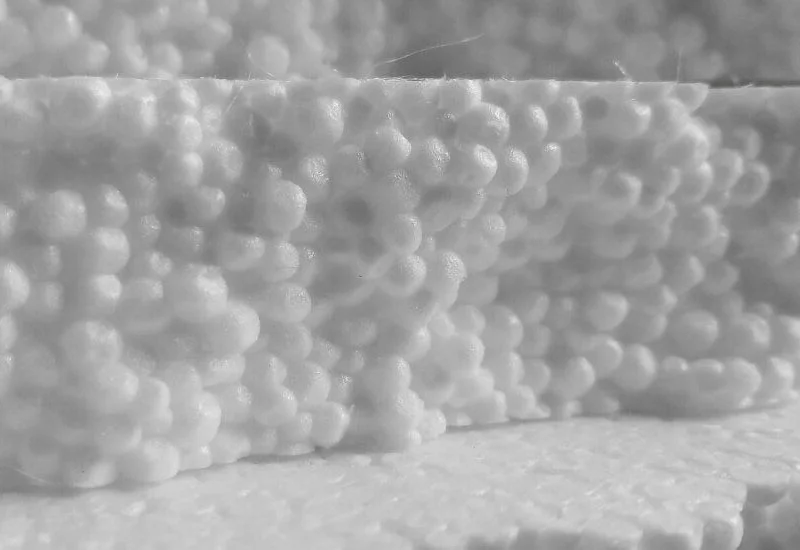

Styrofoam, officially known as expanded polystyrene (EPS), is a ubiquitous material in modern life, from coffee cups to packaging peanuts. Its lightweight and insulating properties make it incredibly versatile. However, its widespread use comes with a significant environmental cost.

A critical question arises: how long does Styrofoam truly last once it’s discarded? Unlike organic materials, Styrofoam is not biodegradable, meaning it doesn’t break down naturally in the environment. This poses a serious challenge for waste management and our planet’s future.

What is Styrofoam?

To understand how long does it take for styrofoam to decompose, first understand Styrofoam.

Styrofoam is a brand name for a type of expanded polystyrene (EPS) foam.

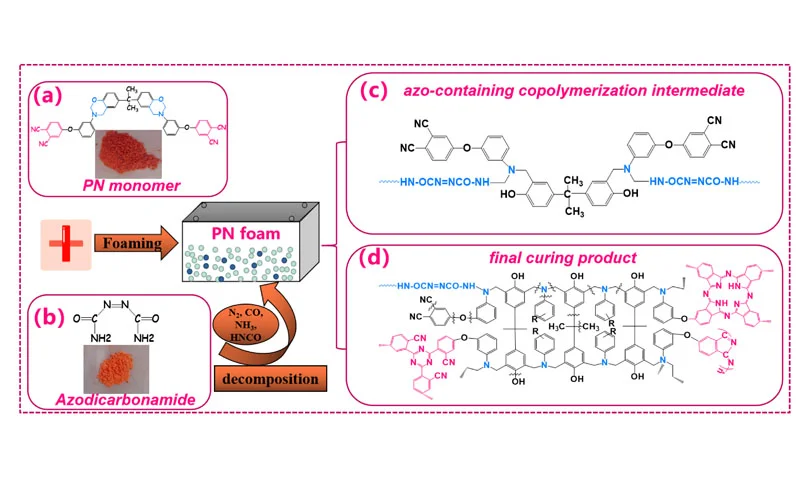

Composed primarily of polystyrene, a petroleum-based plastic, Styrofoam is known for its lightweight, insulating properties. Developed in the 1940s by Dow Chemical Company, it has since become ubiquitous in packaging, construction, and various consumer products due to its versatility and cost-effectiveness.

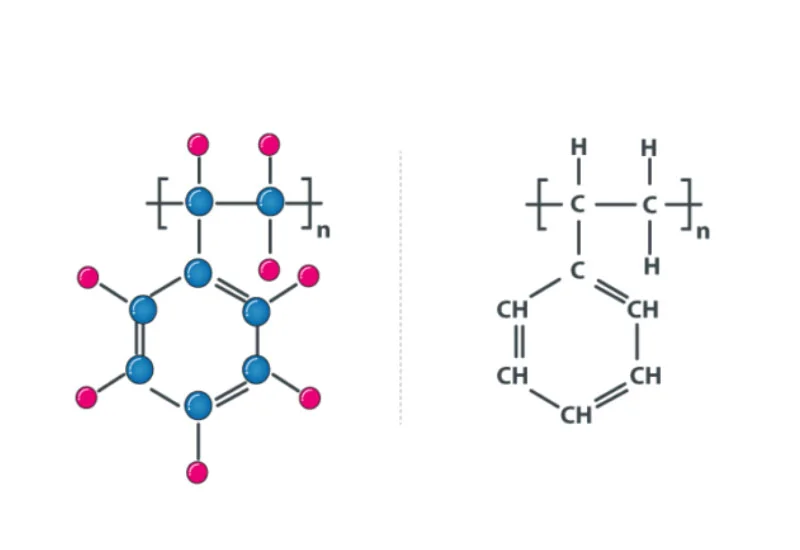

Composition of Styrofoam

Chemical Structure of Styrofoam

Styrofoam, a common term for expanded polystyrene (EPS), is primarily composed of:

- Additives (optional): Depending on the intended use, various chemical additives like flame retardants, colorants, and stabilizers may be included to enhance specific properties.

- Polystyrene: This is the main plastic component, a synthetic polymer derived from styrene monomers. Styrene itself is a petroleum-based product.

- Blowing Agent: A gas, typically pentane, is incorporated during manufacturing. When heated, this agent expands, creating the tiny air pockets that give Styrofoam its lightweight, foamed structure (approximately 98% air).

Does Styrofoam Decompose?

Styrofoam (expanded polystyrene) does not decompose or biodegrade in any meaningful timeframe. It is a synthetic polymer that is highly resistant to natural breakdown by microorganisms.

Instead of decomposing, Styrofoam slowly fragments into smaller and smaller pieces over hundreds of years, eventually becoming microplastics. These tiny particles persist in the environment, polluting soil and water, and are often ingested by wildlife, which can have fatal consequences.

Why Doesn’t Styrofoam Decompose?

Styrofoam’s resistance to decomposition is due to its unique chemical and physical structure. As a synthetic polymer, polystyrene is made up of long, stable hydrocarbon chains that are very difficult for natural microorganisms to break apart. Unlike organic materials, which are food for bacteria and fungi, polystyrene’s molecular structure lacks the chemical bonds that these decomposers can easily target and digest.

- Physical Structure: The foam structure of Styrofoam is 95% air. While this makes it lightweight and excellent for insulation, it also makes it physically resistant to breakdown. The material’s rigidity and compact nature further hinder the ability of environmental factors to cause significant degradation.

- Stable Chemical Bonds: The long polymer chains of polystyrene are held together by strong carbon-carbon bonds, which microorganisms lack the specific enzymes to break down. This chemical stability is what allows the material to persist in the environment for centuries.

- Lack of Nutrients: Styrofoam is composed solely of carbon and hydrogen. It contains no nitrogen or other essential nutrients that would make it a viable food source for most bacteria or fungi, which are the primary agents of natural decomposition.

How Long Does It Take for Styrofoam to Decompose

Styrofoam is notoriously persistent in the environment due to its non-biodegradable nature. Unlike organic materials, it does not decompose through natural biological processes involving microorganisms. Instead, it undergoes a process called photodegradation, where exposure to ultraviolet (UV) light from the sun causes it to break down into smaller and smaller pieces. However, this isn’t true decomposition; the material merely fragments, creating microplastics that remain in the environment for an exceptionally long time.

Estimates for how long Styrofoam takes to “decompose” (or more accurately, physically break down into tiny fragments) vary, but they consistently point to hundreds, if not thousands, of years.

How many years for styrofoam to decompose?

- Microplastic persistence: Even after breaking into microplastics, these tiny particles continue to exist in the environment, posing risks to wildlife and potentially entering the human food chain.

- 500 years or more: Many sources suggest that Styrofoam can take at least 500 years to break down.

- Even longer in landfills: When buried in landfills, Styrofoam is shielded from sunlight and other environmental factors that could contribute to its fragmentation, meaning it can persist for even longer periods, potentially indefinitely, in its original form.

Styrofoam Decomposition Rate

Styrofoam, a brand name for expanded polystyrene (EPS), is a notoriously persistent material with an extremely slow “decomposition” rate. Because it is a synthetic, non-biodegradable polymer, it does not break down through natural biological processes. Instead, it slowly fragments into smaller and smaller pieces over hundreds of years. The rate of this fragmentation is dependent on environmental factors like sunlight and temperature.

Microplastic Persistence: Even after breaking down, the material does not disappear. It becomes microplastics, which are tiny plastic fragments that remain in the environment, polluting ecosystems, and posing a long-term threat to wildlife and human health.

Non-Biodegradable Nature: Styrofoam is chemically stable, and microorganisms lack the necessary enzymes to break down its polymer chains. This means it doesn’t “decompose” in the way that organic waste does.

Photodegradation: The primary way Styrofoam breaks down is through photodegradation, a process where UV radiation from sunlight slowly makes the material brittle and causes it to crumble into tiny pieces. This process can take over 500 years.

The Process of Styrofoam Decomposition

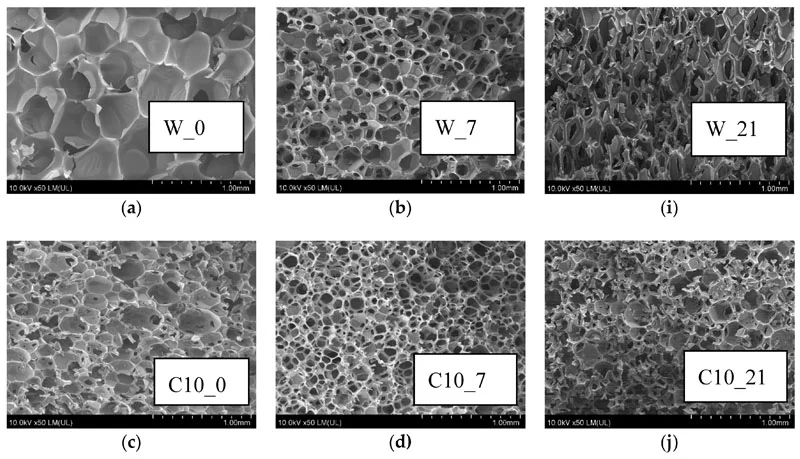

Styrofoam, or expanded polystyrene (EPS), decomposes very slowly due to its chemical and physical properties. The decomposition process involves several stages and mechanisms, primarily physical breakdown and chemical degradation, with minimal biological involvement. Here’s a detailed look at these processes:

Mechanical Forces: Wind, water, and physical abrasion can break Styrofoam into smaller pieces over time. This process is purely physical and doesn’t chemically alter the material.

Microplastics: Over time, these smaller pieces can become microplastics, which are tiny particles that persist in the environment and pose significant ecological risks.

Photodegradation:

UV Radiation: Exposure to ultraviolet (UV) light from the sun causes the surface of Styrofoam to become brittle and break down into smaller pieces. This process, known as photodegradation, involves the breaking of chemical bonds in the polymer due to UV exposure. However, photodegradation is a very slow process and only affects the surface layer exposed to sunlight.

Chemical Degradation

Oxidation:

Exposure to Oxygen: Over long periods, oxygen can cause the polymer chains in Styrofoam to oxidize, leading to the breakdown of these chains into smaller molecules. This process is extremely slow and not significant in most natural environments.

Thermal Decomposition:

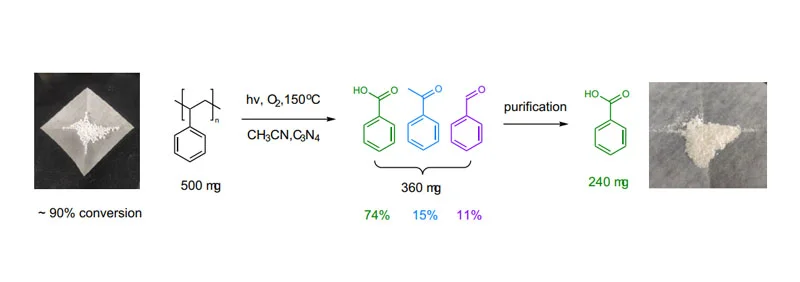

High Temperatures: At high temperatures, such as those found in industrial processes, Styrofoam can undergo thermal decomposition, breaking down into its constituent monomers and other byproducts. This is not a natural process and requires controlled conditions.

Biological Degradation

Microbial Degradation:

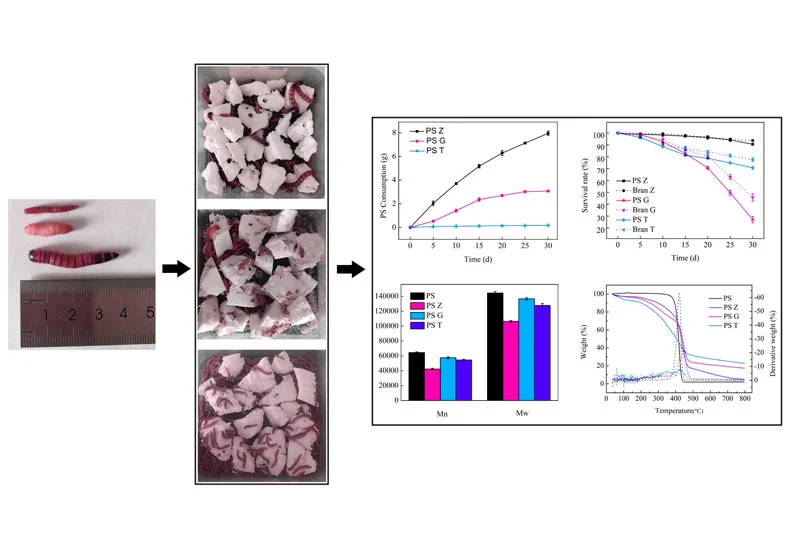

Bacteria and Fungi: Certain bacteria and fungi have been found to have the potential to degrade polystyrene, but this process is very limited and slow. For example, some strains of the bacterium Pseudomonas putida can break down styrene, a monomer of polystyrene. However, the degradation rate is minimal and ineffective on a large scale.

Research on Enzymes: Scientists investigate specific enzymes that can break down polystyrene. While promising, this research is still in its early stages, and practical applications for large-scale decomposition are not yet available.

How to Decompose Styrofoam?

The process of Styrofoam “decomposition” is not true biodegradation but rather a slow fragmentation. It involves several environmental factors that gradually break the material into smaller pieces over centuries.

Step 1: Initial Exposure and Physical Weathering

Upon disposal, Styrofoam is immediately exposed to environmental elements like wind, rain, and temperature fluctuations. These physical forces, along with abrasion from other waste, begin to break the larger pieces of Styrofoam into smaller fragments. This is the very first stage of its breakdown.

This initial physical weathering is crucial as it increases the surface area of the Styrofoam. While not chemical decomposition, the creation of smaller pieces makes the material more susceptible to subsequent environmental impacts, accelerating its fragmentation process over time.

Step 2: Photodegradation

Sunlight, specifically its ultraviolet (UV) radiation, plays a significant role in the breakdown of Styrofoam. This process, known as photodegradation, causes the polymer chains in polystyrene to become brittle and break down.

However, photodegradation only affects the surface layers of the Styrofoam. In landfills, where sunlight penetration is limited, this process is severely inhibited, allowing the material to persist largely intact for extended periods.

Step 3: Oxidation

Over very long periods, Styrofoam can undergo a slow process of oxidation. This involves the reaction of oxygen with the polymer chains in the polystyrene, leading to a gradual breakdown of these chains into smaller molecules.

This chemical degradation is extremely slow and generally not a significant factor in the overall breakdown of Styrofoam in natural environments. It requires specific conditions and prolonged exposure to be effective.

Step 4: Biological Interaction (Limited)

Unlike organic materials, Styrofoam is largely resistant to biological degradation by microorganisms such as bacteria and fungi. These organisms lack the necessary enzymes to break down the complex chemical structure of polystyrene.

While some studies have identified certain microorganisms capable of very slow degradation, this process is not widespread or efficient enough to significantly impact the vast quantities of Styrofoam waste accumulated globally.

Step 5: Microplastic Formation and Persistence

The culmination of these processes is the formation of microplastics. As Styrofoam fragments physically and undergoes limited chemical changes, it breaks down into increasingly tiny pieces, often microscopic in size.

These microplastics do not disappear; they persist in the environment for hundreds to thousands of years. They contaminate soil, water, and air, posing long-term ecological threats and entering food chains.

Recycling and Disposal of Styrofoam

Styrofoam, also known as expanded polystyrene (EPS), poses significant challenges when it comes to recycling and disposal. Faced with the question of how long does it take for styrofoam to decompose, recycling is more meaningful. Here are some methods for recycling and disposal:

Recycling:

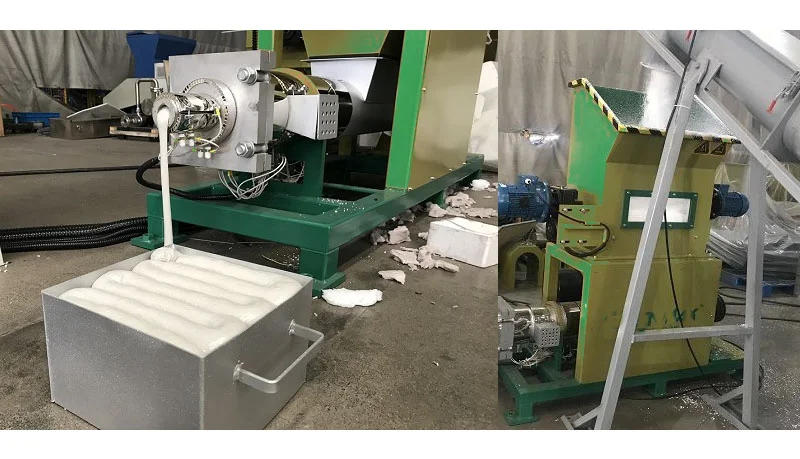

While Styrofoam can be recycled, the process is not as common or widespread as for other materials like paper, plastic, or glass. Some recycling centers and facilities accept clean and dry Styrofoam for recycling. The material is usually compacted and melted down to be reused in the production of new plastic products. Check with your local recycling facility to see if they accept Styrofoam and if there are any specific requirements for preparation.

Drop-off Locations:

Some communities have specific drop-off locations or events where residents can bring their Styrofoam for recycling. These locations may be run by local governments, waste management companies, or nonprofit organizations. Again, it’s essential to ensure the Styrofoam is clean and dry before dropping it off.

Mail-back Programs:

Some companies offer mail-back programs where consumers can send their used Styrofoam packaging back to be recycled. This can be a convenient option for individuals who don’t have access to local recycling facilities.

Reuse:

Another eco-friendly option is to reuse Styrofoam packaging whenever possible. This could involve using it for packaging fragile items when shipping or storing goods. While reuse doesn’t eliminate the eventual need for disposal, it can extend the life of the material and reduce the overall amount of waste generated.

Proper Disposal:

If recycling or reuse options are not available, Styrofoam should be disposed of properly to minimize its environmental impact. This typically means placing it in the regular trash, but efforts should be made to reduce its volume as much as possible to conserve landfill space. Some communities may have specific guidelines for Styrofoam disposal, so it’s worth checking with local authorities for guidance.

In conclusion, while Styrofoam recycling options may be limited compared to other materials, there are still ways to responsibly manage its disposal and reduce its environmental footprint. Efforts to increase awareness, improve recycling infrastructure, and promote alternative packaging materials can help address this challenge in the long term.

FAQs

How long does it take for Styrofoam to decompose naturally?

Styrofoam, also known as polystyrene, does not decompose naturally in a practical sense. It can take hundreds of years or even 500-1000 years to decompose in landfills under typical conditions.

Can Styrofoam be reused or recycled?

While some types of polystyrene can be recycled, the process is quite limited. The recycling infrastructure for polystyrene is not as widespread as for other materials, and not all types of polystyrene can be recycled.

What happens when Styrofoam ends up in the ocean?

When Styrofoam enters the ocean, it can harm marine life through ingestion or entanglement. It can also break down into microplastics, which accumulate in the food chain and pose a threat to everything from small marine organisms to large fish and marine mammals.

Conclusion

The stark reality of Styrofoam’s longevity in our environment underscores the urgent need for sustainable alternatives and responsible disposal. Its persistent nature, breaking down into microplastics rather than truly decomposing, presents a long-term threat to ecosystems and potentially human health.

As consumers and businesses, we have a crucial role to play in mitigating this impact. Choosing reusable products, supporting companies that utilize eco-friendly packaging, and advocating for better recycling infrastructure are vital steps.

For businesses seeking sustainable solutions, consider wholesale expanded polystyrene (EPS) options from Epsole. Our innovative materials offer performance without the enduring environmental burden, helping you contribute to a greener future.