materials often cannot match. Understanding their benefits helps homeowners and builders choose ICF for safe, sustainable, and cost-effective construction projects.

Design Flexibility: ICF blocks can be used for a variety of architectural styles and wall shapes. They accommodate curves, openings, and multi-story construction without compromising insulation or strength. This versatility allows for creative and customized building designs.

Energy Efficiency: ICF blocks have built-in insulation that reduces heating and cooling costs. Continuous insulation and airtight construction minimize energy loss, creating a comfortable indoor environment year-round. Over time, this results in significant utility savings and a smaller environmental footprint.

Durability and Strength: ICF walls are highly resistant to fire, pests, and extreme weather. The reinforced concrete core provides structural stability, ensuring long-lasting performance. This strength reduces maintenance needs and enhances the safety and longevity of any building.

Sound Insulation: ICF walls absorb and block sound effectively, creating quieter indoor spaces. This is especially beneficial for homes in noisy areas or commercial buildings. Superior acoustic performance improves comfort and privacy, making ICF a preferred choice for both residential and commercial projects.

Ease of Construction: ICF blocks interlock and are easy to handle, speeding up the building process. Less labor-intensive installation reduces construction time and minimizes errors. This efficiency helps keep projects on schedule while maintaining results.

Are ICF Blocks Expensive?

ICF blocks may have a higher initial cost compared to traditional building materials, but their long-term benefits often outweigh the upfront investment.

What Determines the Cost of ICF Blocks?

Several factors influence the cost of ICF blocks, including market demand, geographic location, block thickness, design complexity, and additional features.

Can I Save Money by Using ICF Blocks?

While the initial cost of ICF blocks may be higher, their energy-saving properties can result in significant long-term savings on heating and cooling expenses.

Are ICF Blocks Worth the Investment?

Yes, ICF blocks offer numerous benefits such as energy efficiency, durability, and disaster resistance, making them a worthwhile investment for both residential and commercial construction projects.

How Do I Calculate the Cost of ICF Blocks for My Project?

To estimate the cost of ICF blocks for your project, multiply the average price per square foot by the total square footage of wall space required.

Are There Financing Options Available for ICF Construction?

Yes, many financial institutions offer loans and mortgages tailored to energy-efficient construction projects, including those using ICF blocks.

Conclusion

Choosing the right ICF blocks begins with understanding pricing, performance, and quality differences among suppliers. By reviewing the main cost factors and comparing options, builders and homeowners can plan with confidence and avoid unexpected expenses during construction. Knowledge ensures smarter decisions and stronger results in any project.

ICF blocks are more than just a building component—they deliver long-term energy savings, structural strength, and comfort. While upfront costs may vary, the long-term benefits often outweigh the price. Evaluating material density, form type, and shipping costs helps you get the best return on investment for your building goals.

For the best value, partnering with a dependable supplier is key. If you’re seeking high-quality ICF blocks at wholesale pricing, Epsole offers reliable products, competitive rates, and industry expertise. Choosing Epsole ensures you get durable, efficient, and cost-effective ICF blocks for any construction project.