Expandable polystyrene (EPS) resin is a versatile plastic material widely used in various industries due to its lightweight, durable, and insulating properties.

Its applications range from packaging and construction to crafting and modeling, making it a critical material in modern manufacturing.

What is Expandable Polystyrene Resin?

Expandable polystyrene resin is a type of plastic produced from styrene monomer. It is a rigid and tough foam that can be molded into a variety of shapes and sizes. EPS is known for its excellent thermal insulation, shock absorbency, and resistance to moisture.

Importance of EPS Resin

Expandable polystyrene (EPS) resin is a highly significant material in modern manufacturing and construction due to its unique properties and versatile applications. Here are some key reasons why EPS resin is important:

Versatility

EPS resin’s versatility is one of its most important attributes. It can be molded into a wide range of shapes and sizes, making it suitable for various applications, from packaging and insulation to crafting and model-making. Its adaptability allows manufacturers to tailor it to specific needs, enhancing its utility across different industries.

Insulation Properties

EPS resin is renowned for its excellent thermal insulation properties. It is commonly used in the construction industry for insulating walls, roofs, and floors. This helps in maintaining energy efficiency in buildings by reducing heat loss in winter and keeping interiors cool in summer, thus contributing to lower energy costs and a reduced environmental footprint.

Lightweight Nature

One of the standout features of EPS resin is its lightweight nature. This makes it an ideal material for packaging, as it does not add significant weight to the products it protects. The lightweight characteristic also simplifies handling and transportation, reducing shipping costs and energy consumption during transit.

Protective Cushioning

In packaging applications, EPS resin provides superior shock absorbency, protecting delicate and fragile items during shipping and handling. Its cushioning properties ensure that products arrive intact, reducing the risk of damage and loss. This reliability makes EPS a preferred choice for packaging electronics, glassware, and other sensitive items.

Moisture Resistance

EPS resin is highly resistant to moisture, which prevents it from deteriorating when exposed to wet conditions. This property is particularly beneficial in the construction industry, where EPS insulation can protect buildings from moisture-related issues like mold and mildew. Its moisture resistance also enhances the durability and longevity of the material in various applications.

Cost-Effectiveness

The production and processing of EPS resin are relatively inexpensive compared to other materials. This cost-effectiveness makes it an attractive option for both manufacturers and consumers. The low cost, combined with its other beneficial properties, ensures that EPS remains a competitive material in the market.

Environmental Considerations

While traditional EPS resin has faced criticism for its environmental impact, ongoing advancements are addressing these concerns. Researchers are developing eco-friendly alternatives and improved recycling techniques to make EPS more sustainable. Innovations in biodegradable and bio-based EPS are emerging, reducing the environmental footprint of this versatile material.

Types of Expandable Polystyrene Resin

Expandable polystyrene (EPS) resin comes in various types, each designed to meet specific needs and applications. Here are the main types of EPS resin:

1. General Purpose EPS

General purpose EPS is the most commonly used type of EPS resin. It is versatile and can be found in a wide range of applications, including:

- Packaging: Used for protecting products during shipping and handling.

- Insulation: Utilized in construction for thermal insulation of buildings.

- Crafting and Modeling: Popular among artists and hobbyists for creating models and crafts.

2. High-Density EPS

High-density EPS is characterized by its greater strength and rigidity compared to general purpose EPS. This type is used in applications where additional durability and structural integrity are required. Key uses include:

- Construction: Employed in insulation boards and panels that need to withstand higher loads.

- Engineering: Used as a lightweight fill material in civil engineering projects, such as road construction and embankments.

- Industrial Packaging: Provides robust protection for heavy or sensitive industrial equipment during transport.

3. Flame Retardant EPS

Flame retardant EPS is treated with special additives to enhance its resistance to fire. This type of EPS is essential in applications where fire safety is a critical concern. Its primary applications are:

- Building and Construction: Used in insulating materials for walls, roofs, and floors to comply with fire safety regulations.

- Public Buildings: Applied in settings such as schools, hospitals, and commercial buildings where fire resistance is mandatory.

- Transportation: Utilized in the automotive and aerospace industries for components that require flame resistance.

4. Graphite-Infused EPS

Graphite-infused EPS contains small particles of graphite, which improve its thermal insulation properties. The graphite reflects radiant heat, significantly enhancing the material’s insulating efficiency. This type of EPS is particularly useful in:

- High-Performance Insulation: Ideal for energy-efficient buildings aiming for higher standards of thermal performance.

- Specialized Packaging: Used in packaging solutions that require superior insulation to protect temperature-sensitive goods.

5. Antistatic EPS

Antistatic EPS is designed to prevent the buildup of static electricity. This type of EPS is particularly important in environments where static discharge could damage sensitive electronic components. Key applications include:

- Electronics Packaging: Ensures the safe transport and storage of electronic devices and components by preventing static damage.

- Cleanroom Environments: Used in packaging and storage solutions within cleanrooms to maintain the integrity of sensitive equipment.

6. Biodegradable EPS

Biodegradable EPS is a newer type of EPS resin designed to address environmental concerns. This type of EPS is made from bio-based materials or incorporates additives that promote biodegradation. Its applications include:

- Eco-Friendly Packaging: Used in packaging solutions where environmental impact is a primary consideration.

- Sustainable Construction: Applied in construction projects aiming for green building certifications and sustainability.

Properties of Expandable Polystyrene Resin

Expandable polystyrene (EPS) resin possesses a range of physical, chemical, and mechanical properties that make it a valuable material in numerous applications. Understanding these properties is crucial for selecting the right type of EPS for specific needs.

Here’s an in-depth look at the key properties of EPS resin:

Physical Properties

Density EPS resin is available in various densities, typically ranging from 10 to 30 kg/m³. The density of EPS affects its strength, thermal insulation properties, and suitability for different applications. Higher density EPS offers greater strength and rigidity, while lower density EPS is lighter and more cost-effective.

Thermal Conductivity One of the standout properties of EPS is its excellent thermal insulation. It has a low thermal conductivity, approximately 0.036 W/m·K, which makes it highly effective in preventing heat transfer. This property is why EPS is extensively used in building insulation, refrigeration, and packaging of temperature-sensitive products.

Moisture Resistance EPS is highly resistant to moisture, which prevents it from absorbing water and helps maintain its insulating properties even in damp conditions. This resistance to moisture also prevents the growth of mold and mildew, making EPS suitable for use in humid environments and construction applications.

Chemical Properties

Chemical Resistance EPS resin exhibits good resistance to a variety of chemicals, including acids and bases. However, it can be dissolved by certain organic solvents, such as acetone and benzene. This chemical resistance ensures that EPS maintains its integrity and performance in various industrial and construction settings where it might come into contact with different substances.

Flammability Standard EPS is flammable, which can be a limitation in some applications. To address this, flame retardant versions of EPS are available. These versions are treated with flame retardant additives that reduce the material’s flammability and make it suitable for use in applications where fire safety is a concern.

Mechanical Properties

Compressive Strength EPS resin has good compressive strength, which varies depending on its density. Compressive strength typically ranges from 70 to 700 kPa. This property is particularly important in applications where the material needs to support loads without deforming, such as in construction and packaging.

Flexural Strength EPS also exhibits good flexural strength, which refers to its ability to resist bending forces. This makes it durable and resilient, suitable for applications where the material must maintain its shape and structural integrity under stress.

Impact Resistance The impact resistance of EPS is a key factor in its use as a protective packaging material. EPS can absorb and dissipate energy from impacts, protecting fragile items from damage during transportation and handling. This property also makes it useful in automotive and sports equipment applications where shock absorption is critical.

Additional Properties

Lightweight Nature One of the most advantageous properties of EPS is its lightweight nature. This makes it easy to handle, transport, and install, reducing labor and shipping costs. Despite its light weight, EPS provides significant strength and durability.

Sound Insulation EPS also offers good sound insulation properties. It can help reduce noise transmission, making it useful in building construction for soundproofing walls and floors.

Recyclability EPS is recyclable, and many regions have facilities that can process EPS waste into new products. This recyclability is increasingly important as industries focus on sustainability and reducing environmental impact.

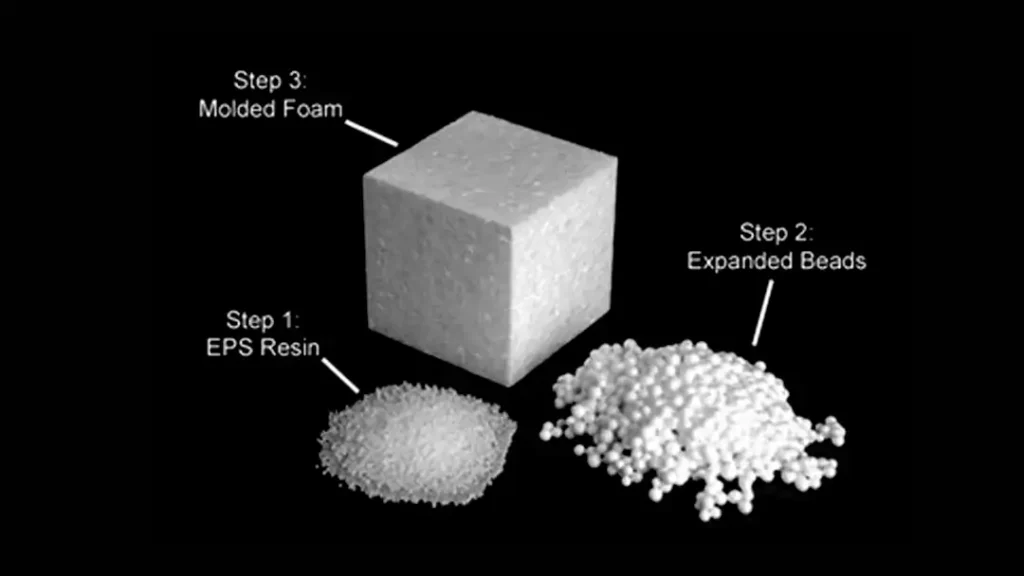

Expandable Polystyrene Resin Manufacturing Process

The manufacturing process of expandable polystyrene (EPS) resin involves several key steps, from the polymerization of styrene monomer to the final molding and cutting of EPS products. Here’s a detailed look at each step:

1. Polymerization

Description: The process begins with the polymerization of styrene monomer, a liquid hydrocarbon derived from petroleum and natural gas by-products.

Details:

- Initiation: The styrene monomer is mixed with an initiator and heated. The initiator starts the polymerization reaction, causing the styrene molecules to link together, forming polystyrene chains.

- Suspension Polymerization: This is the most common method, where styrene is dispersed in water with a stabilizing agent to create tiny droplets. As polymerization proceeds, these droplets solidify into small polystyrene beads.

2. Pre-Expansion

Description: The small polystyrene beads are subjected to steam heat, causing them to expand up to 50 times their original volume.

Details:

- Heating: The beads are heated in a pre-expander using steam. The heat causes the blowing agent (usually pentane) within the beads to vaporize.

- Expansion: As the blowing agent vaporizes, it creates gas bubbles within the beads, causing them to expand significantly. The beads become lightweight and filled with air, transforming into the familiar foam-like structure of EPS.

3. Aging

Description: After pre-expansion, the expanded beads are allowed to age, stabilizing their structure and ensuring uniform expansion.

Details:

- Cooling: The beads are cooled and dried, allowing any residual moisture to evaporate.

- Stabilization: During aging, which typically lasts 24 hours, the expanded beads stabilize in size and density. This step is crucial to achieving consistent quality in the final product.

4. Molding

Description: The expanded and aged beads are then molded into the desired shapes and sizes.

Details:

- Filling: The beads are placed into molds. The molds can be designed to produce blocks, sheets, or custom shapes depending on the intended application.

- Heating and Fusion: Steam is again applied to the mold. The heat causes the beads to soften and fuse together, forming a solid block or shape. The molding process can vary in duration and temperature depending on the size and density required.

5. Cutting and Shaping

Description: The molded EPS blocks or shapes are then cut and shaped into the final products.

Details:

- Cutting: Large blocks of EPS are cut into sheets, panels, or custom shapes using hot wire cutters or CNC (computer numerical control) machines. Hot wire cutters use a heated wire to slice through the EPS smoothly, while CNC machines allow for precise and intricate cuts.

- Shaping: For specific applications, additional shaping processes may be used to create detailed or complex forms.

6. Quality Control

Description: Quality control is conducted throughout the manufacturing process to ensure the EPS products meet required standards and specifications.

Details:

- Inspection: Samples are taken at various stages to check for uniformity in bead size, density, and expansion.

- Testing: Mechanical and thermal properties are tested to ensure the EPS meets industry standards. This includes testing for compressive strength, thermal conductivity, and moisture resistance.

Applications of Expandable Polystyrene Resin

Packaging

EPS is widely used in packaging for its cushioning properties. It protects fragile items during shipping and handling.

Construction

In construction, EPS is used for insulation in walls, roofs, and floors due to its excellent thermal properties.

Crafting and Modeling

Artists and hobbyists use EPS for creating models and crafts because it is easy to shape and manipulate.

Marine Buoys and Floats

EPS’s buoyancy makes it ideal for marine applications such as buoys and flotation devices.

Benefits of Expandable Polystyrene Resin

Expandable polystyrene (EPS) resin offers numerous benefits that make it a popular choice across various industries. Here are some of the key advantages:

1. Lightweight

Description: EPS resin is extremely lightweight, which makes it easy to handle, transport, and install.

Benefits:

- Reduced Shipping Costs: The lightweight nature of EPS significantly reduces transportation costs.

- Ease of Handling: Its light weight makes it easy to handle and install, reducing labor costs and time.

- Fuel Efficiency: Lower weight translates to less fuel consumption during transportation, contributing to environmental sustainability.

2. Excellent Thermal Insulation

Description: EPS resin has outstanding thermal insulation properties, making it an ideal material for insulating buildings and packaging temperature-sensitive products.

Benefits:

- Energy Efficiency: Using EPS for building insulation helps maintain consistent indoor temperatures, reducing the need for heating and cooling and thereby lowering energy bills.

- Temperature Control: EPS packaging keeps temperature-sensitive products, like food and pharmaceuticals, within their required temperature ranges during transport and storage.

- Comfort: Enhanced thermal insulation improves comfort in living and working environments.

3. Shock Absorbency

Description: EPS is known for its excellent shock-absorbing properties, protecting items from impact during transportation.

Benefits:

- Product Protection: EPS packaging protects fragile and delicate items, such as electronics and glassware, from damage during shipping.

- Reduced Returns and Replacements: Effective protection reduces the likelihood of damage, minimizing the costs associated with returns and replacements.

- Safety: In the automotive and sports industries, EPS is used to absorb impacts, enhancing safety in products like car seats and helmets.

4. Moisture Resistance

Description: EPS is highly resistant to moisture, preventing water absorption and protecting against mold and mildew.

Benefits:

- Durability: Moisture resistance ensures that EPS maintains its properties and structural integrity even in damp conditions.

- Mold Prevention: Prevents the growth of mold and mildew, making it ideal for use in humid environments and construction applications.

- Longevity: Extends the lifespan of products made with EPS, reducing the need for frequent replacements.

5. Cost-Effective

Description: EPS resin is relatively inexpensive to produce and process, making it a cost-effective material for a wide range of applications.

Benefits:

- Affordable Packaging: Provides an economical solution for packaging needs, lowering overall costs for manufacturers and consumers.

- Construction Savings: Reduces construction costs when used as insulation or lightweight fill material.

- Cost Efficiency: Balances performance with affordability, offering high value at a low cost.

6. Versatility

Description: EPS can be molded into a variety of shapes and sizes, making it suitable for diverse applications.

Benefits:

- Custom Solutions: Can be customized to meet specific requirements, whether for packaging, construction, or creative projects.

- Wide Range of Applications: Used in industries ranging from packaging and construction to automotive and marine.

- Adaptability: Easily shaped and modified to suit different needs, enhancing its utility.

7. Environmental Benefits

Description: While traditional EPS has faced criticism for its environmental impact, ongoing innovations are making it more sustainable.

Benefits:

- Recyclability: EPS is recyclable, and many facilities can process EPS waste into new products.

- Energy Efficiency: Contributes to energy savings in buildings, reducing overall environmental impact.

- Eco-Friendly Alternatives: New biodegradable and bio-based EPS products are emerging, offering more environmentally friendly options.

Conclusion

Expandable polystyrene resin is a vital material with extensive applications across different sectors. Despite its challenges, ongoing innovations and advancements are paving the way for a more sustainable future. Understanding its properties, benefits, and limitations helps in making informed decisions about its use and management.