Expanded polystyrene is widely used in construction for its lightweight structure and thermal insulation properties. As building safety requirements increase, fire performance has become a critical concern. Understanding expanded polystyrene fire ratings helps builders and buyers evaluate how flame retardants improve material behavior during fire exposure.

Flame-retardant EPS is engineered to slow flame spread and reduce fire risks in building applications. By examining fire ratings, testing standards, and material improvements, this blog explains how flame retardants enhance safety while maintaining insulation efficiency, durability, and practical performance across walls, roofs, ceilings, and insulated panel systems.

What Is Expanded Polystyrene?

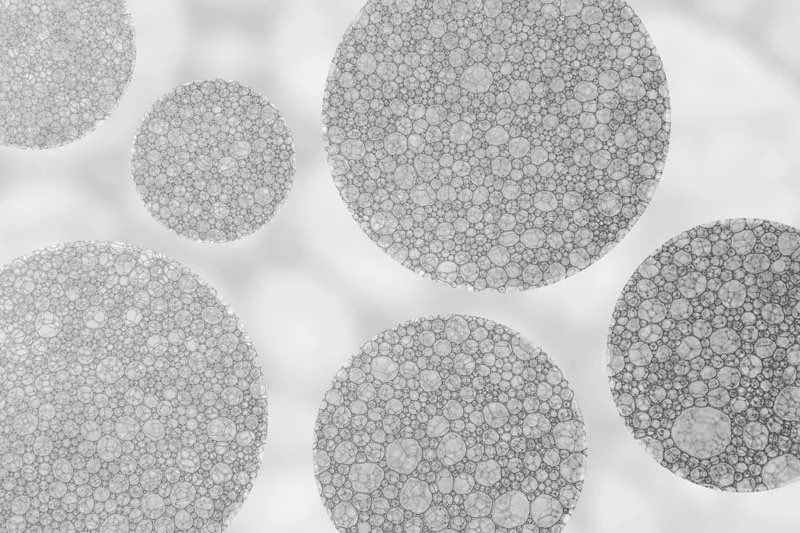

Expanded Polystyrene (EPS) is a lightweight, rigid, and versatile plastic material commonly used for insulation, packaging, and construction. It is characterized by its cellular structure, thermal insulation properties, and shock absorption capabilities.

What are Expanded Polystyrene Fire Ratings

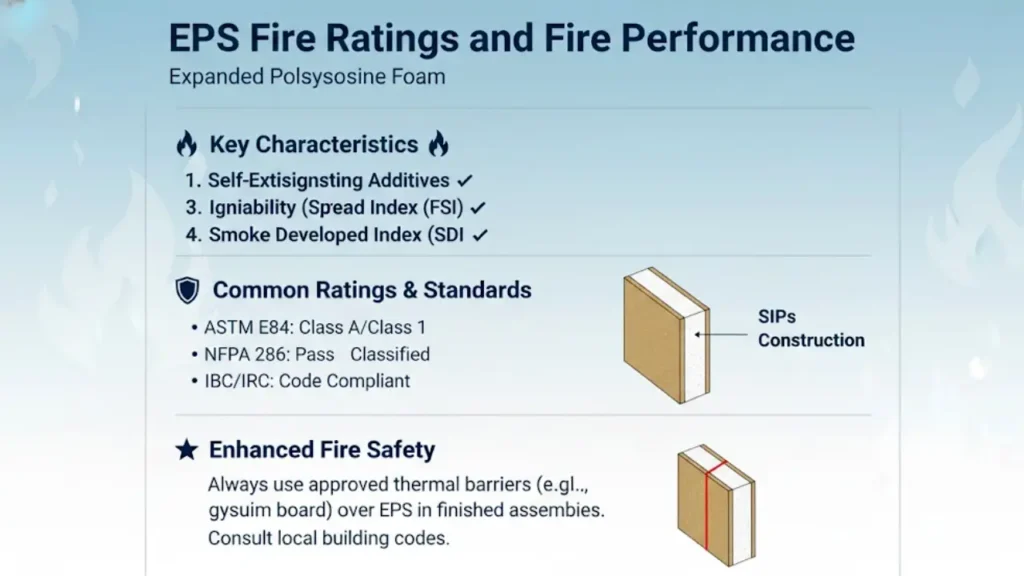

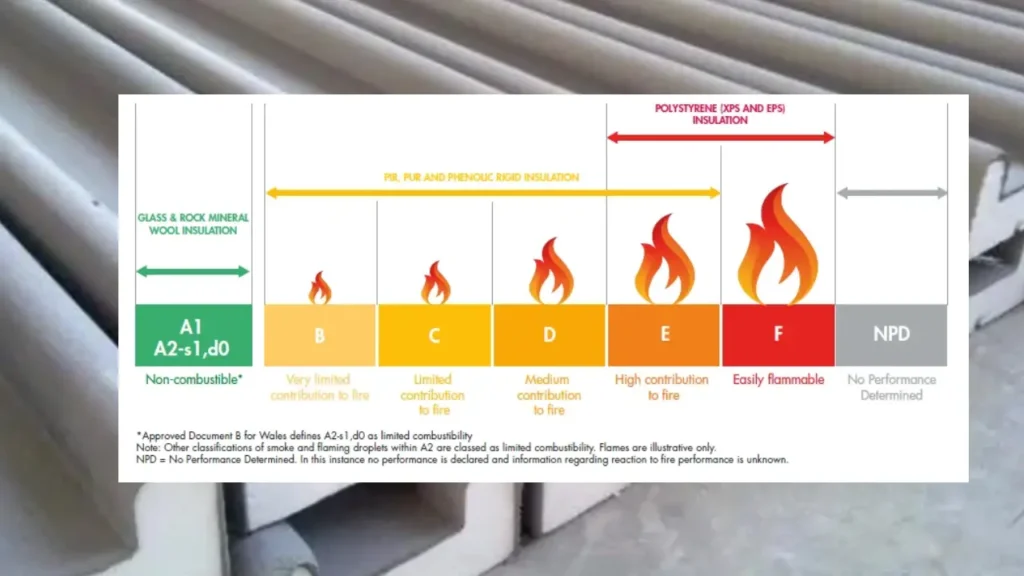

Expanded Polystyrene (EPS) fire ratings are standardized classifications that evaluate the fire resistance and behavior of EPS materials. These ratings are determined through rigorous testing protocols, such as the ASTM E84 or European EN 13501-1 standards, which assess factors like flame spread, smoke production, and ignitability.

The ratings provide crucial information for ensuring that EPS products used in applications like construction and insulation meet fire safety regulations. While EPS is inherently a combustible material, its fire performance is significantly enhanced with the addition of flame-retardant additives, which allow it to achieve a better fire rating and even self-extinguish when the ignition source is removed.

Expanded Polystyrene Fire Rating Characteristics

Low Combustibility

EPS has a low flammability, meaning it is less likely to ignite compared to other materials. This inherent property reduces the risk of flames spreading.

Flame Retardancy

Some EPS products are treated with flame-retardant additives during manufacturing. These additives help to inhibit the combustion process and slow down the spread of flames.

Limited Smoke Emission

When exposed to fire, EPS tends to produce relatively low levels of smoke compared to some other materials. This characteristic helps maintain visibility and reduces health risks associated with smoke inhalation during fire incidents.

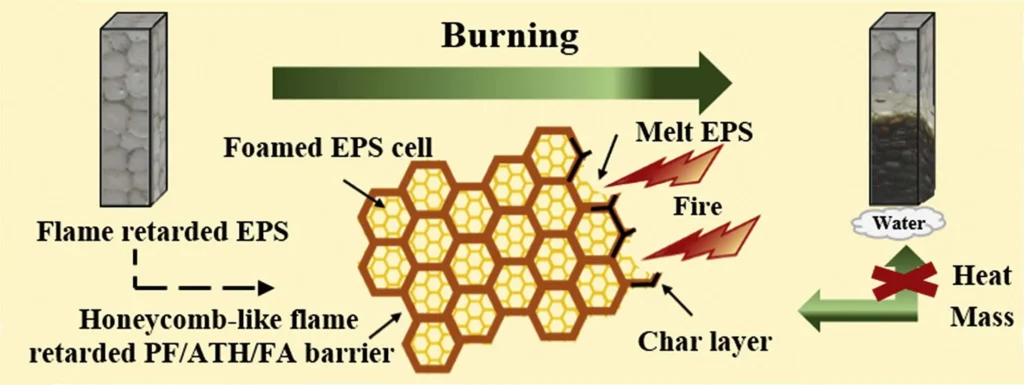

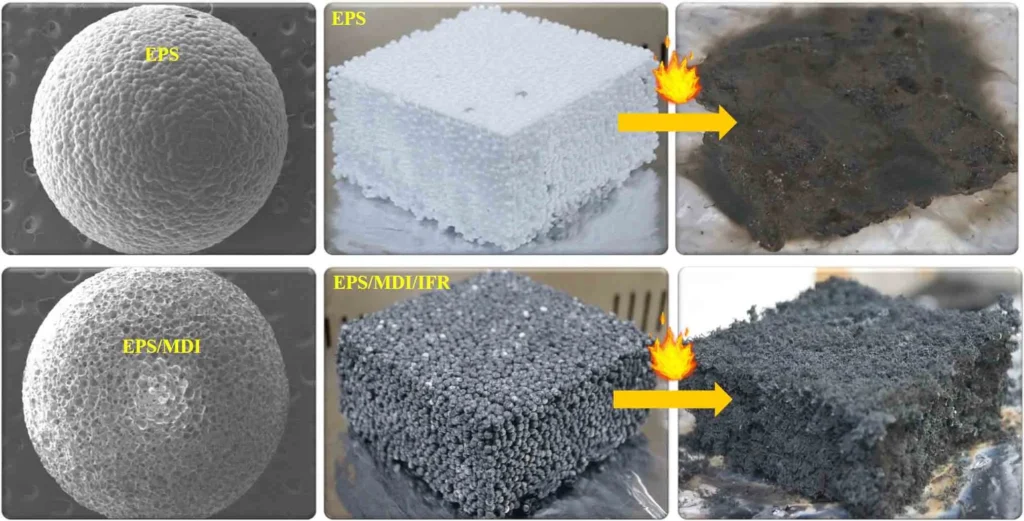

Formation of Char Layer

When exposed to fire, EPS may char rather than burn completely. This char layer acts as a protective barrier, insulating the underlying EPS material and slowing down the progression of flames.

Compliance with Standards

EPS products are subjected to rigorous testing and certification to ensure they meet specific fire safety standards and regulations. Compliance with these standards provides assurance of the material’s fire resistance and suitability for use in various applications.

Is Polystyrene Flammable?

Yes, polystyrene is flammable. As a hydrocarbon-based polymer, it is a combustible material. It will ignite when exposed to a direct flame or high heat, and once it catches fire, it can burn and melt rapidly. This can lead to the release of heat, toxic smoke, and flaming droplets, which can spread the fire further.

To address these fire hazards, most polystyrene used in building and construction applications is treated with flame-retardant additives. These additives help to inhibit the combustion process, allowing the material to self-extinguish when the ignition source is removed. Even with these additives, fire safety precautions and compliance with building codes are crucial.

EPS Panels Fire Risk

EPS panels are widely used for their insulation and lightweight properties, but fire safety is a key consideration in construction. While EPS provides excellent thermal performance, it is combustible and can contribute to fire spread if not properly treated.

Understanding fire risks and protective measures ensures safe and compliant building applications.

- Design Considerations for Safety – Strategic panel placement, adequate ventilation, and integration with fire-resistant materials reduce overall fire risk. We guide clients in choosing the right panel types and configurations to optimize both safety and building performance.

- Combustibility of EPS Cores – EPS insulation can ignite and burn when exposed to open flames. Without fire-retardant treatment, it may release toxic smoke. Using treated EPS cores and following fire safety codes significantly reduces risks in building projects.

- OSB Surface Contribution – Oriented strand board (OSB) is also combustible, and combined with EPS, panels can accelerate fire spread. Protective coatings, fire-rated boards, or cladding can enhance safety, ensuring walls, floors, and roofs meet regulatory standards.

- Fire Retardant Treatments – We offer EPS panels treated with fire-resistant chemicals that slow ignition and flame propagation. These treatments improve panel safety without compromising insulation or structural performance, making them suitable for residential, commercial, and industrial buildings.

- Building Code Compliance – Correct panel installation, fire barriers, and code-adherent construction practices help mitigate fire hazards. Following local regulations ensures panels perform safely in emergency scenarios, protecting occupants and property while maintaining the panels’ energy efficiency benefits.

Why Expanded Polystyrene Fire Ratings Are Important

Understanding Expanded Polystyrene (EPS) fire ratings is crucial for ensuring the safety of buildings and products. These ratings provide a standardized measure of how the material will behave in a fire, which is essential for compliance and risk management.

Ensuring Fire Safety

Fire safety is paramount in any application involving EPS. Without proper precautions, EPS can pose significant fire hazards due to its combustible nature. Therefore, implementing effective fire safety measures is essential to mitigate risks and ensure the protection of both property and lives.

Understanding Expanded Polystyrene Fire Ratings

Expanded Polystyrene Fire Ratings assess fire resistance and performance, determined through rigorous testing methods and standards set by regulatory bodies. They evaluate factors like ignition resistance, flame spread, and smoke production, offering valuable insights into EPS behavior in fire scenarios.

Compliance with Regulations

Compliance with EPS fire safety regulations and standards is vital to ensure material suitability and safety. These regulations establish minimum fire performance criteria for EPS products, aiding in preventing fire incidents and ensuring legal compliance and liability protection.

Minimizing Fire Risks

Expanded Polystyrene Fire Ratings help stakeholders select materials for construction, packaging, and insulation. Choosing EPS with suitable ratings minimizes fire risks, protecting property and lives. Additionally, fire-rated EPS can lower insurance premiums and liability risks for building owners and contractors.

Enhancing Building Safety

Expanded Polystyrene Fire Ratings enhance building safety by ensuring structures have fire-resistant materials. Architects and engineers can create safer environments by incorporating fire-rated EPS into building designs, prioritizing the safety of occupants and emergency responders.

How to Test Expanded Polystyrene Fire Ratings?

Testing methods for Expanded Polystyrene Fire Ratings involve standardized procedures to assess the material’s fire resistance. This includes controlled laboratory testing following specific standards like ASTM, UL, European (EN), and Chinese national standards.

Commonly used tests include the Cone Calorimeter Test, Flame Spread Test, and Smoke Density Test. These methods evaluate parameters like ignition time, flame spread rate, and smoke production to classify EPS materials into different fire resistance levels.

Fire safety is paramount for building materials, and for Expanded Polystyrene (EPS), this is determined through specific, standardized tests. These tests don’t just assess if the material burns; they also measure how it burns, which provides a critical “reaction to fire” profile.

Step 1: Specimen Preparation

First, a sample of the EPS material is cut to precise dimensions according to the testing standard, such as the widely used ASTM E84. The specimens must be properly conditioned to a specific temperature and humidity level to ensure consistent and accurate test results, which can be affected by moisture content.

Step 2: The Steiner Tunnel Test

The prepared specimen is placed in a long, rectangular tunnel, known as a Steiner Tunnel. A controlled gas flame is then applied to one end of the specimen. Over a 10-minute period, observers monitor and record the distance the flame spreads along the surface of the material.

Step 3: Data Collection and Analysis

During the test, instruments measure not only the flame spread but also the amount of smoke produced by the burning material. This data is used to calculate the Flame Spread Index (FSI) and the Smoke Developed Index (SDI). These indices are compared to a non-combustible material (cement board) and a highly combustible one (red oak) to assign a final fire rating, such as Class A, B, or C.

| Standard | Region | Key Aspects |

|---|---|---|

| BS EN 13501-1 BS EN 13501-1 | Europe/UK | Classifies reaction to fire with ratings from A1 to F |

| BS 476 | UK | Includes tests for fire propagation and surface spread of flame |

| ASTM E119 | USA | Assesses the fire resistance of building elements |

| ISO 1182 | International | Determines non-combustibility of building materials |

The Relationship Between EPS Fire Ratings and Fire Performance

The relationship between Expanded Polystyrene fire ratings and actual fire performance is significant in determining the material’s effectiveness in fire scenarios. EPS fire ratings serve as standardized assessments of the material’s fire resistance based on laboratory testing, while fire performance refers to its behavior in real-world fire incidents. Understanding this relationship is crucial for ensuring fire safety in various applications.

Expanded Polystyrene fire ratings are determined through rigorous testing methods established by regulatory bodies. They provide valuable insights into the expected fire behavior of EPS under controlled conditions.

The relationship between EPS fire ratings and fire performance is direct and crucial for safety. The fire rating, determined by standardized tests, quantifies a material’s fire performance, specifically its resistance to flame spread and its smoke production.

A higher fire rating indicates a material’s superior ability to resist ignition and combustion under controlled conditions, thereby reducing fire-related risks.

- Flame Spread Index (FSI): This measures how quickly and far a flame spreads across a material’s surface. A lower FSI means a better fire performance, as the material will not contribute to the rapid spread of fire.

- Smoke Developed Index (SDI): This indicates the amount of smoke a material generates when it burns. A low SDI is critical for safety, as dense smoke can obscure visibility and be toxic, hindering evacuation and firefighting efforts.

| Rating Class | Flame Spread Index (FSI) | Smoke Developed Index (SDI) | Fire Performance |

| Class A | 0-25 | ≤ 450 | Excellent (highest level of fire resistance) |

| Class B | 26-75 | ≤ 450 | Good (moderate fire resistance) |

| Class C | 76-200 | ≤ 450 | Fair (basic fire resistance) |

However, the actual fire performance of EPS may vary based on several factors:

Environmental Conditions:

Real-world fire incidents may involve different environmental factors, such as temperature, humidity, and ventilation, which can influence EPS behavior during a fire.

Installation and Design:

The installation practices and design considerations of EPS in structures or products can impact its fire performance. Proper installation and integration are essential for maximizing fire resistance.

Exposure Time and Severity:

The duration and intensity of exposure to fire can significantly affect EPS performance. Prolonged exposure to high temperatures or severe fire conditions may exceed the capabilities indicated by expanded polystyrene fire ratings.

Compatibility with Adjacent Materials:

The interaction between EPS and other materials nearby during a fire can affect its behavior. Compatibility issues or improper material selection may impact fire spread and severity. Prolonged exposure to high temperatures or severe fire conditions may exceed the capabilities indicated by expanded polystyrene fire ratings.

Maintenance and Ageing:

The condition of EPS over time, including factors such as degradation, wear, and exposure to environmental elements, can influence its fire performance. Regular maintenance and inspection are necessary to ensure continued effectiveness.

Regulatory Compliance:

While Expanded Polystyrene fire ratings are based on standardized testing methods and criteria established by regulatory bodies, compliance with these standards does not guarantee absolute fire safety in all scenarios. Adherence to fire safety standards is essential for assessing expected performance.

The Factors Influencing Expanded Polystyrene Fire Ratings

The fire rating of Expanded Polystyrene (EPS) is not a single, fixed value; rather, it is a complex outcome influenced by a combination of chemical composition, physical properties, and its specific application within a construction assembly. Achieving an acceptable safety standard requires manufacturers and builders to manage several critical factors, primarily related to inhibiting ignition and slowing flame spread.

Understanding these variables is essential for meeting stringent building codes and ensuring the material performs as intended under heat exposure.

Structural design

The fire performance of EPS is also influenced by structural design. For example, in buildings, the design of walls and roofs can affect the speed and extent of flame spread.

Thickness and compression

Thicker and denser EPS generally have higher fire resistance as they provide more insulation and are more resistant to flame erosion.

Environmental conditions

Exposure to moist or humid environments may decrease the fire resistance of EPS. Wet EPS may absorb moisture, leading to decreased fire performance.

Expanded Polystyrene Fire Ratings are influenced by the factors mentioned above. Therefore, when selecting and using EPS, it is necessary to consider these factors comprehensively to ensure its safety performance in fire incidents.

Incorporation of Flame Retardants (FR-Grade):

The most direct factor is the addition of flame-retardant chemicals during manufacturing, creating “FR-Grade” EPS. These additives interfere with the combustion cycle by releasing gases that suppress the flame or by promoting the formation of a protective char layer, which causes the EPS to self-extinguish when the ignition source is removed.

Density and Thickness of the Foam:

Higher density EPS generally means a greater mass of material per volume, and increased thickness means more fuel is available. However, in fire tests, the greater material mass can sometimes delay the material’s total involvement in the fire, as thick foam melts and shrinks away from the heat source.

Protective Coverings and Barriers:

The single most important factor is the encapsulation of the EPS with fire-resistant materials, such as gypsum board or concrete sheathing. These non-combustible barriers prevent direct contact between the flame and the EPS, which delays or prevents the foam from reaching its ignition temperature.

Specific Installation and Assembly:

The final fire rating is for the entire building assembly, not just the EPS itself. Improper installation, exposed edges, or gaps in the thermal barrier (such as those around joints or penetrations) create pathways for oxygen and fire, drastically compromising the overall safety performance.

How to Improve Expanded Polystyrene Fire Ratings

Improving expanded polystyrene fire ratings is essential for meeting building safety regulations and reducing fire risks in construction applications. Through material modification, protective layers, and proper system design, EPS can achieve better fire performance while maintaining insulation efficiency, lightweight structure, and durability. These improvements help EPS products perform more safely in walls, roofs, ceilings, and insulated panel systems.

- Meet Certified Fire Testing Standards – Testing EPS products according to recognized fire standards ensures reliable performance. Certified fire ratings help verify material behavior under fire conditions, guiding builders and designers in selecting compliant EPS solutions for different building applications.

- Use Flame-Retardant Additives – Flame-retardant additives are blended into EPS during production to slow ignition and limit flame spread. These additives help the material self-extinguish when the fire source is removed, improving compliance with fire standards without affecting insulation performance.

- Apply Protective Surface Layers – Adding cement boards, gypsum boards, or metal facings over EPS creates a protective barrier against direct flame exposure. These layers delay heat transfer, reduce fire spread, and enhance overall system fire resistance in wall, roof, and ceiling applications.

- Optimize Panel System Design – Proper joint design, sealing, and installation reduce gaps that allow flames or heat to spread. Well-designed EPS panel systems improve fire performance by limiting oxygen access and maintaining structural integrity during fire exposure.

Fire Rating Requirements of EPS in Different Applications

The applications of Expanded Polystyrene (EPS) dictates the specific fire safety requirements it must meet. A fire rating is rarely for the EPS material alone; rather, it’s for the entire assembly—the foam plus its protective coverings. Codes strictly regulate how EPS is used in construction to ensure safety by requiring low flame-spread ratings and fire-resistant barriers, which vary significantly based on whether the application is internal, external, or structural.

1. Interior Walls, Ceilings, and Floors

Since EPS is a foam plastic, the International Building Code (IBC) generally mandates that it must be separated from the interior of the building by a thermal barrier, typically 1/2 inch gypsum wallboard. This ensures that the EPS doesn’t melt, shrink, or ignite in the early stages of a fire.

- Requirement: The foam plastic component itself must typically have an ASTM E84 Class A or B rating.

- Purpose: The gypsum barrier acts as a fire shield, while the FR-grade EPS limits the contribution of the insulation to a fire if the barrier is breached.

2. Exterior Insulation and Finish Systems (EIFS)

EPS used in exterior wall systems is still considered combustible, requiring system-level fire testing to prevent vertical fire spread.

- Requirement: The entire EIFS assembly, including the adhesive, foam, base coat, and finish coat, must pass large-scale tests (like NFPA 285 in the US). This test assesses the fire propagation of the complete wall assembly, including its ability to resist flames from spreading vertically.

3. Roof Insulation

The fire rating for roof assemblies focuses on both resistance to fire from the exterior (brands or flames landing on the roof) and the potential for a fire inside the building to involve the roof system.

- Requirement: Roof assemblies incorporating EPS generally must achieve a Class A, B, or C rating when tested in accordance with standards like UL 790 (for external fire exposure) and must limit the EPS’s surface burning characteristics to FSI ≤ 75 if exposed to interior fire.

4. Cold Storage and Special Applications

For walk-in coolers, freezers, and other large, refrigerated spaces where EPS is used, codes impose even stricter conditions due to the large volume of foam.

Requirement: The foam must have an FSI ≤ 25 and an DSI ≤ 450 , and must be covered by a non-combustible facing (e.g., metal sheeting) and often requires protection by an automatic sprinkler system in the room.

In the construction industry, EPS is commonly used in insulation boards, concrete forms, and architectural decorations. Fire rating requirements for EPS in construction applications typically adhere to building codes and regulations set by local authorities or international standards organizations.

These standards specify the minimum fire resistance performance criteria that EPS products must meet to ensure safety in buildings. Factors such as flame spread, smoke production, and ignition resistance are evaluated to determine the appropriate fire rating for EPS used in construction.

In packaging applications, EPS is valued for its lightweight and shock-absorbing properties, making it ideal for protecting fragile items during transportation and storage. Fire rating requirements for EPS packaging materials may vary depending on the contents being packaged and the mode of transportation.

Regulatory bodies may impose specific fire safety standards for packaging materials to ensure they meet minimum requirements for fire resistance and safety during transit.

Insulation Applications

EPS is extensively used as an insulation material in residential, commercial, and industrial buildings to improve energy efficiency and indoor comfort. Fire rating requirements for EPS insulation typically focus on its ability to resist ignition, slow down flame spread, and limit smoke production in the event of a fire.

Building codes and standards specify the fire resistance performance criteria that EPS insulation products must meet to ensure compliance and safety in building applications.

How to Choose the Right Fire Rating for EPS Products?

Choosing the right fire rating for Expanded Polystyrene (EPS) products is a critical decision that depends on the specific application, local building codes, and safety requirements. Since EPS is inherently flammable, selecting a product with the appropriate fire-retardant treatment is essential for safety and compliance.

1. Understand the Application

The first step is to consider where the EPS product will be used. Is it for interior wall insulation in a residential building, a structural component of a commercial building, or as a packaging material? The level of fire risk and the potential consequences of a fire will dictate the required fire rating. For example, a high-rise building will have much stricter fire safety regulations than a single-story residential home.

2. Consult Local Building Codes and Regulations

Building codes are the primary source of guidance for fire safety. These regulations, which vary by location and building type, specify the minimum fire performance standards for materials. They often refer to specific testing standards, such as the ASTM E84 in the United States or the Euroclass system in Europe. It is crucial to work with a fire safety expert or a registered building professional to ensure your project’s materials meet all legal requirements.

3. Review the Fire Rating Standards

Familiarize yourself with the key fire rating classifications, such as Class A, B, and C.

- Class A (FSI 0-25) represents the highest level of fire resistance, with minimal flame spread. It is often required for commercial buildings, hospitals, and high-occupancy structures.

- Class B (FSI 26-75) offers good fire resistance and is suitable for many residential and light commercial applications.

- Class C (FSI 76-200) provides a basic level of fire resistance, often used for less critical applications.

By carefully considering the application, adhering to local codes, and understanding the different fire rating classifications, you can choose an EPS product that not only meets your project’s needs but also ensures the highest level of safety.

Innovation in Fire-resistant Expanded Polystyrene (EPS) Materials

Intumescent Coatings:

Intumescent coatings are applied to EPS surfaces to provide passive fire protection. These coatings expand when exposed to heat, forming a thick insulating char layer that slows down flame spread and protects the underlying EPS material from fire damage.

Flame Retardant Additives:

Researchers are developing new flame-retardant additives that can be incorporated into EPS during manufacturing. These additives suppress the combustion process, reduce flame spread, and decrease smoke production, improving the fire resistance of EPS products.

Nanostructured Materials:

Nanostructured materials, such as nanoparticles and nanocomposites, are being explored for their potential to enhance the fire resistance of EPS. These materials can be incorporated into EPS formulations to improve their thermal stability and reduce their flammability.

Hybrid Materials:

Hybrid materials, combining EPS with other fire-resistant materials such as mineral fibers or intumescent agents, are being developed to create composite materials with improved fire performance. These hybrid materials offer enhanced fire resistance while maintaining the lightweight and insulation properties of EPS.

Conclusion

Understanding the fire ratings of Expanded Polystyrene is essential for safe and compliant construction. Flame retardants play a crucial role, working to slow or stop the ignition process and significantly improving the material’s fire performance. This makes EPS a viable and safe choice for a wide range of applications, from building insulation to protective packaging.

The careful selection of flame-retardant EPS is not just about meeting regulations; it’s about ensuring the long-term safety of buildings and their occupants. By choosing products with verified fire ratings, you can have confidence in the material’s ability to perform under fire conditions, offering a critical layer of protection.

For all your wholesale Expanded Polystyrene needs, you can rely on our commitment to quality and safety. We offer a wide range of EPS products with certified fire ratings, ensuring you get materials that meet the highest standards. Visit epsole.com to explore our selection and get a quote today.