Geofoam fill is a lightweight, durable, and highly versatile material used in civil engineering and construction. Made from expanded polystyrene (EPS), it’s an excellent alternative to traditional soil and aggregate fills. This guide will explore what geofoam is, its unique properties, and why it’s becoming a go-to solution for various projects.

From road construction and retaining walls to stadium seating and building foundations, geofoam’s applications are vast. Its ability to reduce vertical stress on underground utilities, prevent soil settlement, and provide excellent thermal insulation makes it a top choice for modern construction. We’ll delve into the many ways geofoam is revolutionizing the industry.

What Is Geofoam Fill?

Geofoam fill is a lightweight, engineered material made from expanded polystyrene (EPS), used as a superior alternative to traditional fill materials in construction. Known for its low density and high compressive strength, geofoam fill provides excellent support while significantly reducing the load on underlying soils and structures.

Geofoam fill is an engineered, lightweight fill material made from expanded polystyrene (EPS) or extruded polystyrene (XPS), which are essentially the same material used for common foam products. It is produced in large, rigid blocks and is known for its exceptional light weight (about 1% the density of soil), high compressive strength, and durability.

This makes it an ideal alternative to traditional fill materials like soil or gravel in various construction and civil engineering applications. Its primary function is to reduce the load on underlying soils and structures, prevent settlement, and provide excellent insulation, making it a versatile and cost-effective solution for a wide range of projects.

Composition Of Geofoam Fill

What is geofoam made of?

Geofoam fill is primarily composed of expanded polystyrene (EPS), a lightweight, closed-cell foam material. This composition involves the expansion of polystyrene beads, which are then fused together to form large blocks or panels. The resulting EPS blocks have low density, high compressive strength, and remarkable stability.

Geofoam is a lightweight, engineered fill material primarily composed of expanded polystyrene (EPS) or sometimes extruded polystyrene (XPS). The material is made from tiny plastic beads of polystyrene that are expanded with a blowing agent, such as pentane gas, and then molded into large blocks.

The final product is a rigid, cellular foam structure that is predominantly air—around 98%—with only about 2% plastic. This composition gives geofoam its defining properties, including its incredibly light weight and high compressive strength. The primary components are:

- Air: The main component of the final product, trapped within the closed-cell structure, which accounts for the material’s low density and excellent insulation properties.

- Polystyrene: The base polymer that forms the cellular structure of the material.

- Pentane: A blowing agent used during the manufacturing process to cause the polystyrene beads to expand.

Is Geofoam the Same as Styrofoam?

While people often use “Styrofoam” as a general term for any expanded polystyrene (EPS) foam, it is a common misconception. Geofoam is a specific type of engineered expanded polystyrene (EPS) or extruded polystyrene (XPS) foam designed for construction and civil engineering applications. The key differences lie in their manufacturing process, properties, and intended uses.

- Manufacturing Process: Geofoam (EPS) is made by expanding tiny polystyrene beads with steam in a mold, resulting in a closed-cell foam with a bead-like appearance. Styrofoam™ (XPS) is produced by a continuous extrusion process, which gives it a smoother surface and slightly different properties.

- Styrofoam™ is a brand name: It is a trademarked product by The Dow Chemical Company and is specifically a blue-colored, extruded polystyrene (XPS) foam used primarily for thermal insulation.

- Geofoam is a material classification: It refers to large, lightweight blocks of expanded polystyrene (EPS) or sometimes extruded polystyrene (XPS) that are specifically manufactured to meet geotechnical standards (ASTM D6817).

Strength Of Geofoam Filling?

Lightweight Nature

Geofoam filling’s exceptionally lightweight nature offers significant advantages in construction. By using geofoam instead of traditional fill materials like soil or gravel, the load on underlying soils and structures is drastically reduced.

This reduction is particularly beneficial in projects such as roadways, embankments, and slope stabilization, where minimizing weight can prevent settlement, erosion, and structural damage over time. Additionally, geofoam’s low weight simplifies transportation and installation, contributing to overall project efficiency and cost-effectiveness.

High Compressive Strength

Geofoam is exceptionally lightweight yet exhibits robust compressive strength, making it capable of supporting substantial loads without deforming. This quality ensures stability and structural integrity in diverse construction applications, including roadways, embankments, and foundations. Its ability to distribute weight evenly helps prevent settling and ensures the long-lasting performance of infrastructure projects.

Easy Installation

Geofoam’s ease of handling and installation stems from its lightweight properties and versatility. It can be accurately cut and shaped to exact project requirements, streamlining construction timelines and minimizing labor expenses.

Furthermore, its low weight facilitates simpler transportation and positioning on-site, reducing logistical complexities and equipment requirements. These attributes collectively enhance efficiency and cost-effectiveness in construction projects using geofoam.

Cost-Effectiveness

Utilizing geofoam offers significant cost savings by minimizing expenses in various aspects of construction. Its lightweight composition diminishes the necessity for extensive ground preparation and heavy machinery, cutting down on associated costs.

Moreover, its straightforward installation process accelerates project completion, thereby reducing labor hours and equipment usage. These combined benefits make geofoam a cost-effective choice for enhancing efficiency and budget management in construction projects.

Versatility

Geofoam’s versatility allows it to excel in diverse construction applications. Whether used for roadways, embankments, foundation insulation, retaining walls, or landscaping, geofoam adapts readily to varying project requirements.

Its ability to be tailored through cutting and shaping ensures precise fitment, enhancing its utility across different engineering and architectural contexts. This adaptability makes geofoam a versatile solution for addressing specific construction challenges effectively.

Durability

Geofoam’s durability is ensured by its resistance to water absorption, a feature that prevents degradation over time. This resilience allows geofoam to maintain its structural integrity and strength, even in harsh environmental conditions. Engineers and builders can rely on geofoam for long-term stability in various construction projects, confident that it will withstand the rigors of moisture exposure and continue to perform reliably over its lifespan.

Environmental Benefits

Using geofoam can have positive environmental impacts. Its lightweight nature reduces the need for extensive excavation and transport of heavy materials, leading to lower fuel consumption and emissions. Additionally, geofoam is often made from recyclable materials, contributing to sustainability efforts.

Thermal Insulation

Geofoam’s excellent thermal insulation properties contribute significantly to energy efficiency in buildings. By insulating foundations, geofoam helps minimize heat transfer through walls and floors, reducing the need for heating and cooling. This capability not only enhances comfort but also lowers energy costs, making geofoam a practical choice for sustainable building practices aimed at improving overall energy efficiency and reducing environmental impact.

Disadvantage Of Geofoam Lightweight Fill

Limited Load-Bearing Capacity

Geofoam’s notable compressive strength makes it suitable for many construction applications, but engineers should consider its limitations. In projects needing exceptionally high load-bearing capacities or stringent settlement criteria, other materials might be more appropriate. Careful evaluation and precise project design are essential to determine if geofoam can meet specific load and stability requirements effectively.

Long-Term Creep Behavior

Geofoam, similar to other plastic materials, may experience long-term creep when subjected to sustained loads. Creep refers to the gradual deformation over time under constant stress, which can impact structural performance if not adequately considered during design and installation processes. Engineers must account for potential creep effects to ensure that geofoam installations maintain their intended stability and structural integrity throughout their operational lifespan.

How Long Does Geofoam Last?

Geofoam is an exceptionally durable and long-lasting material, with a lifespan that can range from 50 to 100 years or even longer when properly installed. It is essentially inert and non-biodegradable, meaning it will not rot, decompose, or leach chemicals into the ground over time.

Its longevity is dependent on protecting it from a few key factors: exposure to UV radiation (sunlight) and contact with hydrocarbon chemicals like gasoline and diesel, both of which can cause degradation. In most applications, geofoam is buried or covered, which naturally protects it from these elements. With proper installation and design considerations, geofoam retains its physical properties and structural integrity for the entire service life of the project.

Does Geofoam Absorb Water?

Geofoam is highly water-resistant, but it is not completely waterproof. Because it is composed of a closed-cell foam structure, it doesn’t readily absorb water like a sponge. Water can only enter the material through tiny spaces between the fused polystyrene beads.

This means that even when submerged, geofoam absorbs only a very small amount of water (typically less than 4% by volume), which has a negligible effect on its strength and mechanical properties. This low absorption rate is a key reason for its use in projects where moisture is a concern.

- Maintains Properties: Geofoam continues to function effectively as a lightweight fill and insulator even in moist conditions.

- Water-resistant, not waterproof: Geofoam repels most water but isn’t 100% impervious.

- Minimal Absorption: Even when submerged for long periods, it absorbs a very small amount of water.

- Negligible Impact: The small amount of water absorbed does not significantly affect its physical strength or performance.

Where Is Geofoam Fill Used?

Road Construction

Geofoam fill is extensively utilized in road construction projects. It serves as lightweight fill material beneath roadways, highways, and airport runways. By reducing the load on underlying soils, geofoam helps prevent settlement and extends the lifespan of pavements. It also improves the performance of the road surface by providing stable support for heavy traffic loads.

Embankments And Slope Stabilization

In civil engineering, geofoam fill is used to stabilize embankments and slopes. Its high compressive strength allows it to resist erosion and maintain the stability of slopes over time. Geofoam fill is particularly beneficial in areas where conventional fill materials may be too heavy or prone to settling.

Foundation Insulation

Geofoam fill is used in building foundations to effectively mitigate soil pressure and minimize settlement risks. Its lightweight yet stable properties create a solid base that distributes structural loads evenly. This ensures foundations remain level and intact, safeguarding against uneven settling caused by soil movement and moisture fluctuations.

By bolstering stability, geofoam enhances the longevity and performance of building foundations, making it a reliable choice in construction projects.

Retaining Walls

Geofoam is an ideal choice for use behind retaining walls due to its ability to reduce lateral earth pressures effectively. Its lightweight composition simplifies handling and installation, offering advantages over heavier traditional backfill materials. This feature not only streamlines construction processes but also enhances the overall stability and longevity of retaining wall structures by minimizing stress and load.

Landscaping And Green Roofs

Geofoam’s popularity in landscaping and green roof projects stems from its lightweight properties, which effectively reduce the load on underlying structures. Despite its low weight, geofoam provides robust support for vegetation and landscaping features, ensuring stability without compromising structural integrity. This makes it an ideal choice for creating sustainable and aesthetically pleasing outdoor spaces.

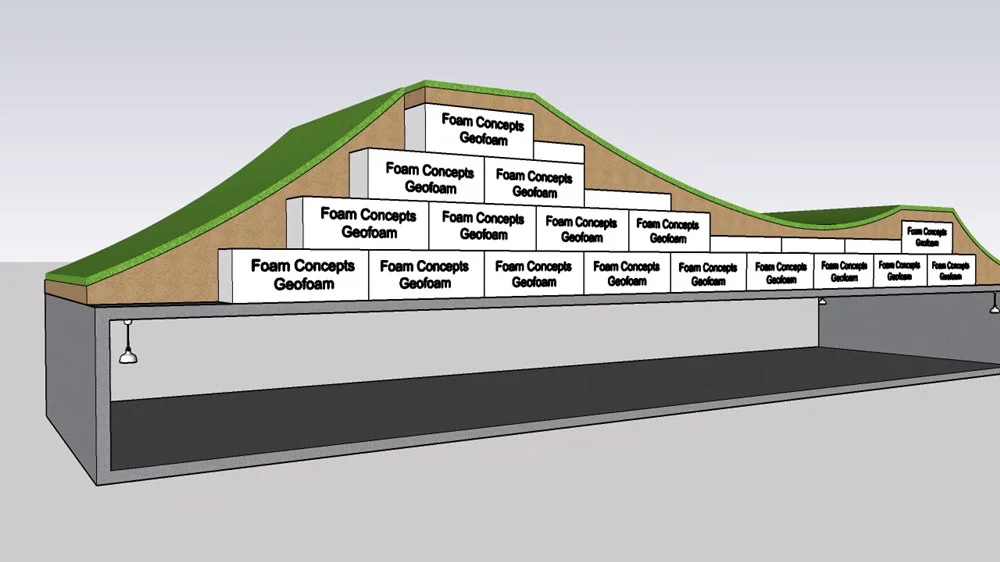

Infrastructure Projects

Geofoam finds extensive use in critical infrastructure projects like airports, railways, and tunnels due to its lightweight properties. It effectively minimizes settlement while enhancing stability without imposing significant weight on underlying soils or structures. This makes geofoam an ideal choice for supporting heavy loads while maintaining structural integrity in crucial engineering applications.

How Much Does Geofoam Cost?

The cost of geofoam depends on several factors:

Density

Geofoam is available in a range of densities, typically from 0.7 to 2.85 pounds per cubic foot (pcf). Higher densities incur greater costs because they require more materials and involve more intensive manufacturing processes. The density of geofoam chosen for a project depends on specific engineering requirements, such as load-bearing capacity and structural needs, balancing performance with cost considerations.

Volume And Thickness

The cost of your project is directly influenced by the volume and thickness of the material required. Larger quantities and thicker layers necessitate more material, labor, and possibly specialized equipment, resulting in higher overall expenses. It’s essential to carefully plan and calculate these factors to manage project budgets effectively.

Transportation

Shipping expenses are a significant factor in total project costs, particularly when the construction site is far from the manufacturer or supplier. Costs can escalate due to transportation distances, fuel prices, logistics, and handling fees, all influencing the overall budget allocation for materials and supplies. Efficient logistical planning and supplier selection can mitigate these costs, ensuring budget efficiency in construction projects.

Installation

Installing geofoam incurs labor costs primarily for cutting, shaping, and precise placement. These tasks require skilled labor and specialized equipment, contributing to the overall project expenditure. Despite these costs, geofoam’s ease of handling and installation often offsets expenses by reducing the need for extensive ground preparation and heavy machinery, leading to potential long-term savings in construction projects.

Supplier And Location

The prices of geofoam can fluctuate based on several factors such as supplier rates, regional demand, product availability, and local economic conditions. Higher demand in certain regions or limited availability can lead to price increases, while stable supply and lower demand may result in more competitive pricing.

Local economic factors, including labor costs and transportation expenses, also influence geofoam prices, making them variable across different markets and regions.

What Is The Standard For Geofoam Filling?

The standards for geofoam filling are established to ensure consistency, quality, and performance in construction applications. These standards typically govern the manufacturing, testing, and installation of geofoam materials. They encompass criteria such as material composition, density specifications, compressive strength requirements, dimensional tolerances, and durability expectations.

Adhering to these standards ensures that geofoam filling meets engineering and safety standards, providing reliable support and longevity in infrastructure projects ranging from roadways and embankments to building foundations and slope stabilization.

Conclusion

In conclusion, geofoam fill emerges as a versatile and effective solution for modern construction challenges. Its lightweight nature, coupled with impressive compressive strength, offers substantial advantages across various applications. From enhancing stability in roadways and embankments to providing efficient insulation in building foundations, geofoam proves instrumental in reducing project costs and timelines.

Moreover, its durability and resistance to water absorption ensure long-term performance, making it a reliable choice for sustainable infrastructure development. As engineering practices evolve, geofoam continues to demonstrate its value as a durable, cost-effective, and environmentally friendly fill material, poised to meet the demands of future construction needs.