Custom EPS Sandwich Panel from China

Custom EPS sandwich panel from China we offer is manufactured to match specific size, thickness, color, and insulation requirements. We support wall and roof panel applications with stable quality, accurate joints, and reliable delivery. Our solutions suit prefab buildings, warehouses, cold rooms, and commercial projects, helping customers reduce costs and speed up construction.

Get EPS Sandwich Panel Wholesale

Excellent Thermal Insulation – EPS core effectively reduces heat transfer, helping maintain indoor temperature stability, lower energy consumption, and improve overall building comfort.

Lightweight and Strong Structure – The panel combines low weight with good load-bearing capacity, reducing foundation pressure while supporting safe and stable building structures.

Fast and Easy Installation – Prefabricated panels allow quick assembly, shorten construction time, reduce labor requirements, and improve overall project efficiency.

Cost-Effective Building Solution – EPS panels offer affordable materials, low transportation costs, and reduced installation expenses, making them suitable for budget-controlled projects.

Wide Application Range – Suitable for walls, roofs, partitions, warehouses, cold rooms, and temporary buildings across residential and industrial sectors.

EPS sandwich panel production line

Automatic Panel Cutting – The EPS panel production line includes precise cutting systems, ensuring EPS cores and facing materials are cut accurately for consistent panel sizes and reduced material waste.

EPS Core Forming – We use advanced equipment to shape and densify EPS cores, achieving uniform density and optimal thermal insulation properties for each panel.

Lamination Process – EPS cores are bonded with surface materials through high-pressure lamination, creating strong, durable panels that resist moisture, deformation, and environmental stress.

Panel Cooling and Stacking – Finished panels are cooled and stacked efficiently to maintain shape, prevent damage, and prepare them for safe storage or transportation.

Quality Control System – The production line includes inspection stations to monitor panel thickness, density, bonding strength, and surface quality, ensuring consistent performance and customer satisfaction.

Customize Your Desired EPS Sandwich Panel

Panel Size and Thickness Options

We customize panel length, width, and thickness based on building design and insulation needs. By selecting suitable EPS density and steel thickness, we ensure strength, thermal performance, and smooth installation.

Surface Steel and Coating Selection

We offer different steel materials, colors, and coatings to match environmental conditions. By choosing appropriate finishes, we help improve corrosion resistance, durability, and appearance for indoor and outdoor applications.

EPS Density and Insulation Performance

We adjust EPS density to balance insulation, weight, and cost. This customization helps meet specific thermal requirements, energy standards, and climate demands without unnecessary material usage.

Joint Design and Panel Profile

We customize panel joint types and edge profiles for wall or roof applications. Proper joint design improves sealing, installation efficiency, and overall building stability while reducing air leakage.

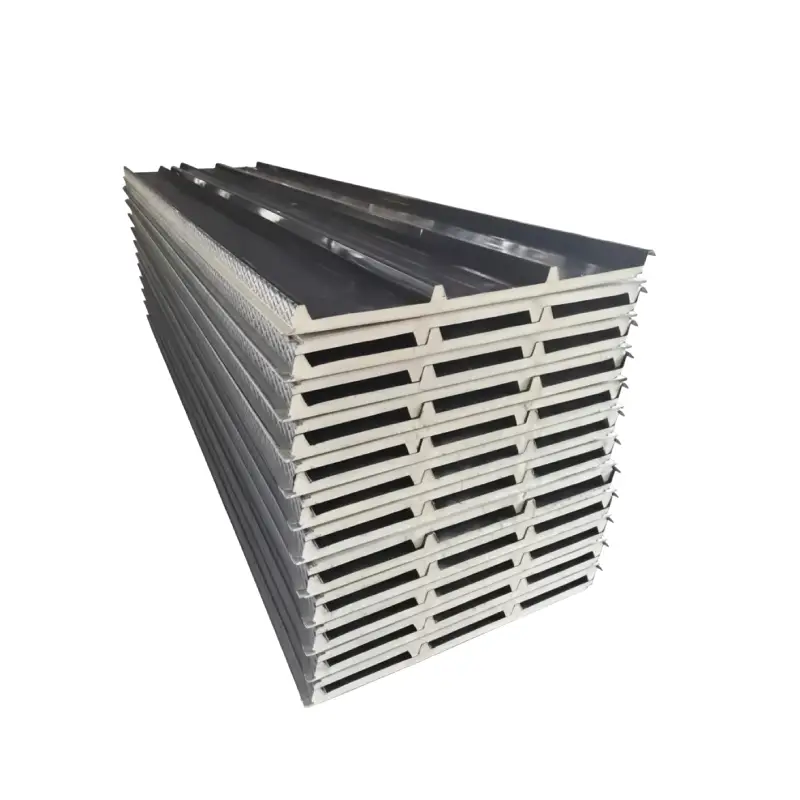

EPS sandwich roof panels

EPS sandwich roof panels we offer are lightweight, well-insulated, and designed for fast installation. They feature strong steel skins and an EPS core that improves thermal performance. Suitable for warehouses, factories, prefab houses, and commercial buildings, our panels provide reliable weather resistance, cost efficiency, and long service life.

EPS sandwich cement panel

EPS sandwich cement panel we offer combines a lightweight EPS core with durable cement boards on both sides. It provides good insulation, fire resistance, and sound reduction. Widely used for interior and exterior walls, partitions, and prefab buildings, it supports fast installation, stable structure, and long service life in residential and commercial projects.

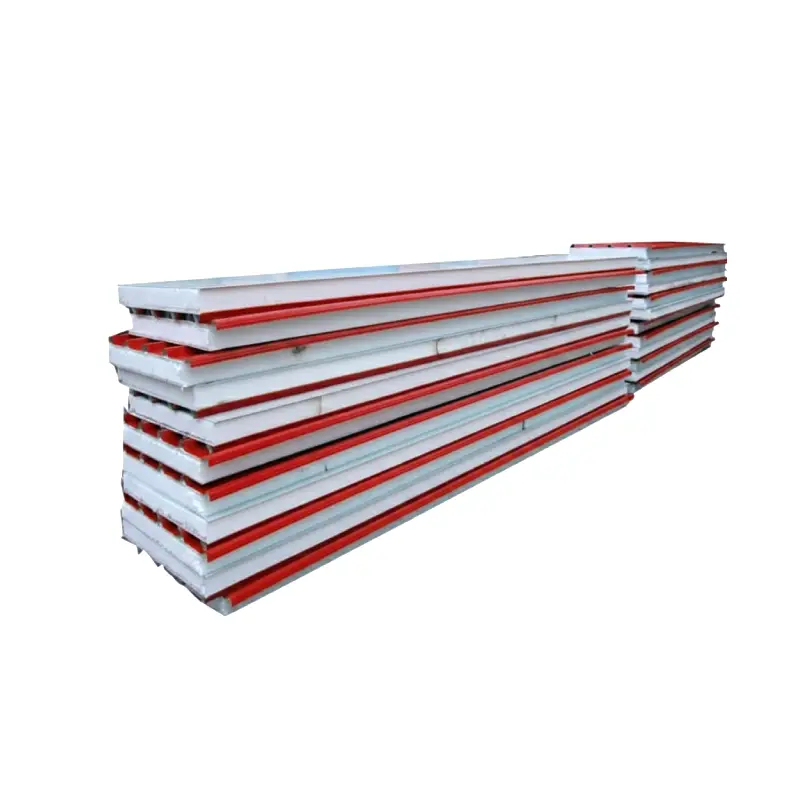

EPS sandwich wall panel

EPS sandwich wall panel we offer provides lightweight structure, reliable thermal insulation, and fast installation for modern buildings. It features a dense EPS core bonded with steel sheets for strength and durability. Widely used in prefab houses, warehouses, factories, and commercial buildings, it helps reduce construction time, control costs, and improve energy efficiency.

EPS concrete sandwich panel

EPS concrete sandwich panel we offer combines reinforced concrete layers with an EPS insulation core for strong load capacity and thermal performance. It is suitable for residential, commercial, and industrial buildings, providing durability, sound insulation, fire resistance, and energy efficiency while supporting fast prefabricated construction and long service life.

EPS insulated sandwich panel

EPS insulated sandwich panel we offer is designed for superior thermal performance and structural strength. Ideal for walls, roofs, and cold storage, it features durable steel surfaces, precise joints, and consistent insulation. We provide panels in various sizes, thicknesses, and colors, ensuring reliable quality and efficient installation for residential, commercial, and industrial projects.

External EPS wall sandwich panels

External EPS wall panels designed for efficient insulation and modern building exteriors. We offer lightweight, durable panels with strong thermal performance, easy installation, and customizable sizes. Ideal for residential, commercial, and industrial projects, our EPS wall panels help reduce energy costs while improving structural efficiency and appearance.

EPS FR insulated panels

EPS FR insulated sandwich panels designed for fire-resistant building applications. We offer lightweight, durable panels with reliable thermal insulation, consistent density, and precise sizing. Suitable for walls, roofs, and industrial projects, our panels support safer construction, easy installation, and stable performance for wholesale and custom supply needs across global markets worldwide.

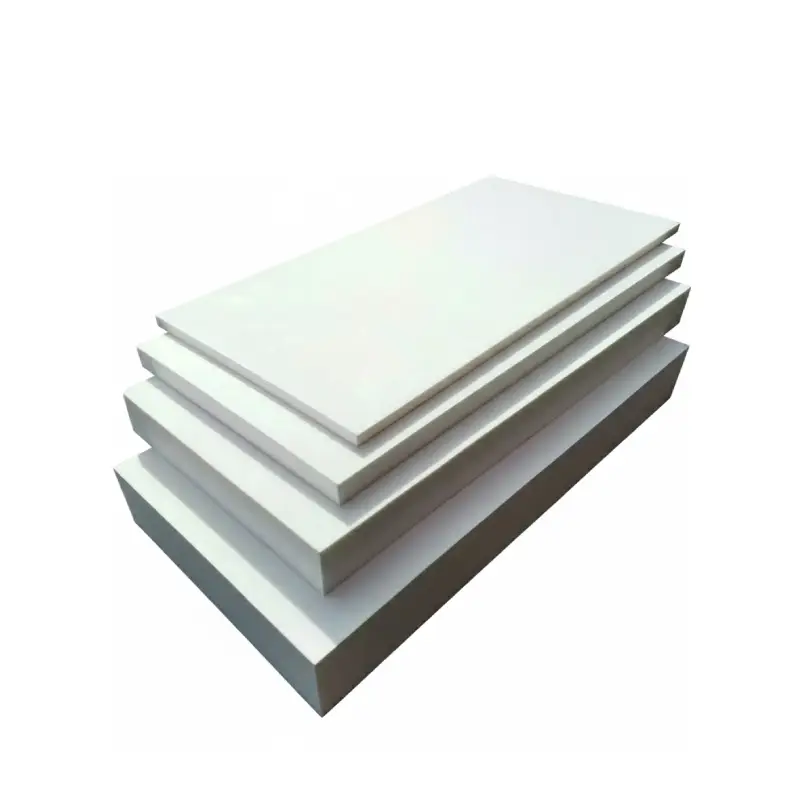

EPS styrofoam Sheet Panels

EPS styrofoam sheet panels we offer are lightweight, durable, and easy to cut, making them ideal for insulation, packaging, and construction uses. Available in custom sizes and densities, they provide reliable thermal performance and cost efficiency for wholesale projects and large-scale applications.

Grooved EPS wall panels

Grooved EPS wall panels we offer are lightweight, easy to install, and designed for insulation and decorative wall systems. The grooved structure improves bonding with mortar or coatings, making them suitable for residential, commercial, and prefabricated buildings. Custom sizes and bulk supply are available for global projects.

durable EPS sandwich panels

Durable EPS sandwich panels designed for superior insulation and strength, we offer a wide range of sizes and finishes to suit construction needs. Lightweight yet robust, these panels enhance energy efficiency, resist moisture and deformation, and provide long-lasting performance for walls, roofs, and cold storage applications, ensuring reliable building solutions.

slim EPS sandwich roof panels

Slim EPS Sandwich Roof Panels designed for energy-efficient buildings. We offer lightweight, durable panels with excellent thermal insulation and weather resistance. Easy to install, they reduce construction time and costs. Ideal for residential, commercial, and industrial roofs. We ensure consistent quality, customizable sizes, and reliable performance for long-lasting roof protection.

EPS Sandwich Panel FAQs

what is EPS sandwich panel?

EPS sandwich panel is a prefabricated building material composed of an expanded polystyrene (EPS) core sandwiched between two steel or aluminum sheets.

It provides excellent thermal insulation, lightweight strength, and quick installation.

Commonly used in walls, roofs, and cold storage facilities, EPS panels enhance energy efficiency, structural stability, and construction speed for residential, commercial, and industrial buildings.

what is EPS sandwich panel made of?

EPS sandwich panel is made of a combination of lightweight insulating core and durable facing materials, designed to provide strength, thermal efficiency, and easy installation.

Its components work together to create panels suitable for walls, roofs, partitions, and cold storage applications in various construction projects.

Expanded Polystyrene (EPS) Core – The EPS foam core provides excellent thermal insulation, lightweight structure, and fire resistance. It maintains dimensional stability, reduces energy consumption, and supports building efficiency, making it ideal for both residential and industrial applications.

Steel Facing Sheets – Galvanized or coated steel sheets on both sides offer structural strength, impact resistance, and durability. They protect the EPS core, ensure long-lasting performance, and provide a smooth surface for interior or exterior finishes.

Adhesive Layer – Strong adhesive bonds the EPS core to the steel sheets, ensuring panel integrity and preventing delamination. It contributes to mechanical stability, reliable joint performance, and consistent insulation properties across the entire panel.

Optional Coatings and Finishes – Panels can include paint, anti-corrosion, or decorative coatings for aesthetic appeal, environmental resistance, and extended service life, allowing customization for different climates, building styles, and functional requirements.

where to use EPS sandwich panels?

EPS sandwich panels are versatile building materials widely used for insulation, structural support, and fast construction. Their lightweight, strong, and thermally efficient design makes them suitable for residential, commercial, and industrial applications, offering energy savings, easy installation, and reliable performance in various climates and project types.

Residential Buildings – EPS panels are used for walls, roofs, and partitions in homes, offering thermal insulation, quick assembly, sound reduction, and durable finishes, improving comfort and energy efficiency while reducing construction time and labor requirements.

Industrial Warehouses – Ideal for large-span warehouse walls and roofs, EPS panels provide insulation, structural support, and protection against weather, helping maintain stable indoor environments and lower energy costs.

Cold Storage Facilities – EPS panels maintain consistent low temperatures for refrigerated storage, reducing energy loss, improving hygiene, and ensuring efficient operation in food processing, pharmaceutical, and logistics sectors.

Commercial Buildings – Offices, shopping centers, and showrooms benefit from EPS panels’ lightweight structure, thermal performance, and fast installation, supporting modern construction aesthetics, energy efficiency, and cost-effective project delivery.

Temporary and Modular Structures – Used in site offices, temporary housing, and mobile units, EPS panels allow rapid construction, relocation, and efficient insulation, providing practical solutions for short-term or flexible building needs.

How to Make EPS sandwich panels?

Making EPS sandwich panels involves combining a lightweight EPS core with durable facing materials to create strong, insulated panels suitable for walls, roofs, and partitions. The process ensures precise dimensions, reliable joint connections, and consistent thermal performance for residential, commercial, and industrial building applications.

EPS Core Preparation – Expanded polystyrene beads are pre-foamed and molded to the desired density and size. This core provides thermal insulation, lightweight strength, and dimensional stability, forming the essential layer of the sandwich panel.

Steel Sheet Selection and Preparation – Galvanized or coated steel sheets are cut, cleaned, and pre-treated for adhesion. These sheets provide structural strength, surface protection, and durability, ensuring the panel withstands environmental and mechanical stress.

Adhesive Application and Layering – A strong adhesive is evenly applied between the EPS core and steel sheets. This step ensures proper bonding, panel integrity, and consistent insulation performance across the panel’s surface.

Pressing and Curing – The layered panel is pressed in a hydraulic or mechanical press to achieve tight adhesion. After curing, it forms a solid, stable sandwich panel ready for cutting, profiling, and installation.

Cutting and Profiling – Panels are trimmed to specified dimensions and edges are profiled for Z-lock or tongue-and-groove joints. This ensures accurate fit, easy assembly, and reliable thermal and structural performance on site.