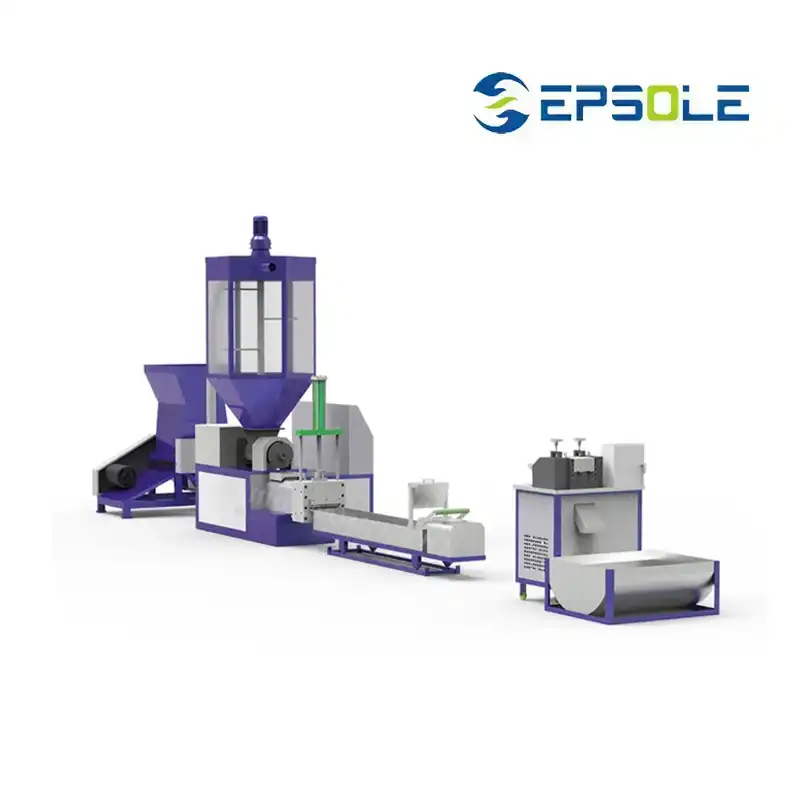

Importing EPS Pelletizing Machine from China

Are you still finding the right EPS pelletizing machine for your project? Epsole is the leading EPS machine manufacturer to provide you the most reliable pelletizing EPS machine to meet your requirement. For more, please feel free to contact us q

Our EPS Foam Recycling Machine

EPS recycling machine is playing a crucial role in reducing waste and promoting sustainability. We can offer the premium EPS recycling machine to meet all of your requirements, here we can provide you all to support EPS recycling machine.

Environmental Sustainability: EPS recycling machines help in reducing the amount of expanded polystyrene (EPS) waste that ends up in landfills or oceans, contributing to a cleaner and healthier environment.

Resource Conservation: By recycling EPS materials, these machines help conserve valuable natural resources such as oil, which is used in the production of virgin EPS, thus promoting sustainability.

Cost Savings: Investing in an EPS recycling machine can lead to significant cost savings for businesses and municipalities by reducing waste disposal costs and potentially generating revenue from selling recycled EPS materials.

Energy Efficiency: Recycling EPS consumes much less energy compared to producing virgin EPS, making it an energy-efficient solution for waste management.

Versatility: EPS recycling machines are capable of processing various forms of EPS waste, including packaging materials, insulation boards, and foam products, making them versatile and adaptable to different recycling needs.

Special Features

Efficient Pelletization

Our machine is equipped with advanced technology for efficiently converting Expanded Polystyrene (EPS) waste into uniform pellets, maximizing output and minimizing waste.

Versatile Processing

Designed to handle a wide range of EPS materials, including packaging waste, insulation boards, and other EPS products, our machine offers versatility in recycling applications.

Energy Efficiency

Incorporating energy-saving features and efficient processing methods, our machine minimizes energy consumption, reducing operational costs and environmental impact.

EPS Pelletizing Machine Applications

Packaging Industry

The recycled EPS pellets produced by our EPS pelletizing machine can be used in the packaging industry to create protective packaging materials for shipping fragile items such as electronics, glassware, and ceramics.

Construction Sector

Recycled EPS pellets are suitable for insulation applications in the construction sector, providing thermal insulation for buildings, homes, and commercial structures. These pellets can also be used as lightweight fill material in construction projects, reducing overall weight and cost.

Marine Conservation

EPS pellets produced by our machine can be used in marine conservation efforts to create artificial reefs or floating barriers for shoreline protection. These structures provide habitats for marine life, prevent coastal erosion, and mitigate the impacts of pollution.

Why Choose Our EPS Pelletizing Machine

-

Superior Performance: Our EPS Pelletizing Machine is engineered with precision and expertise, delivering superior performance in terms of efficiency, output quality, and reliability. With advanced technology and innovative design, it outperforms traditional pelletizing methods, ensuring optimal results every time.

-

Cost-Effectiveness: Investing in our EPS Pelletizing Machine offers long-term cost savings for businesses. By converting EPS waste into valuable pellets, companies can reduce disposal costs, minimize the need for virgin materials, and generate revenue from selling recycled pellets or using them in their own manufacturing processes.

-

Environmental Sustainability: Our Pelletizing Machine plays a crucial role in environmental sustainability efforts by diverting EPS waste from landfills and promoting circular economy principles. By recycling EPS materials into reusable pellets, it reduces resource consumption, minimizes pollution, and helps combat climate change.

-

Versatility and Flexibility: Designed to handle various types of EPS waste and accommodate different recycling needs, our machine offers versatility and flexibility in its applications. Whether it’s packaging waste, insulation boards, or other EPS products, our machine can efficiently process them into high-quality pellets.

-

Energy Efficiency: We prioritize energy efficiency in our machine design, incorporating advanced technologies and optimization techniques to minimize energy consumption during the pelletization process. This not only reduces operational costs but also contributes to sustainability by lowering carbon emissions and environmental impact.

FAQs about EPS Pelletizing Machine

What is an EPS Pelletizing Machine?

An EPS Pelletizing Machine is a specialized equipment designed to recycle Expanded Polystyrene (EPS) waste by converting it into uniform pellets, which can be used as raw material in various industries.

How does an EPS Pelletizing Machine work?

The machine processes EPS waste by shredding, compacting, and extruding the material into small pellets. It typically involves a series of mechanical and thermal processes to compress and reshape the EPS material into pellet form.

What types of EPS waste can be processed by the machine?

Our EPS Pelletizing Machine can handle various types of EPS waste, including packaging materials, insulation boards, foam blocks, and other EPS products commonly used in packaging, construction, and manufacturing industries.

What are the benefits of using an EPS Pelletizing Machine?

Some key benefits include:

- Environmental sustainability: Diverts EPS waste from landfills and promotes recycling.

- Cost-effectiveness: Reduces disposal costs and generates revenue from recycled pellets.

- Resource conservation: Minimizes the need for virgin materials and conserves natural resources.

- Energy efficiency: Optimizes energy consumption during the recycling process.

What maintenance is required for the EPS Pelletizing Machine?

Regular maintenance is essential to ensure the optimal performance and longevity of the machine. This may include cleaning, lubrication, inspection of wear parts, and periodic replacement of components as needed. Our team provides comprehensive support and service to assist with maintenance tasks.