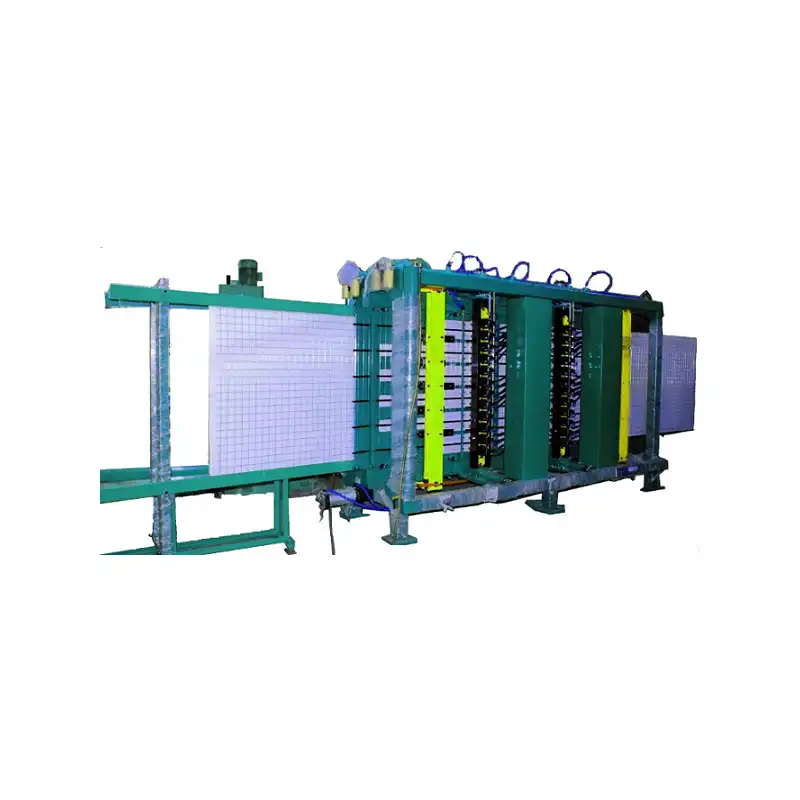

An EPS sandwich panel machine is a specialized manufacturing equipment used to produce sandwich panels, which consist of a core material (such as Expanded Polystyrene – EPS) sandwiched between two outer layers of material (typically steel sheets or aluminum sheets). These panels are widely used in construction for their excellent thermal insulation properties, structural strength, and versatility.

EPS sandwich panel machines are available in various configurations and capacities to accommodate different production requirements. They are often equipped with automation and computerized controls to improve efficiency, accuracy, and consistency in panel production.

Build lighter, stronger, and more energy-efficient structures with this innovative machine. It creates EPS sandwich panels, ideal for walls, roofs, and more, using expanded polystyrene for insulation.

Benefits:

An EPS 3D panel machine is a machine used to produce lightweight, prefabricated building panels consisting of a core of expandable polystyrene (EPS) sandwiched between two welded wire mesh faces.

We are leading EPS manufacturer to provide all-in-one EPS solutions for your EPS project. Welcome to contact us at any time if you are looking for EPS machine, EPS material and many other EPS related product, please feel free to contact us now to get instant help.

Copyright © 2024 Hangzhou Epsole technologies Co.Ltd.

WhatsApp us