Choosing the right insulation panel matters for cost control, energy efficiency, and long-term performance. EPS and PUF panels are two widely used options in cold rooms, warehouses, and industrial buildings. Understanding how they differ helps buyers avoid mismatched materials and unexpected operating expenses later.

This article compares EPS vs PUF panels from multiple angles, including insulation value, structure, installation, durability, and budget considerations. By breaking down real differences instead of marketing claims, you can clearly see which panel fits your project requirements, climate conditions, and usage expectations more accurately.

What are EPS Panels?

EPS panels are insulated sandwich panels made with expanded polystyrene foam as the core material. They are designed to provide thermal insulation, structural support, and lightweight performance.

Commonly used in cold rooms, warehouses, and prefabricated buildings, EPS panels help improve energy efficiency and simplify installation.

EPS Panel Benefits

EPS panels are widely used in construction and cold storage projects because they balance insulation performance, cost control, and installation efficiency. Their stable structure and lightweight design make them suitable for both industrial and commercial applications. Below are the main benefits explained in detail.

- Durability and Moisture Resistance — EPS panels resist moisture absorption and maintain their shape over time. When properly installed and sealed, they perform reliably in humid or cold environments, reducing risks of insulation degradation and helping extend the service life of buildings and cold storage facilities.

- Thermal Insulation Performance — EPS panels provide consistent insulation by reducing heat transfer through walls and roofs. The closed-cell foam structure helps maintain stable indoor temperatures, lowering energy consumption for cooling or heating systems and supporting long-term operational efficiency in controlled environments.

- Lightweight and Easy Installation — The low weight of EPS panels simplifies transportation and on-site handling. This allows faster installation, reduced labor costs, and less structural load on buildings, making them ideal for large-scale projects, renovations, and prefabricated construction where speed and efficiency matter.

- Cost-Effective Solution — Compared with other insulation panels, EPS panels offer a practical balance between performance and price. They help reduce upfront material costs while still delivering dependable insulation, making them attractive for budget-conscious projects without sacrificing basic thermal requirements.

What are PUF Panels?

PUF panels are sandwich panels with a polyurethane foam core, known for excellent thermal insulation and low thermal conductivity.

They are widely used in cold storage, refrigerated warehouses, and industrial buildings. Lightweight yet strong, PUF panels offer quick installation, moisture resistance, and long-lasting performance, making them ideal for projects that require strict temperature control and energy efficiency.

PUF Panel Benefits

PUF panels are popular for cold storage and construction projects due to their superior insulation, durability, and structural strength. They help maintain controlled temperatures efficiently while reducing energy costs. Below are the main benefits of PUF panels explained in detail.

- Moisture and Fire Resistance — Many PUF panels are designed to resist moisture and offer fire-retardant properties. This helps prevent insulation degradation, reduces risks in industrial environments, and ensures safety and longevity in refrigerated or high-humidity spaces.

- Excellent Thermal Insulation — PUF panels have very low thermal conductivity, providing superior insulation. They help maintain stable indoor temperatures, reducing energy consumption for refrigeration or heating systems. This makes them ideal for cold storage, freezers, and temperature-sensitive industrial applications.

- Lightweight and Easy Installation — Despite their strength, PUF panels are lightweight, which simplifies handling, transportation, and installation. Quick assembly reduces labor costs and construction time, making them suitable for prefabricated structures, warehouses, and large-scale projects where efficiency is important.

- Durability and Strength — PUF panels offer strong structural integrity and long-term durability. The foam core resists deformation, while the facings protect against impacts and environmental wear. Properly installed panels maintain performance for years, even under demanding conditions.

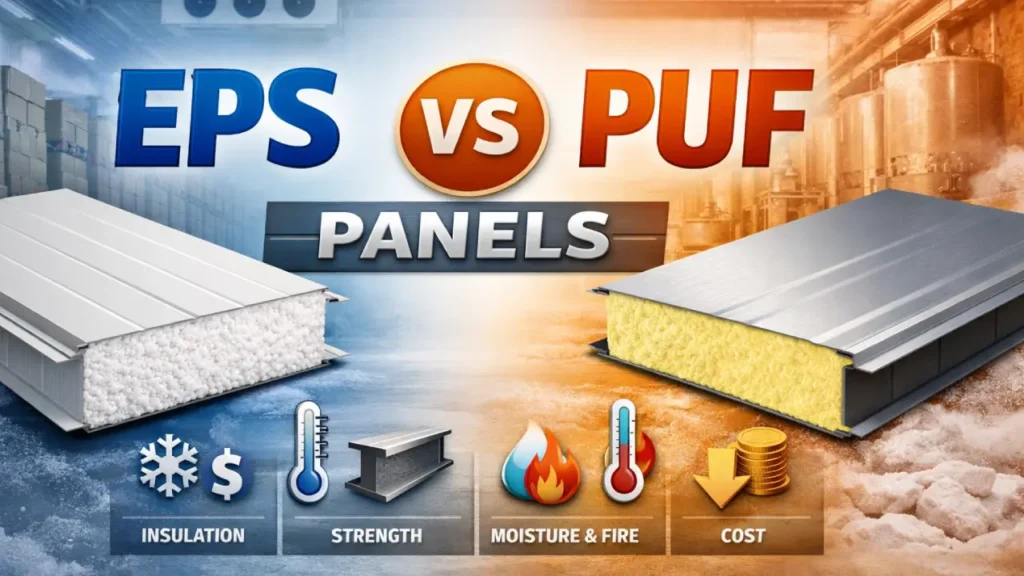

EPS vs PUF Panels

Choosing the right insulation panel is crucial for energy efficiency, cost management, and long-term performance. EPS and PUF panels are widely used in cold storage, warehouses, and industrial buildings, but they differ in insulation, strength, installation, durability, and price. Understanding these differences helps select the most suitable panel for your project.

Thermal Insulation

EPS panels provide good insulation with moderate thermal resistance. They are suitable for standard cold storage and general building applications, keeping temperatures stable without excessive cost.

PUF panels, on the other hand, offer lower thermal conductivity, providing superior insulation for extreme temperature conditions. This makes them ideal for freezers, deep cold storage, and sensitive industrial environments.

Structural Strength

EPS panels are lightweight and provide moderate structural support. They are easy to handle but may require additional reinforcement in heavy-duty applications.

PUF panels are stronger due to the rigid polyurethane core, offering better load-bearing capacity and long-term stability, especially in large-scale industrial or commercial constructions.

Moisture and Fire Resistance

EPS panels resist moisture reasonably well but can absorb water over time if not sealed properly, which may affect insulation performance.

PUF panels are more moisture-resistant and often come with fire-retardant facings, reducing risks of water damage and improving safety in sensitive environments.

Installation and Handling

EPS panels are lightweight and easy to transport, cut, and install, saving labor costs and installation time for moderate-scale projects.

PUF panels are also lightweight but slightly more rigid, requiring careful handling during installation. However, they allow faster assembly in prefabricated and large-scale cold storage projects.

Cost and Availability

EPS panels are generally more cost-effective, making them suitable for budget-conscious projects while still providing reliable insulation.

PUF panels are more expensive due to superior thermal performance and structural strength but can reduce long-term energy costs in extreme conditions.

Here are some differences between EPS and PUF panels:

| Aspect | EPS Panels | PUF Panels |

|---|---|---|

| Thermal Insulation | Moderate thermal resistance | Superior insulation, lower conductivity |

| Structural Strength | Moderate support | High load-bearing capacity |

| Moisture Resistance | Moderate, may absorb water | High, better moisture protection |

| Fire Resistance | Limited, may need additional coating | Often fire-retardant |

| Installation Ease | Lightweight, easy to cut & install | Lightweight, slightly rigid, careful handling |

| Cost | More affordable | Higher upfront cost, energy savings long-term |

How to Choose EPS and PUF Panels?

Choosing the right insulation panels is essential for energy efficiency, cost-effectiveness, and long-term performance. EPS and PUF panels each have strengths, so your decision should consider temperature requirements, installation conditions, budget, and durability. Here are key points to guide your selection.

Application and Usage — Determine the panel’s purpose: cold rooms, warehouses, or industrial buildings. EPS panels are versatile for general applications, while PUF panels are ideal for high-performance refrigeration, industrial storage, or areas with strict thermal control requirements.

Project Temperature Requirements — Consider the operating temperature of your facility. EPS panels are suitable for standard cold storage and moderate temperatures, while PUF panels provide superior insulation for extreme cold conditions, deep freezers, or temperature-sensitive industrial environments. Choosing the right panel ensures consistent performance.

Budget Considerations — EPS panels are generally more cost-effective upfront, making them suitable for projects with tight budgets. PUF panels cost more initially but can reduce long-term energy expenses due to better insulation, making them a wise choice for projects prioritizing energy efficiency.

Installation and Handling — EPS panels are lightweight, easy to cut, and simple to install, reducing labor time and costs. PUF panels are slightly more rigid, requiring careful handling, but they allow faster assembly for prefabricated and large-scale projects with proper planning.

Durability and Maintenance — Evaluate environmental conditions and panel longevity. EPS panels perform well in standard settings but may absorb moisture if not sealed. PUF panels offer stronger structural integrity, higher moisture resistance, and longer service life in demanding environments.

Conclusion

EPS and PUF panels each have clear strengths. PUF panels offer lower thermal conductivity and are often chosen for extreme temperature control. EPS panels stand out for balanced insulation, stable performance, easier handling, and more economical pricing, making them suitable for many commercial and industrial applications worldwide.

From a practical perspective, the right choice depends on project scale, operating temperature, installation speed, and long-term cost planning. Many buyers find EPS panels deliver reliable insulation without excessive material costs, especially for coolrooms, freezers, warehouses, and prefabricated structures with standard thermal demands.

If you are sourcing insulation panels at scale, working with a direct supplier matters. We provide wholesale EPS panels with consistent specifications, flexible sizing, and stable supply for global projects. Contact us to get dependable EPS panel solutions tailored to your cold storage or construction needs.