Importing EPS Foam Cornice Machine from China

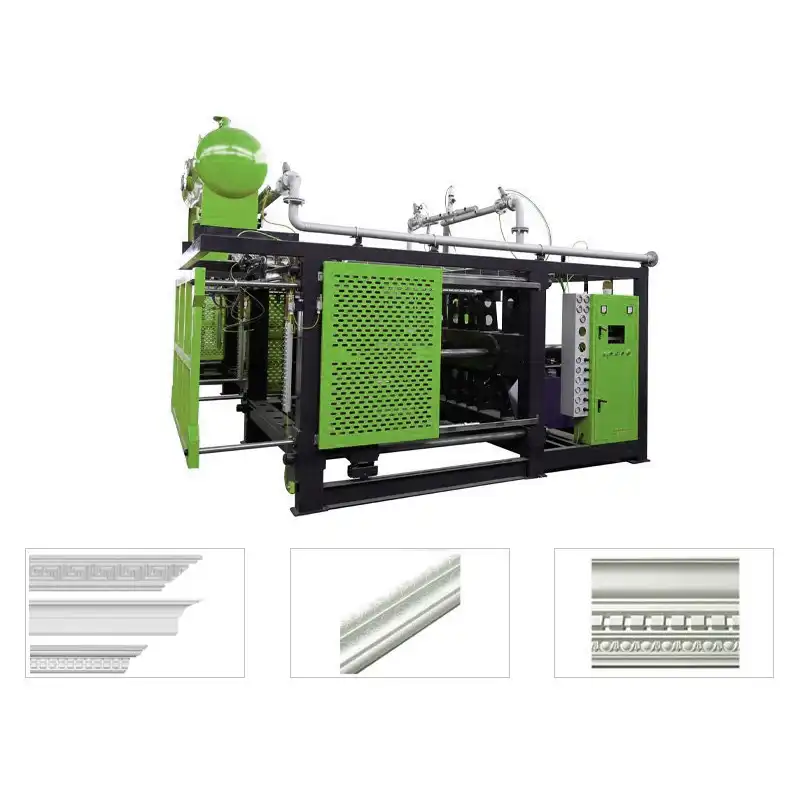

Elevate your architectural solutions with our state-of-the-art EPS foam cornice machine, designed for precision, efficiency, and durability. Our EPS foam cornice machine streamlines the production of high-quality cornices, ensuring consistent results that meet your clients’ demands.

Why Choose Our EPS Foam Cornice Machine

Here are some reasons why you can choose our EPS foam cornice moulding machine to start your EPS cornice production line, and we can customize your desired EPS cornice moulding machine to meet your requirement.

Superior Precision and Quality

Our EPS foam cornice machine is engineered to deliver exceptional precision, ensuring every piece meets the highest quality standards. This results in flawless, professional-grade cornices that will satisfy even the most discerning clients.

Enhanced Efficiency and Productivity

Designed for optimal performance, our machine significantly boosts your production speed while maintaining consistency. This allows you to fulfill large orders promptly, improving overall business efficiency and customer satisfaction.

Durable and Reliable

Built with top-quality materials and advanced technology, our EPS foam cornice machine is both durable and reliable. It’s designed to withstand continuous use, minimizing downtime and maintenance costs.

User-Friendly Operation

Featuring an intuitive interface and easy-to-use controls, our machine requires minimal training for your staff. This ensures a smooth integration into your production line and quick adaptation by your team.

Customizable Solutions

We understand that every business has unique needs. Our machine offers customizable options to cater to your specific requirements, ensuring you get the perfect solution for your production goals.

Competitive Pricing

Invest in a high-quality EPS foam cornice machine without breaking the bank. Our competitive pricing ensures you get the best value for your money, making it a smart investment for your business

Transform your architectural manufacturing with our advanced EPS cornice production line. This complete system is designed for the efficient and precise creation of high-quality EPS cornices, ensuring consistency and excellence in every piece.

- Precision and Quality: Advanced cutting technology ensures each cornice is produced to exact specifications, reducing waste and ensuring high-quality finishes.

- Efficiency: Automation and streamlined processes significantly reduce production time and labor costs.

- Versatility: The production line can handle a variety of designs and sizes, making it suitable for diverse architectural applications.

- Customization: Easily programmable for custom designs, allowing manufacturers to cater to specific client needs.

- Durability: The coating process enhances the durability of the cornices, making them suitable for both interior and exterior applications.

Components of the Production Line:

- EPS Pre-Expander: This machine pre-expands the raw polystyrene beads, controlling the density and ensuring uniform expansion.

- Block Molding Machine: The pre-expanded beads are molded into large EPS blocks, which are the raw material for the cornices.

- EPS Cutting Machine: These machines use hot wires or CNC technology to cut the EPS blocks into the desired cornice shapes and profiles.

- EPS Coating Machine: This applies a protective coating to the EPS cornices, enhancing durability and preparing them for painting or additional finishes.

- EPS Drying and Curing System: Ensures the coated cornices are properly dried and cured, ready for installation or further customization.

Enhance your production capabilities with our EPS cornice production line. Contact us today to learn more, request a quote, or schedule a demonstration!

Here are various EPS foam cornice that our EPS cornice moulding machine can produce, you can use the well-designed EPS foam cornice machine to work out the best EPS foam profiles, shapes for your building project.

EPS Cornice Profiles

Discover our premium EPS cornice profiles, expertly crafted for superior aesthetic appeal and durability. Perfect for both interior and exterior applications, these profiles offer an elegant and cost-effective solution for enhancing architectural details. Lightweight yet robust, our EPS cornice profiles are easy to install and provide long-lasting performance. Upgrade your design projects with our versatile range of styles and sizes. Contact us today to place an order or request a catalog!

EPS Cornice Moulding

Explore our high-quality EPS cornice moulding, designed to add a touch of elegance to any architectural project. Made from durable expanded polystyrene, our moulding offers the perfect blend of strength and lightweight convenience, making installation easy and efficient. Ideal for both residential and commercial applications, our EPS cornice moulding provides a sophisticated finish that stands the test of time. Transform your spaces with our versatile designs. Contact us now to learn more and get a quote!

FAQs about EPS Foam Cornice Machine

What is an EPS foam cornice machine?

An EPS foam cornice machine is a specialized equipment used to manufacture decorative cornices from expanded polystyrene (EPS). These machines ensure precise cutting and shaping of the cornices, allowing for consistent and high-quality production.

What are the benefits of using an EPS foam cornice machine?

The benefits include:

- High precision and consistency in production

- Increased efficiency and reduced labor costs

- Ability to produce a variety of designs and sizes

- Lightweight and durable final products

- Environmentally friendly as EPS is recyclable

What materials can the machine handle?

The EPS foam cornice moulding machine is specifically designed to handle expanded polystyrene (EPS) foam.

Is EPS foam cornice machine easy to operate?

Yes, our EPS foam cornice machines are user-friendly with intuitive controls and comprehensive training provided for your staff.

What maintenance is required for the machine?

Regular maintenance includes cleaning the EPS foam cornice moulding machine, checking for wear and tear on parts, and ensuring the cutting components are sharp and properly aligned. Detailed maintenance instructions are provided with the machine.

How can I order an EPS foam cornice machine?

We can customize the premium EPS foam cornice machine to support you produce various types of EPS foam cornice for your building project, and please feel free to contact us at any time.