When it comes to construction and packaging, the Expanded Polystyrene (EPS) melting point is a critical, yet often overlooked, property. This seemingly simple piece of information dictates everything from the material’s fire safety rating to its suitability for various thermal applications. Understanding the EPS melting point is essential for ensuring the performance and integrity of products and structures.

The thermal properties of EPS make it an excellent insulator, but this benefit comes with a specific heat limitation. Knowing the exact temperature at which EPS begins to deform and soften is not just an academic exercise—it’s a practical necessity for engineers, designers, and manufacturers. This knowledge is key to preventing material failure and ensuring products meet industry standards.

What Is Expanded Polystyrene (EPS)?

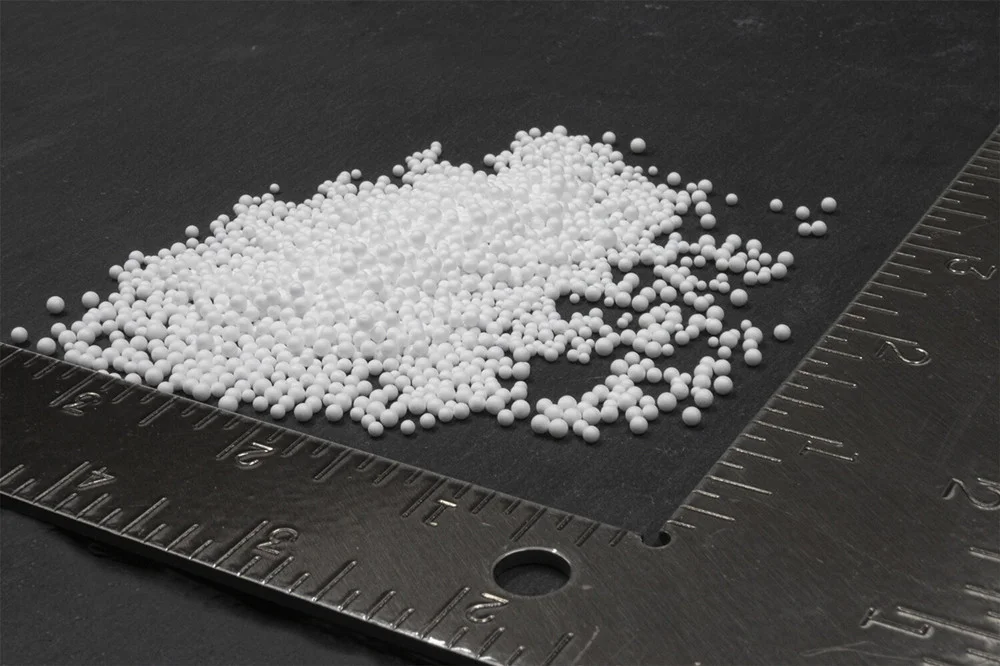

Expanded Polystyrene (EPS) is a lightweight plastic material known for its excellent insulation properties. It’s created by expanding polystyrene beads, resulting in a cellular structure filled with air pockets. EPS is widely used in packaging, construction insulation, and various other applications due to its low density, strength, and thermal insulation capabilities.

What Is Expanded Polystyrene Melting Point?

The melting point of Expanded Polystyrene (EPS) typically falls within the range of 90°C to 105°C (194°F to 221°F).

However, it’s important to note that EPS does not technically “melt” like metals or some other plastics. Instead, it softens and begins to lose its structural integrity when exposed to heat, eventually turning into a viscous liquid.

This temperature range is significant in applications where EPS products may encounter heat sources, helping to prevent deformation or damage.

Affecting Factors Of Expanded Polystyrene Melting Point

Density: indicating mass per volume, impacts expanded polystyrene melting point. Lower-density EPS foam correlates with reduced melting points due to increased air voids, a primary factor leading to decreased melting points.

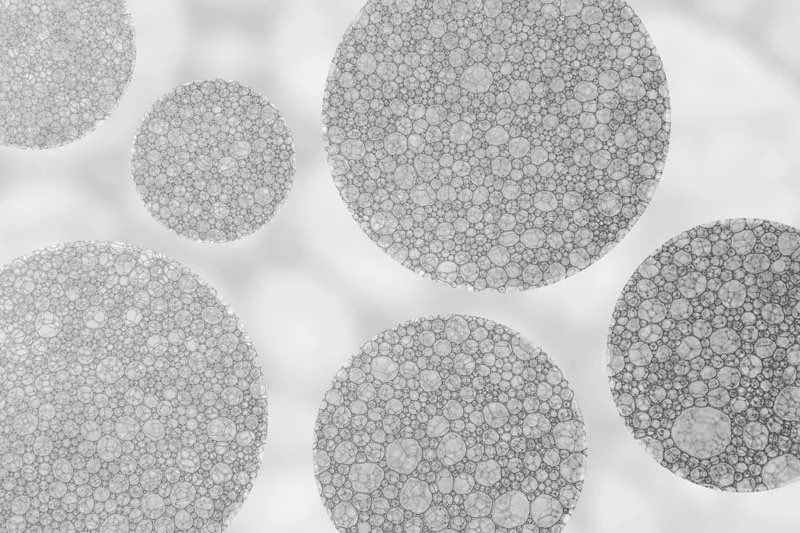

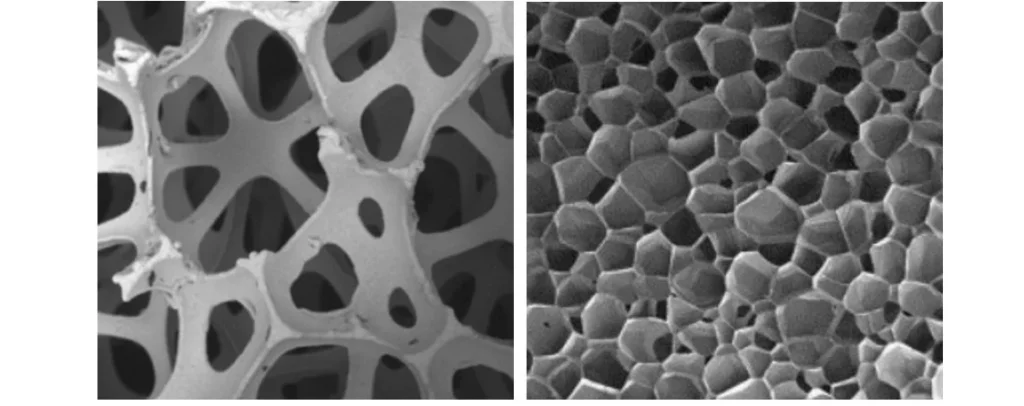

Morphology: Morphology encompasses EPS foam’s shape and structure, featuring two pore types: open-cell and closed-cell. Open-cell pores possess channels, while closed-cell pores lack them. Closed-cell EPS foam typically exhibits a higher melting point due to its compact structure and slower heat transfer rate, necessitating a higher temperature for melting.

This arises from the reduced permeability of closed-cell foam, impeding heat transfer and elevating the thermal resistance. Consequently, closed-cell EPS foam demonstrates enhanced thermal stability compared to open-cell variants, making it advantageous in applications requiring heightened heat resistance.

- Molecular Weight: Polystyrene with higher molecular weight tends to have a higher melting point because of stronger intermolecular forces.

- Additives: The inclusion of additives, such as flame retardants or reinforcing agents, can alter the expanded polystyrene melting point.

- Thermal History: The processing conditions during EPS production and any previous exposure to heat can affect its melting behavior.

- Environmental Conditions: Humidity, atmospheric pressure, and other environmental factors can influence expanded polystyrene melting point, albeit to a lesser extent.

How To Test Expanded Polystyrene Melting Point?

Testing the melting point of expanded polystyrene (EPS) is crucial for ensuring its suitability in various applications. While EPS does not have a sharp melting point like metals, it undergoes a crucial thermal transition where it softens and deforms. This process helps determine its heat resistance and temperature limits.

Step 1: Sample Preparation and Equipment

The process begins with preparing a uniform EPS sample. It should be a clean piece of EPS foam with a consistent size and shape to ensure accurate results. The main equipment needed is a heating apparatus capable of gradual, controlled heating and an accurate thermometer or temperature probe to monitor the temperature.

This initial step is critical for a valid test. Uniformity ensures that the entire sample heats at a consistent rate, avoiding discrepancies in results. Using reliable equipment for both heating and temperature measurement minimizes errors, providing a more precise melting point determination.

Step 2: Controlled Heating and Observation

Place the EPS sample in the heating apparatus. Increase the temperature at a slow, controlled rate, such as a few degrees Celsius per minute. Carefully observe the sample for any physical changes as the temperature rises.

During this phase, you are looking for the point at which the EPS loses its structural integrity. The visual cues to watch for are softening, shrinking, and deforming. Note the temperature at the exact moment these changes become noticeable, as this is the EPS’s softening point.

Step 3: Data Collection and Analysis

Record the temperature at which the EPS sample shows signs of softening or deformation. For improved accuracy, repeat the test with multiple samples and calculate the average temperature. This average value represents the practical EPS melting point for that specific material.

Analyzing the data helps confirm the thermal limitations of the EPS. You can compare your results to established standards for different EPS densities to validate the test’s accuracy. This information is vital for applications where EPS will be exposed to elevated temperatures.

What Is Expanded Polystyrene Heat Resistance?

Expanded Polystyrene (EPS) exhibits moderate heat resistance, typically softening and deforming at temperatures ranging from 90°C to 105°C (194°F to 221°F). However, EPS does not technically “melt” like metals or some other plastics; instead, it undergoes a transition from a solid to a viscous state as it reaches its softening point.

While EPS can withstand brief exposure to moderate heat, prolonged or intense heat exposure can cause it to deform permanently or even ignite. Therefore, it’s essential to consider EPS’s heat resistance when selecting materials for applications where heat exposure is a concern. Additionally, various additives or treatments can be incorporated into EPS to enhance its heat resistance for specific applications.

How Polystyrene Melting Point Affect Product’s Performance

The melting point of polystyrene significantly impacts a product’s performance by determining its heat resistance and processing limitations. Polystyrene’s relatively low softening point makes it unsuitable for high-temperature applications like microwave use, as the material can easily deform. This property is both a constraint and an advantage, influencing its use in various industries.

Product Safety and Application: The material’s heat limitation is a critical safety consideration. Products like consumer electronics housings and children’s toys must be designed with the knowledge that excessive heat exposure could cause warping or failure.

Thermal Stability: The melting point dictates the maximum temperature a product can withstand without losing its shape or structural integrity. Products like disposable cups or insulated food containers rely on a stable temperature below this point to function correctly.

Manufacturing Process: Polystyrene’s low melting point and glass transition temperature (around 100°C) make it easy to mold and shape during manufacturing. This allows for cost-effective and energy-efficient production processes like injection molding and thermoforming.

The Relationship Of Expanded Polystyrene Melting Point And Heat Resistance

The expanded polystyrene melting point is closely linked to its heat resistance. Generally, EPS softens and deforms when exposed to heat, with its melting point typically falling between 90°C to 105°C (194°F to 221°F). While EPS exhibits some heat resistance within this range, it’s important to note that prolonged exposure to elevated temperatures can cause permanent deformation or even ignition.

Expanded polystyrene melting point serves as a critical threshold for understanding EPS’s behavior under heat. Below this point, EPS retains its structural integrity, but as temperatures approach or exceed the melting point, it becomes increasingly susceptible to softening and deformation.

Therefore, in applications where heat resistance is paramount, it’s essential to consider EPS’s melting point and select appropriate materials or employ additional measures to mitigate the effects of heat exposure.

Applications Of Expanded Polystyrene Melting Point

Understanding the expanded polystyrene melting point is crucial for various applications where heat resistance is a concern. Some key applications include:

Packaging:

EPS is commonly used in packaging fragile items such as electronics, glassware, and pharmaceuticals. Knowledge of its melting point helps ensure that EPS packaging maintains its structural integrity during transit and storage, even when exposed to moderate heat.

Construction:

EPS foam is widely used as insulation in buildings to improve energy efficiency and maintain comfortable indoor temperatures. By considering its melting point, architects and builders can select EPS products that withstand the temperatures encountered during construction and the lifespan of the building.

Marine And Buoyancy Applications:

EPS foam is used in marine applications such as buoys, floating docks, and marine flotation devices. Understanding its melting point helps ensure that EPS components can withstand exposure to sunlight and heat while maintaining buoyancy and structural integrity.

Transportation:

The automotive and aerospace industries use EPS for its lightweight and insulating properties. Understanding its melting point ensures that EPS components in vehicles and aircraft can withstand the heat generated by engines and other mechanical systems.

Conclusion

The EPS melting point is a fundamental property that influences the material’s safe and effective use across countless industries. From protecting sensitive goods during shipping to providing insulation in buildings, its thermal limitations must be respected. Ignoring these properties can lead to catastrophic failures, compromising both product quality and safety.

Properly understanding the thermal behavior of EPS allows for its innovative and sustainable application. By recognizing its melting point, we can develop new methods for recycling and repurposing the material, minimizing waste and maximizing its lifecycle. This knowledge is a cornerstone of responsible and efficient material management.

For all your EPS needs, from construction to custom packaging, look no further. You can get wholesale EPS materials and products from our trusted source, Epsole. We provide high-quality, reliable EPS that meets the most demanding specifications for your projects.