Expanded Polystyrene (EPS) is a popular material used in various applications such as packaging, insulation, and construction due to its lightweight, thermal insulation properties, and versatility. However, one of the significant concerns with EPS is its flammability.

To mitigate this risk, EPS can be treated with flame retardants. This guide provides an in-depth look at EPS flame retardants, including their types, mechanisms, applications, and safety considerations.

What is EPS Flame Retardant

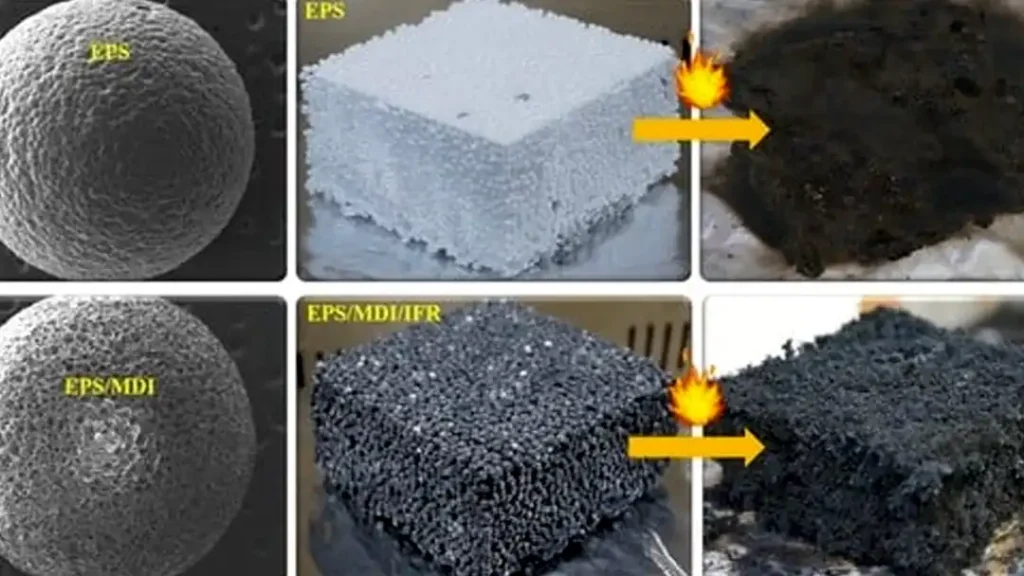

EPS is a type of foam plastic material produced from polystyrene beads that expand when exposed to heat. While beneficial in many ways, untreated EPS can ignite easily and burn rapidly, which poses a fire hazard in various applications.

Flame retardants are chemicals added to materials to inhibit or resist the spread of fire. In EPS, flame retardants work by interfering with the combustion process, thereby enhancing fire safety.

Types of Flame Retardants for EPS

Expanded Polystyrene (EPS) is a flammable material that requires flame retardants to enhance its fire resistance. Various types of flame retardants can be used in EPS, each with distinct chemical compositions and mechanisms for inhibiting fire. These can be broadly categorized into halogenated and non-halogenated flame retardants.

1. Halogenated Flame Retardants

Halogenated flame retardants are compounds that contain halogens (typically bromine or chlorine). These are highly effective in preventing fires but have raised environmental and health concerns due to their persistence and potential toxicity.

Examples:

- Hexabromocyclododecane (HBCD): Historically the most common flame retardant for EPS. HBCD works by releasing bromine radicals that interfere with the combustion process. However, due to its persistence, bioaccumulation, and toxicity, its use has been restricted or banned in many regions.

Mechanism:

- Gas Phase Inhibition: During combustion, halogenated flame retardants release halogen radicals that quench free radicals in the flame, thus interrupting the combustion cycle.

2. Non-Halogenated Flame Retardants

Due to the environmental and health issues associated with halogenated flame retardants, there is a significant shift towards non-halogenated alternatives. These flame retardants are designed to be less harmful to the environment and human health.

Types:

- Phosphorus-based Flame Retardants:

- Examples: Ammonium polyphosphate (APP), Red phosphorus.

- Mechanism: These retardants promote charring, which forms a protective barrier on the material’s surface, preventing heat and oxygen from reaching the underlying material. They can also facilitate the formation of a foam layer that further insulates the material.

- Inorganic Flame Retardants:

- Examples: Aluminum hydroxide (Al(OH)₃), Magnesium hydroxide (Mg(OH)₂).

- Mechanism: These materials decompose endothermically, absorbing heat and releasing water vapor. The released water vapor dilutes flammable gases and cools the material, slowing down the combustion process.

- Nitrogen-based Flame Retardants:

- Examples: Melamine and its derivatives.

- Mechanism: Nitrogen-based retardants decompose to form inert gases like nitrogen and ammonia, which dilute flammable gases and create a physical barrier against the flame.

3. Synergistic Mixtures

To enhance fire retardancy, synergistic mixtures of flame retardants are often used. These mixtures combine different types of flame retardants to leverage their respective strengths.

Examples:

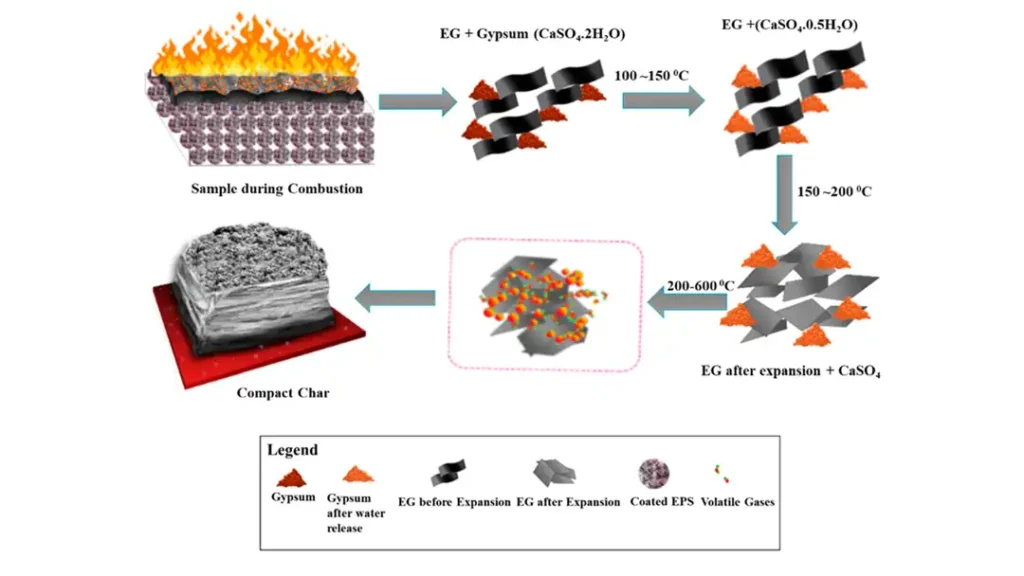

- Intumescent Systems: Combine phosphorus-based and nitrogen-based retardants. When exposed to heat, these systems expand to form a char layer that insulates the material and protects it from further burning.

- Metal Hydroxides and Phosphorus Compounds: Mixing aluminum hydroxide with ammonium polyphosphate can provide both cooling (from the metal hydroxide) and char formation (from the phosphorus compound).

Mechanisms of Flame Retardants

Flame retardants are chemicals designed to inhibit or slow down the spread of fire by suppressing combustion or delaying ignition. They are used in various materials such as textiles, plastics, foams, and electronics to enhance fire safety.

There are several mechanisms through which flame retardants work:

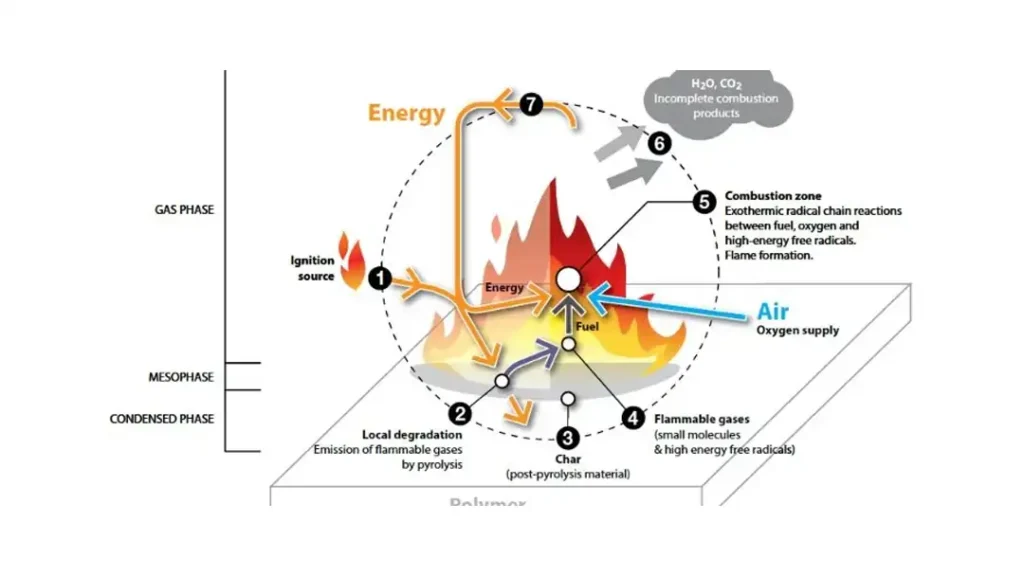

- Gas Phase Inhibition: Some flame retardants release gases when exposed to heat, which can dilute the flammable gases produced during combustion. These gases can interfere with the chemical reactions involved in combustion, thus reducing the flame’s intensity and rate of spread.

- Condensed Phase Actions: Flame retardants can also act in the condensed phase, either by forming a protective layer on the material’s surface or by promoting the formation of char. This char layer acts as a barrier, insulating the underlying material from the heat of the fire and reducing its ability to ignite or sustain combustion.

- Free Radical Scavenging: Certain flame retardants can interrupt the combustion process by scavenging free radicals, which are highly reactive species involved in the chain reactions of combustion. By capturing these radicals, flame retardants can effectively halt the propagation of the fire.

- Endothermic Reactions: Some flame retardants undergo endothermic reactions when exposed to heat, absorbing energy from the surrounding environment. This can lower the temperature of the material, making it less susceptible to ignition or reducing the intensity of the flame.

- Catalytic Effects: Certain flame retardants act as catalysts, promoting reactions that extinguish the flame or inhibit combustion. These catalysts can accelerate the decomposition of flammable molecules or promote the formation of non-combustible products.

- Phosphorus and Nitrogen Synergy: Flame retardants containing phosphorus and nitrogen atoms can work synergistically to enhance fire resistance. Phosphorus compounds can promote char formation, while nitrogen compounds can dilute flammable gases and inhibit combustion reactions.

- Halogenation: Historically, halogen-based flame retardants were widely used due to their effectiveness. These compounds release halogen radicals when exposed to heat, which can interrupt combustion reactions by scavenging radicals or inhibiting the chain reactions of combustion.

Applications of Flame-Retardant EPS

Expanded Polystyrene (EPS) is a lightweight, rigid, and versatile foam material commonly used in various applications. When treated with flame retardants, EPS becomes more resistant to fire, making it suitable for applications where fire safety is a concern. Here are some key applications of flame-retardant EPS:

Building and Construction:

- Insulation: Flame-retardant EPS is widely used in building insulation for walls, roofs, and floors. It provides excellent thermal insulation properties while enhancing fire safety in residential, commercial, and industrial buildings.

- Structural Insulated Panels (SIPs): EPS is used as the core material in SIPs, which are prefabricated building components. The flame retardant properties help ensure these panels meet fire safety standards.

- EIFS (Exterior Insulation and Finish Systems): Flame-retardant EPS is used in EIFS to improve the energy efficiency of buildings while providing a fire-resistant exterior cladding.

Packaging:

- Protective Packaging: Flame-retardant EPS is used to protect sensitive and valuable goods during shipping and storage. This includes electronics, appliances, and hazardous materials, where fire resistance is crucial to prevent fire hazards during transportation.

Automotive and Transportation:

- Vehicle Components: Flame-retardant EPS is used in automotive components, such as padding and insulation, to improve safety by reducing the risk of fire in the event of a collision or electrical fault.

- Public Transportation: In trains, buses, and aircraft, flame-retardant EPS is used for insulation and cushioning to meet stringent fire safety regulations and protect passengers.

Consumer Goods:

- Furniture and Bedding: Flame-retardant EPS is used in the production of furniture and mattresses to meet fire safety standards, reducing the risk of fire-related accidents in homes and commercial spaces.

- Toys and Recreational Equipment: Some toys and recreational equipment use flame-retardant EPS to ensure they are safe for use, particularly in products for children.

Industrial Applications:

- Cold Chain Solutions: Flame-retardant EPS is used in the production of insulated containers for transporting temperature-sensitive goods, such as pharmaceuticals and perishable food items. Fire resistance ensures the safety of these high-value products during storage and transport.

- HVAC Systems: EPS is used in heating, ventilation, and air conditioning (HVAC) systems for insulation and soundproofing. Flame-retardant properties help prevent fire spread within HVAC ducts.

Marine and Offshore:

- Buoyancy Aids: Flame-retardant EPS is used in life vests, life rafts, and other buoyancy aids, providing fire resistance in addition to flotation support, which is crucial for safety in marine environments.

- Offshore Platforms: EPS is used for insulation and floatation devices on offshore oil and gas platforms, where fire safety is a critical concern.

Flame-retardant EPS is employed across a wide range of industries due to its combination of lightweight, insulating properties, and enhanced fire safety. This makes it a valuable material for applications where reducing fire risk is essential.

Regulatory Standards and Testing

Flame-retardant EPS must comply with various national and international fire safety standards, such as:

- ASTM E84 (Standard Test Method for Surface Burning Characteristics of Building Materials)

- UL 94 (Standard for Safety of Flammability of Plastic Materials)

- EN 13501-1 (European standard for fire classification of construction products)

These standards involve rigorous testing to assess the flame spread, smoke production, and overall combustibility of materials.

Conclusion

EPS flame retardants play a critical role in enhancing the fire safety of materials used in various industries. Understanding the types, mechanisms, applications, and safety considerations of these flame retardants is essential for making informed decisions about their use. With ongoing advancements and regulatory changes, the future of flame retardants in EPS will continue to evolve towards safer and more sustainable solutions.