Importing EPS Sheets from China

Are you still looking for a reliable manufacturer to sell premium EPS sheets with high quality and good performance? Here we can supply the bulk EPS sheets, various in different sizes, lengths, thickness and etc to meet your requirement.

Our EPS Sheets

EPS sheets, or Expanded Polystyrene sheets, are lightweight, rigid, and versatile materials commonly used in various industries for packaging, insulation, construction, and crafting purposes.

- Excellent Insulation: EPS sheets provide superb thermal insulation, helping to maintain consistent temperatures in buildings, refrigeration units, and transportation containers. This property helps reduce energy consumption and costs associated with heating and cooling.

- Lightweight: EPS sheets are lightweight, making them easy to handle and transport. This characteristic is advantageous for applications where weight is a concern, such as in packaging and construction.

- High Strength-to-Weight Ratio: Despite being lightweight, EPS sheets offer excellent strength and durability. They can withstand considerable compressive forces, making them suitable for structural applications in construction and as protective packaging material.

- Shock Absorption: EPS sheets have the ability to absorb impact and distribute it evenly, making them an ideal choice for packaging fragile items. They help protect goods from damage during transportation and handling.

- Moisture Resistance: EPS sheets are inherently resistant to moisture, which prevents them from absorbing water and maintaining their insulation properties even in humid environments. This feature is beneficial for applications where moisture resistance is crucial, such as in insulation and construction.

How to Manufacture EPS Sheets

Manufacturing EPS (Expanded Polystyrene) sheets involves several steps. Here’s a step-by-step guide of the typical EPS sheet manufacturing process:

Step 1: Raw Material Preparation:

- The primary EPS raw material for EPS sheets is polystyrene resin, which is typically in the form of small beads.

- The beads may undergo pre-expansion, where they are exposed to steam to expand them to a larger size. This step improves the moldability of the beads and reduces their density.

Step 2: Molding:

- Expanded polystyrene beads are placed into a mold cavity that corresponds to the desired shape and size of the EPS sheet.

- The mold cavity is then heated, typically using steam, which causes the beads to expand further and fuse together, forming a solid sheet of EPS foam.

Step 3: Cooling and Shaping:

- Once the EPS sheet has been molded by the EPS shape moulding machine, it is cooled rapidly to set its shape.

- Some manufacturing processes may involve additional shaping or cutting steps to trim the sheet to the desired dimensions.

Step 4: Quality Control:

- Quality control checks are conducted to ensure that the EPS sheets meet the required specifications for density, thickness, dimensions, and other properties.

- Any defective or out-of-spec sheets are removed from the production line.

Step 5: Packaging and Storage:

- The finished EPS sheets are packaged and prepared for shipment to customers or storage in inventory.

- Proper packaging helps protect the EPS sheets from damage during transportation and storage.

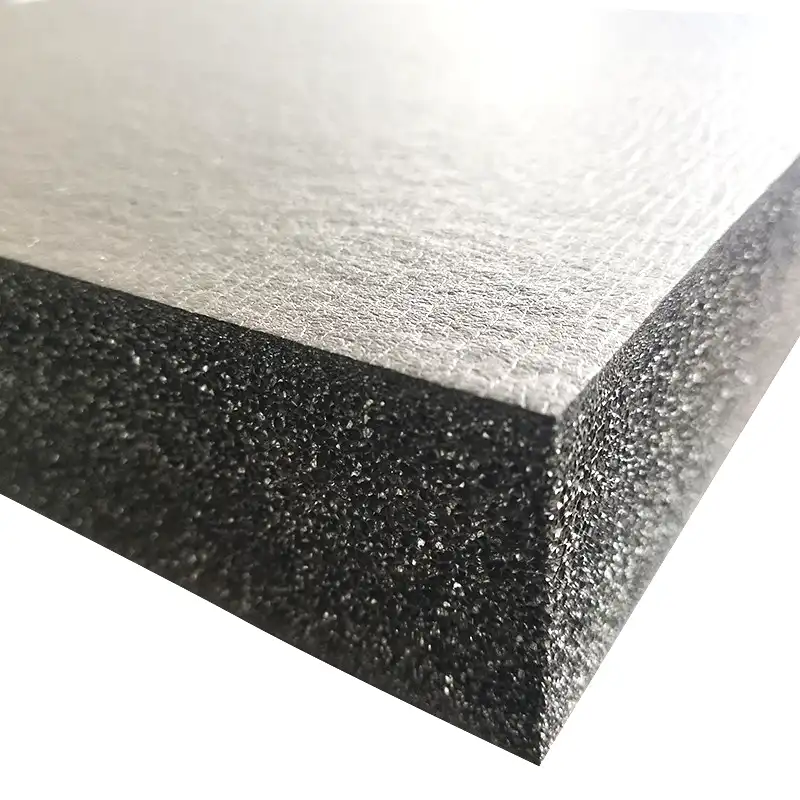

Step 6: Optional Surface Treatment:

- Depending on the intended application, EPS sheets may undergo additional surface treatments or coatings to enhance their properties.

- Surface treatments may include flame retardants, anti-static additives, or coatings for UV resistance and durability.

Step 7: Environmental Considerations:

- Efforts are made to minimize waste and environmental impact throughout the manufacturing process.

- EPS manufacturing facilities may implement recycling programs to manage and reuse waste materials generated during production.

It’s important to note that specific manufacturing processes for EPS sheets may vary depending on factors such as the equipment used, the desired characteristics of the final product, and the requirements of the end-use applications. Additionally, adherence to safety protocols and regulations is essential to ensure worker safety and environmental compliance during EPS sheet manufacturing.

EPS Sheets Applications

EPS (Expanded Polystyrene) sheets find a multitude of applications across various industries due to their versatile properties.

Here’s an overview of some common EPS sheet applications:

Packaging

EPS sheets are extensively used in packaging applications due to their lightweight nature and excellent shock-absorbing properties. They are employed to protect fragile items during shipping and handling, including electronics, glassware, ceramics, and pharmaceuticals.

Insulation

One of the primary applications of EPS sheets is thermal insulation. They are widely used in the construction industry to insulate walls, roofs, floors, and foundations. EPS sheets help maintain indoor temperatures, reduce energy consumption for heating and cooling, and enhance building energy efficiency.

Construction

EPS sheets serve various purposes in construction projects. They are used as formwork for concrete construction, providing temporary molds for pouring concrete in walls, slabs, and columns. EPS sheets are also utilized as lightweight fill material for road embankments, bridge approaches, and landscape grading.

Crafting and Modeling

EPS foam is commonly used in the food service industry for packaging food and beverages, such as foam cups, containers, and trays. EPS recycling machines play a vital role in recycling EPS foam food packaging waste, helping restaurants, cafeterias, and food manufacturers minimize waste and reduce their environmental footprint.

Medical

EPS sheets find applications in the medical industry for cushioning and support. They are used in orthotics and prosthetics for padding and shaping custom-fitted devices. EPS sheets are also employed in medical packaging for transporting and storing sensitive medical equipment and supplies.

Soundproofing

EPS sheets are utilized in soundproofing applications to reduce noise transmission between rooms or buildings. They are installed in walls, ceilings, and floors to absorb and block sound vibrations, improving acoustic comfort in residential, commercial, and industrial spaces.

Why Choose Our EPS Sheets

Superior Insulation: Our EPS sheets provide excellent thermal insulation, helping to maintain consistent indoor temperatures and reduce energy costs for heating and cooling.

Lightweight and Easy to Handle: Our EPS sheets are lightweight, making them easy to transport, handle, and install, saving time and labor costs during construction or packaging operations.

Exceptional Strength and Durability: Despite their lightweight nature, our EPS sheets offer high strength and durability, ensuring reliable performance and long-lasting insulation or protection for your products or structures.

Versatility: Our EPS sheets can be customized to meet specific requirements regarding thickness, density, and dimensions, making them suitable for a wide range of applications across various industries.

Cost-Effectiveness: Choosing our EPS sheets is a cost-effective solution for insulation, packaging, and construction needs. Their affordability and energy-saving properties contribute to overall cost savings over the long term.

Environmentally Friendly: Our EPS sheets are recyclable, contributing to sustainability efforts by reducing waste and minimizing environmental impact. Additionally, EPS is an inert material that does not release harmful chemicals into the environment.

FAQs about EPS Sheets

What are EPS sheets?

EPS sheets are rigid, lightweight panels made from expanded polystyrene foam. They are commonly used for insulation, packaging, construction, and various other applications.

How are EPS sheets manufactured?

EPS sheets are produced by expanding polystyrene beads using steam and pressure, which causes them to fuse and form a closed-cell structure. The resulting foam is then molded into sheets of various thicknesses and densities.

What are the benefits of using EPS sheets?

EPS sheets offer excellent thermal insulation, high strength-to-weight ratio, moisture resistance, shock absorption, and versatility. They are also lightweight, cost-effective, recyclable, and environmentally friendly.

What applications are EPS sheets suitable for?

EPS sheets are used in a wide range of applications, including insulation for buildings, packaging for fragile items, formwork in construction, crafting and modeling, marine flotation, horticultural insulation, and soundproofing.

Are EPS sheets environmentally friendly?

EPS sheets are recyclable and can be reused in various applications, making them environmentally friendly. Additionally, EPS manufacturing processes have become more energy-efficient in recent years, reducing their environmental impact.

How do I choose the right EPS sheets for my project?

When selecting EPS sheets, consider factors such as the desired thickness, density, thermal resistance (R-value), compressive strength, moisture resistance, and compatibility with other materials or systems used in your project.

Are EPS sheets fire-resistant?

While EPS itself is flammable, fire-retardant additives can be incorporated during manufacturing to enhance its fire resistance. It’s essential to check for specific fire ratings and certifications when using EPS sheets in applications where fire safety is a concern.

Can EPS sheets be recycled?

Yes, EPS sheets are recyclable and can be processed into new EPS products or other materials. Many recycling facilities accept EPS for recycling, helping to reduce waste and conserve resources.

How do I install EPS sheets for insulation purposes?

EPS sheets can be installed using various methods, such as adhesive bonding, mechanical fastening, or embedding within other construction materials. It’s essential to follow manufacturer guidelines and industry best practices to ensure proper installation and maximum insulation performance.

Are EPS sheets suitable for outdoor applications?

Yes, EPS sheets are suitable for outdoor use, but they may require protective coatings or treatments to enhance their durability and weather resistance, especially in harsh or exposed environments.