Importing EPS Hot Wire Cutting Machine from China

Are you still looking for an EPS hot wire cutting machine for your project? Here we are the leading EPS machine manufacturer to provide you the premium hot wire EPS cutting machine to meet your requirement, and please contact us at any time if you are interested~

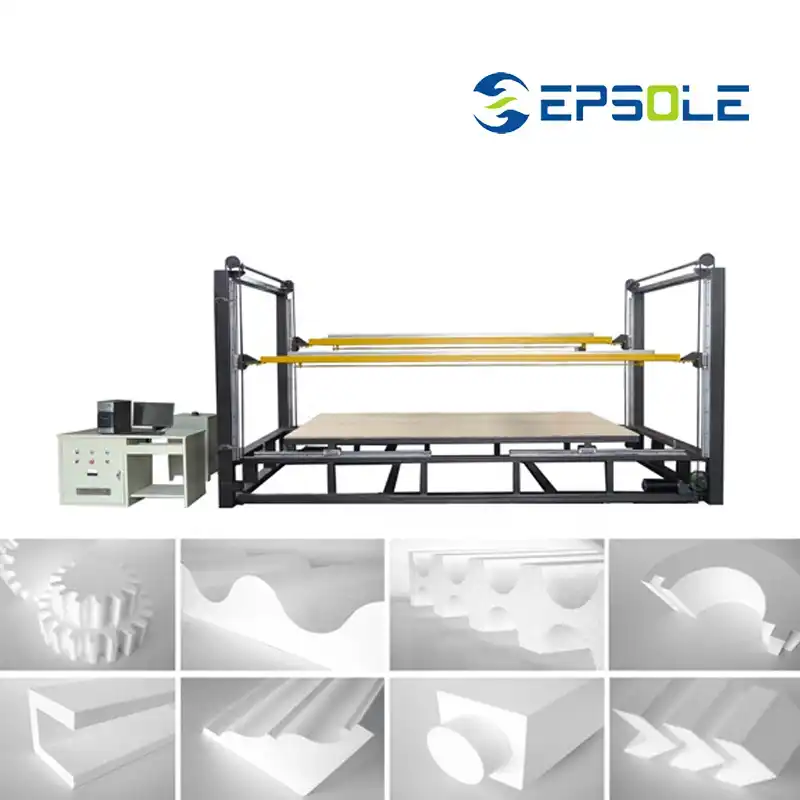

Our EPS Hot Wire Cutting Machine

We have rich experience in manufacturing EPS hot wire foam cutting machine with big capacity, and we can fully control the process from designing EPS hot wire cutting machine to make it in the factory. For more, please feel free to contact us at any time.

Precision Control: EPS hot wire cutting machines offer precise control over cutting parameters such as speed, temperature, and wire tension, ensuring accurate and consistent cuts every time.

Versatility: These machines are capable of cutting a wide range of Expanded Polystyrene (EPS) foam shapes and sizes, making them suitable for various applications including architectural models, packaging, signage, and more.

High-Speed Cutting: EPS hot wire cutting machines are equipped with high-speed cutting capabilities, allowing for efficient production and quick turnaround times, ideal for industrial manufacturing environments.

User-Friendly Interface: Many EPS hot wire cutting machines feature intuitive user interfaces, making them easy to operate even for those with minimal technical expertise. This facilitates smooth workflow and reduces the learning curve for operators.

Customization Options: Advanced EPS hot wire cutting machines often offer customization options such as multi-axis cutting, adjustable wire angles, and interchangeable cutting tools, allowing users to create complex and intricate foam shapes according to their specific requirements.

Special Features

Precise Cutting

EPS hot wire cutting machine is equipped with a heated wire that enables precise cutting of Expanded Polystyrene (EPS) foam materials. This function ensures accurate shaping of foam into desired forms, whether it's for architectural models, packaging inserts, or artistic sculptures.

Adjustable Parameters

Our EPS hot wire cutting machine can you the ability to adjust cutting parameters such as wire temperature, speed, and tension. By customizing these settings, operators can achieve optimal cutting results based on the specific requirements of their projects, ensuring consistency and quality in the final product.

Variable Output Foam

Our EPS hot wire cutting machine can output various shapes, sizes, shapes of foam blocks, inserts, profiles and etc. Flexible for you to cut the foam material to meet your desired shapes as the building material for your construction project.

EPS Hot Wire Cutting Machine Applications

Packaging Industry

EPS hot wire cutting machines are widely used in the packaging industry for creating custom foam inserts and protective packaging solutions for delicate items such as electronics, glassware, and automotive parts.

Architectural Model Making

These machines are essential in the architectural model making process, allowing architects and designers to accurately fabricate scaled models of buildings, landscapes, and urban environments from EPS foam.

Signage and Advertisement

EPS hot wire cutting machines are utilized for crafting large-scale letters, logos, and other custom shapes for outdoor signage, exhibition displays, trade show booths, and advertising installations.

Insulation Manufacturing

In the construction industry, EPS foam is commonly used as insulation material. EPS hot wire cutting machines are employed to cut foam panels and blocks into precise shapes and sizes for insulating walls, roofs, and foundations.

Art and Sculpture

Artists and sculptors use EPS hot wire cutting machines to sculpt intricate shapes and forms from foam blocks, enabling the creation of large-scale sculptures, stage props, theme park decorations, and art installations.

Marine and Aerospace Industry

EPS hot wire cutting machine can be utilized in the marine and aerospace sectors for fabricating lightweight yet durable components such as boat hulls, aircraft wings, and fuselage sections.

Why Choose Our EPS Hot Wire Cutting Machine

Precision Engineering: With our EPS hot wire cutting machine, you can expect unparalleled precision in cutting EPS foam. Whether you’re crafting intricate architectural models or precision packaging inserts, our machine ensures every cut is accurate and consistent.

Versatile Performance: You need a machine that can adapt to your evolving needs. Our EPS hot wire cutting machine offers versatility to handle a wide range of foam densities, thicknesses, and shapes. From simple prototypes to complex sculptures, you can rely on our machine to deliver exceptional results.

Enhanced Productivity: Time is money, and our machine is designed to maximize productivity. With high-speed cutting capabilities and intuitive controls, you can streamline your production process and meet tight deadlines without sacrificing quality.

Durability and Reliability: Investing in a reliable machine is crucial for your business’s success. Our EPS hot wire cutting machine is built to last, with robust construction and premium components that withstand the rigors of continuous use. You can trust our machine to deliver consistent performance day in and day out.

Comprehensive Support: We’re committed to your success every step of the way. From initial setup to ongoing maintenance, our team provides comprehensive support to ensure you get the most out of your investment. Whether you have questions, need training, or require technical assistance, we’re here to help.

FAQs about EPS Hot Wire Cutting Machine

What is an EPS hot wire cutting machine?

An EPS hot wire cutting machine is a specialized tool used to cut Expanded Polystyrene (EPS) foam material with precision using a heated wire. It is commonly employed in industries such as packaging, manufacturing, and construction for shaping foam into various forms and sizes.

How does an EPS hot wire cutting machine work?

The machine consists of a heated wire that is guided through the EPS foam material to create precise cuts. The wire heats up to a specific temperature, allowing it to slice through the foam effortlessly while maintaining accuracy. The machine’s controls enable users to adjust cutting parameters such as temperature, wire tension, and cutting speed.

What types of EPS foam can be cut with these machines?

EPS hot wire cutting machines can cut various types of EPS foam, including standard density foam, high-density foam, and specialty EPS materials with different thicknesses and densities.

What are the advantages of using an EPS hot wire cutting machine?

Some advantages include precise and clean cuts, versatility in shaping foam for different applications, high-speed cutting capabilities, and ease of use with customizable settings. These machines also reduce material waste and enhance production efficiency

What are the common applications of EPS hot wire cutting machines?

These machines are used in industries such as packaging, architectural modeling, signage production, insulation manufacturing, and art and sculpture. They are essential for creating custom foam shapes and designs for various purposes.

Are EPS hot wire cutting machines safe to use?

When operated according to manufacturer instructions and safety guidelines, EPS hot wire cutting machines are safe to use. However, operators should wear appropriate personal protective equipment (PPE) such as gloves and safety glasses to prevent burns and injuries.

Can EPS hot wire cutting machines be automated?

Yes, some EPS hot wire cutting machines can be integrated with automation systems to streamline production processes and increase efficiency. Automated systems may include computer numerical control (CNC) programming for precise cutting and robotic handling of foam materials.