Importing EPS Cup Making Machine from China

Are you looking for EPS cup making machine from China? Epsole can provide qualified EPS cup machine for sale, and we can ensure that you can get your desired EPS cup making machine with competitive price for your project.

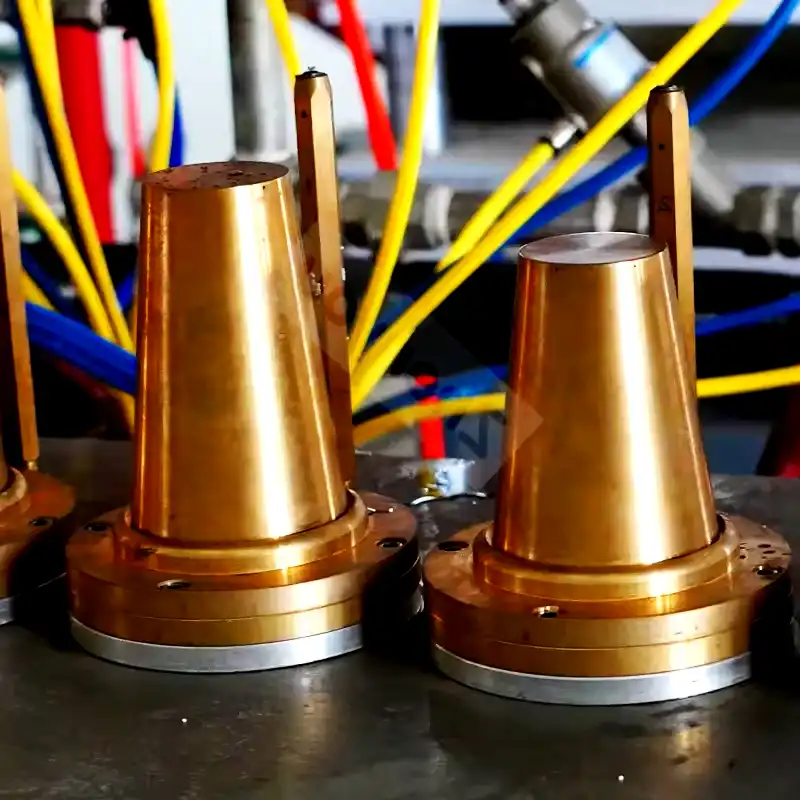

Our EPS Cup Making Machine

Show you our EPS cup making machine! The EPS foam cup making machine is designed to streamline the manufacturing process of EPS foam cups. With its advanced technology and efficient engineering, this EPS cup making machine ensures precise and rapid production of high-quality foam cups.

Precision Engineering: Engineered with precision to ensure accurate shaping and cutting of EPS foam, resulting in consistently high-quality cups.

Automated Operation: Streamline your production process with automated functions that reduce the need for manual labor, improving efficiency and productivity.

Rapid Production: With its high-speed capabilities, this machine can produce a large volume of foam cups in a short amount of time, meeting the demands of your business.

Customizable Settings: Tailor the machine settings to meet your specific production requirements, allowing for flexibility and versatility in cup design and size.

User-Friendly Interface: Intuitive controls and a user-friendly interface make operation simple and straightforward, minimizing the learning curve for operators.

Energy Efficiency: Designed with energy-saving features to reduce operational costs and environmental impact, ensuring sustainability in your manufacturing process.

EPS Cup Making Machine Functions

Foam Injection

Precisely injects expanded polystyrene (EPS) foam material into molds to form cup shapes.

Molding

Shapes the injected foam material into the desired cup form within the molds, ensuring consistency and accuracy.

Cutting

Trims excess foam material and precisely cuts the formed cups to the required size, resulting in uniform cups with clean edges.

EPS Cup Making Machine Applications

Food and Beverage Industry

Used for manufacturing disposable foam cups for hot and cold beverages such as coffee, tea, soft drinks, and juices, providing convenient packaging solutions for restaurants, cafes, fast-food chains, and catering services.

Hospitality Sector

Provides disposable cups for in-room dining, banquets, conferences, and events hosted by hotels, resorts, and convention centers, ensuring hygienic serving options for guests.

Retail and Convenience Stores

Supplies foam cups for takeaway and grab-and-go beverages sold at convenience stores, gas stations, supermarkets, and grocery stores, catering to the needs of on-the-go customers.

Healthcare Facilities

Offers sterile foam cups for dispensing medications, water, and other liquids to patients in hospitals, clinics, nursing homes, and medical facilities, maintaining sanitation standards and facilitating patient care.

Office Environments

Offers disposable cups for coffee stations, break rooms, and meetings in corporate offices, facilitating convenience and cleanliness in workplace refreshment areas.

Airline Catering

Provides foam cups for serving beverages onboard flights, ensuring lightweight and easy-to-handle options for in-flight service.

Why Choose Our EPS Cup Making Machine

Quality Assurance: Our EPS cup making machine is engineered to deliver consistent, high-quality EPS foam cups, meeting stringent standards for durability and reliability.

Efficiency: With advanced automation and precision engineering, our machine ensures optimal production rates, minimizing downtime and maximizing output for enhanced efficiency.

Customization Options: Tailor-made settings allow for flexibility in cup design, size, and thickness, catering to the specific needs and preferences of your business.

Ease of Operation: User-friendly interfaces and intuitive controls make operating our machine simple and hassle-free, reducing the learning curve for operators and enhancing productivity.

Reliability and Durability: Built with robust materials and components, our EPS cup making machine is designed for long-term performance, providing a reliable solution for your manufacturing needs.

Cost-effectiveness: By streamlining production processes and reducing manual labor, our machine helps lower operational costs, offering a cost-effective solution for cup manufacturing.

Technical Support and Service: We provide comprehensive technical support and after-sales service to ensure the smooth operation of our machine, giving you peace of mind and confidence in your investment.

Innovation and Technology: Continuously updated with the latest advancements in technology, our EPS cup making machine represents the forefront of innovation in the industry, keeping your business competitive in the market.

FAQs about EPS Cup Making Machine

What is an EPS cup making machine?

An EPS cup making machine is a specialized piece of equipment designed to produce foam cups from expanded polystyrene (EPS) material. It automates the process of molding, shaping, and cutting foam to create disposable cups used for beverages and other purposes.

How does an EPS cup making machine work?

The machine starts by injecting EPS beads into molds, where they expand and take the shape of the cup. After molding, excess foam is trimmed off, and the formed cups are cut to the desired size. Finally, the cups are stacked and ready for packaging.

What types of cups can be produced with an EPS cup making machine?

EPS cup making machines can produce a variety of cups, including coffee cups, tea cups, soft drink cups, juice cups, and more. These cups can be designed for both hot and cold beverages, depending on the requirements.

What are the advantages of using an EPS cup making machine?

Some advantages include:

- High production efficiency

- Consistent cup quality

- Customizable cup designs and sizes

- Reduced labor costs

- Energy efficiency

- Ease of operation

Is it environmentally friendly to use EPS cups?

While EPS cups are lightweight and have good insulating properties, they are not biodegradable. However, EPS cups can be recycled, and some manufacturers use recycled EPS material to produce new cups, reducing the environmental impact.

What maintenance is required for an EPS cup making machine?

Regular maintenance, such as cleaning and lubricating moving parts, is essential to ensure the smooth operation of the machine. Additionally, periodic inspections and repairs may be necessary to address wear and tear on components.

Can the machine produce cups of different sizes and shapes?

Yes, most EPS cup making machines are capable of producing cups in various sizes and shapes. Settings can be adjusted to accommodate different cup dimensions and designs, providing flexibility for customization.

Is training provided for operating the EPS cup making machine?

Our EPS machine manufacturer can offer training programs or manuals to help starter operators learn how to use the machine effectively and safely. If you have any operation questions, please feel free to contact us at any time.