Importing EPS Coating Machine from China

Are you looking for EPS coating machine? Epsole is the leading EPS machine manufacturer, with big capacity to provide certificated EPS coating machine to make door pocket, window pocket for various buildings. For more, please quote us now to get EPS foam coating machine.

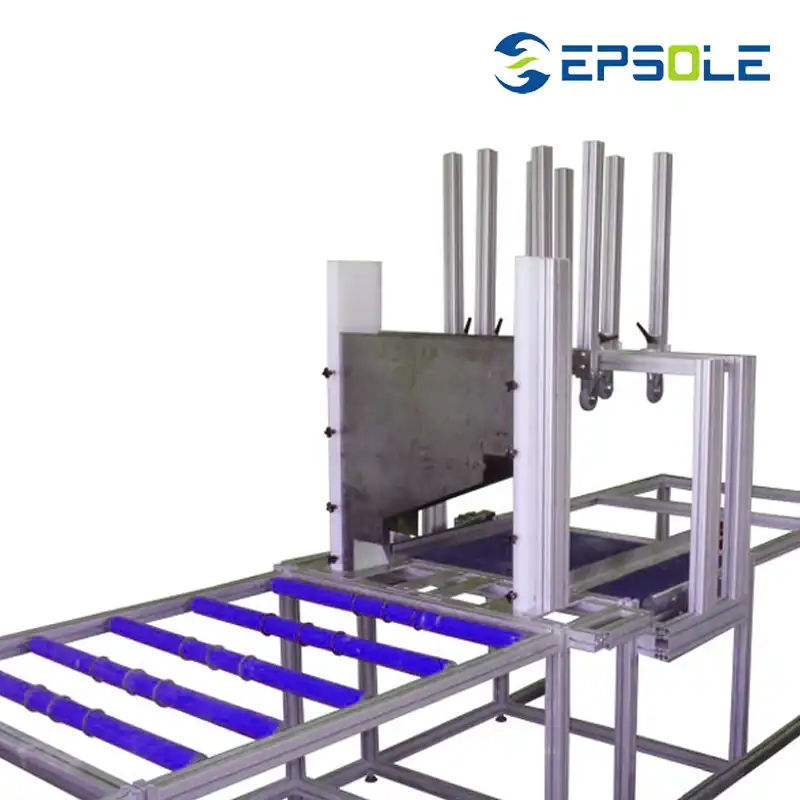

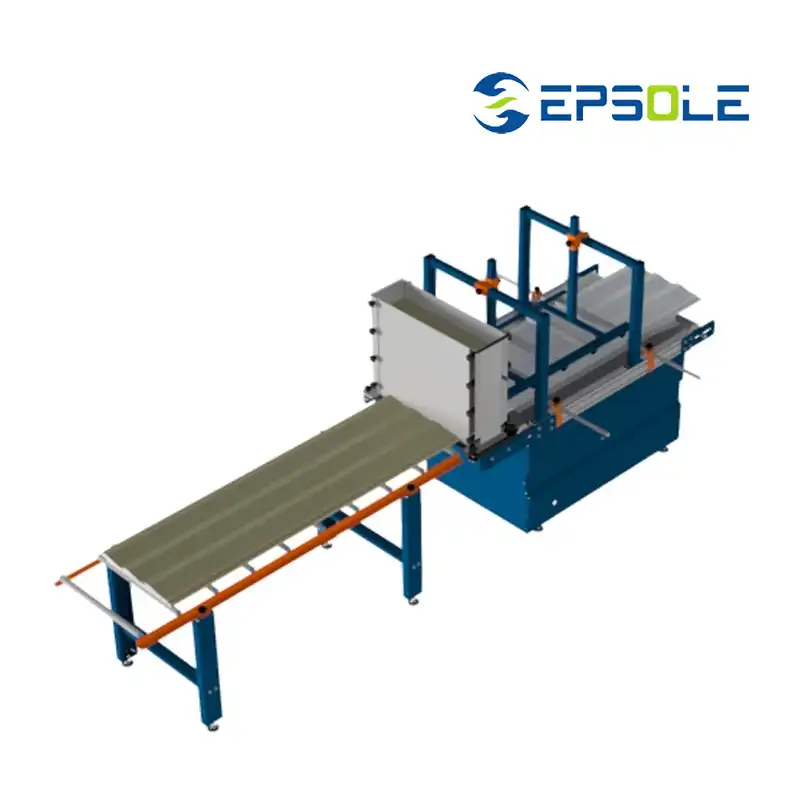

Our EPS Coating Machine

EPS coating machine, also named EPS coating foam machine, is designed to produce the door pocket, window pocket, and cornier for various buildings. For more details, please feel free to contact us now to get your desired EPS coating machine.

-

Precision Control: CNC coating machines offer precise control over coating parameters such as thickness, speed, temperature, and pressure, ensuring consistent and uniform coating application.

-

Automated Operation: These machines are equipped with computer numerical control (CNC) systems, allowing for automated operation with minimal manual intervention. This reduces human error and increases productivity.

-

Versatility: CNC coating machines are capable of applying various types of coatings, including paints, varnishes, adhesives, and protective coatings, on a wide range of substrates such as metal, plastic, wood, and ceramics.

-

Customizable Programs: Users can create and store custom coating programs tailored to specific requirements, allowing for flexibility in production processes.

-

Multi-axis Movement: Many CNC coating machines feature multi-axis movement capabilities, enabling precise control over the positioning of the coating applicator relative to the substrate surface. This facilitates complex coating patterns and designs.

Special Features

Advanced Melting Technology

Many EPS foam recycling machines utilize advanced melting technology to heat and melt the EPS foam waste, facilitating the densification process. This feature helps to reduce the volume of the foam material, making it easier to handle and transport for further processing.

Automatic Sorting System

Some EPS foam recycling machines feature an automatic sorting system that separates EPS foam waste from contaminants such as dirt, debris, and other non-recyclable materials. This helps to ensure that only clean and pure EPS foam material is processed for recycling.

Variable Output Options

EPS foam recycling machines may offer variable output options, allowing users to adjust the density and size of the recycled foam material according to their specific requirements. This flexibility ensures that the machine can accommodate a wide range of recycling needs and applications.

EPS Coating Machine Applications

EPS (Expanded Polystyrene) coating machines find applications in various industries due to their versatility and ability to coat EPS foam with different materials.

Some common applications of EPS coating machines include:

Packaging Industry

EPS coating machines are extensively used in the packaging industry to coat EPS foam with protective layers such as polyethylene, polypropylene, or other materials. Coated EPS foam is commonly utilized in packaging for fragile items, electronics, appliances, and food products.

Construction

In the construction sector, EPS coating machines are employed to apply protective coatings or decorative finishes to EPS foam panels used for insulation, wall cladding, architectural elements, and decorative moldings. These coatings provide enhanced durability, weather resistance, and aesthetic appeal to EPS-based construction materials.

Arts and Crafts

EPS coating machines are utilized in arts and crafts applications for coating EPS foam sculptures, props, set designs, and architectural models. Coatings such as acrylics, latex, or epoxy are applied to EPS foam to create visually appealing and durable surfaces suitable for various artistic and decorative purposes.

Thermal Insulation

EPS foam coating machines are utilized to apply insulating coatings onto EPS foam sheets or panels, enhancing their thermal resistance properties. These coated EPS foam products are commonly used in building insulation systems, refrigeration units, cold storage facilities, and HVAC (Heating, Ventilation, and Air Conditioning) applications to reduce heat transfer and improve energy efficiency.

Acoustic Insulation

EPS coating machines are used to apply sound-absorbing coatings onto EPS foam panels or tiles, enhancing their acoustic insulation properties. Coated EPS foam products find applications in noise reduction barriers, acoustic ceiling panels, recording studios, theaters, and auditoriums to improve sound quality and reduce noise pollution.

Artificial Rockwork and Landscaping

In landscaping and theme park industries, EPS coating machines are utilized to coat EPS foam structures with textured coatings, faux finishes, and weather-resistant sealants to create artificial rockwork, scenic elements, and themed landscapes. Coated EPS foam products are used for constructing rock formations, waterfalls, caves, and themed environments in outdoor parks, zoos, and recreational facilities.

Why Choose Our EPS Coating Machine

-

High Efficiency: Our EPS coating machine is designed for high efficiency, enabling rapid coating application and increased productivity. With advanced automation features and precise control systems, you can optimize your production process and meet demanding deadlines effectively.

-

Versatility: Our EPS coating machine is versatile and capable of handling a wide range of coating materials and substrates. Whether you need to coat EPS foam with protective layers, decorative finishes, or specialized coatings, our machine can accommodate diverse application requirements with ease.

-

Quality Assurance: We prioritize quality assurance in our EPS coating machine, ensuring consistent and uniform coating application across all products. With integrated monitoring systems and customizable settings, you can maintain strict quality standards and deliver superior finished products to your customers.

-

Cost-Effectiveness: Our EPS coating machine offers cost-effective solutions for coating EPS foam compared to manual or traditional coating methods. By streamlining your production process, reducing material waste, and minimizing labor costs, you can enhance your bottom line and improve profitability.

-

Ease of Operation: Our EPS coating machine is user-friendly and easy to operate, even for operators with minimal experience. Intuitive controls, automated features, and comprehensive training support ensure smooth integration into your production environment, minimizing downtime and maximizing uptime.

FAQs about EPS Coating Machine

What is an EPS coating machine?

An EPS coating machine is a specialized equipment used to apply coatings onto Expanded Polystyrene (EPS) foam materials. These machines are designed to coat EPS foam with various materials such as protective layers, decorative finishes, or specialized coatings for different applications.

What types of coatings can be applied using an EPS coating machine?

EPS coating machines can apply a wide range of coatings including polyethylene, polypropylene, paints, varnishes, adhesives, fire-retardant coatings, and other materials suitable for coating EPS foam.

What are the main applications of EPS coating machines?

EPS coating machines are commonly used in industries such as packaging, construction, arts and crafts, advertising, marine, automotive, medical, and entertainment for applications such as packaging, insulation, decoration, prototyping, and fabrication of various products.

How does an EPS coating machine work?

An EPS coating machine typically consists of a conveyor system to move EPS foam through the machine, a coating applicator or spray gun to apply the coating material, and controls to adjust coating parameters such as thickness, speed, and temperature. The machine may also include drying or curing mechanisms to solidify the applied coating.

What are the benefits of using an EPS coating machine?

Using an EPS coating machine offers benefits such as increased efficiency, uniform coating application, versatility in coating materials and substrates, cost-effectiveness, ease of operation, and reliability in production processes.

Can EPS coating machines be customized to specific requirements?

Yes, many EPS coating machines offer customization options to suit specific production requirements. These may include adjustable coating parameters, modular configurations, and compatibility with different coating materials and substrates.

How do I maintain an EPS coating machine?

Proper maintenance of an EPS coating machine involves regular cleaning, lubrication of moving parts, inspection of components for wear and damage, and calibration of controls to ensure accurate coating application. It’s essential to follow the manufacturer’s guidelines and schedule preventive maintenance to keep the machine operating smoothly.

Is training available for operating an EPS coating machine?

Yes, manufacturers typically provide training for operators on how to operate, maintain, and troubleshoot EPS coating machines. Training programs may include hands-on demonstrations, instructional materials, and ongoing support to ensure operators are proficient in using the machine effectively.