EPS Cement Panel Machine

We offer EPS cement panel machines designed for efficient production of durable, lightweight, and insulated cement panels. Our machines combine EPS cores with cement-based facings, producing strong, energy-efficient panels suitable for walls, floors, and roofs in residential, commercial, and industrial buildings, ensuring output and consistent performance.

Why Choose EPS Cement Sandwich Panel Machine

-

Excellent Thermal Insulation – EPS cement sandwich panels provide superior insulation, reducing heat transfer, maintaining comfortable indoor temperatures, and improving energy efficiency in residential, commercial, and industrial buildings.

-

Lightweight and Easy Handling – Despite their strength, these panels are lightweight, simplifying transportation, installation, and handling while reducing structural load and labor requirements on construction sites.

-

Durable and Strong – The cement facing bonded to the EPS core provides high structural integrity, resistance to impact, and long-lasting performance for walls, floors, and roofs.

-

Moisture and Weather Resistant – Panels resist water absorption, corrosion, and environmental wear, ensuring reliable performance and protection against harsh weather conditions in various construction applications.

-

Cost-Effective Construction – Combining insulation, strength, and ease of installation, EPS cement sandwich panels reduce labor, energy, and maintenance costs while supporting efficient, sustainable building projects.

EPS Cement Sandwich Panel Machine Working Process

Step 1: EPS Core Preparation

EPS blocks or beads are expanded using steam to form a uniform, lightweight core that provides thermal insulation and reduces overall panel weight. The density, shape, and moisture content of the core are closely monitored to ensure consistent quality and stability for bonding with cement facings.

Step 2: Cement Slurry Preparation

Cement slurry is mixed with water and additives to achieve proper viscosity, adhesion, and curing properties. Consistent slurry quality ensures strong bonding with the EPS core, smooth panel surfaces, and enhanced resistance to moisture, fire, or other environmental factors. Uniform mixing prevents air pockets and weak points.

Step 3: Laminating and Pressing

The EPS core is sandwiched between cement slurry layers and pressed using a laminating machine. High pressure ensures complete adhesion, eliminates gaps, and forms a strong, durable panel with smooth, uniform surfaces ready for curing. This step directly affects structural integrity and long-term panel performance.

Step 4: Curing

Panels are transferred to curing racks or chambers where temperature and humidity are controlled. Curing strengthens the cement facings, enhances bonding with the EPS core, and ensures dimensional stability, long-term durability, and load-bearing capacity for walls, roofs, and floors. Proper curing prevents cracks and surface defects.

Step 5: Cutting and Sizing

After curing, panels are cut to precise lengths and widths using saws or CNC cutters. Accurate cutting ensures uniform dimensions, reduces material waste, and prepares panels for easy installation, while maintaining the integrity of both the EPS core and cement facings. Edges are trimmed for a clean finish.

Step 6: Quality Inspection and Packaging

Finished panels undergo inspection for thickness, bonding strength, surface quality, and insulation performance. Panels meeting quality standards are stacked and packaged for safe transport and storage, preventing deformation or damage. Rigorous inspection ensures consistent, reliable panels for energy-efficient and durable construction projects.

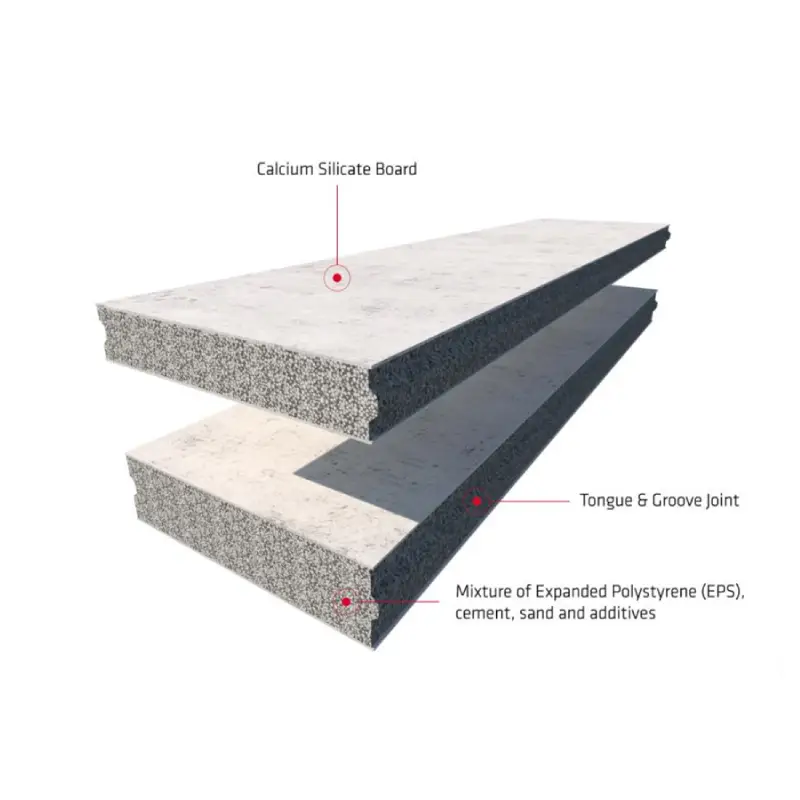

EPS Cement Sandwich Panels

EPS cement panels

We offer EPS cement panels that combine lightweight insulation with durable cement facings for walls, floors, and roofs. Our panels provide excellent thermal performance, structural strength, and moisture resistance, making them ideal for residential, commercial, and industrial buildings. They support fast installation, energy efficiency, and long-lasting construction solutions.

EPS cement sandwich panels

We offer complete solutions for EPS cement sandwich panels, including customized thickness, size, and core density. Our panels support fast installation, long-term durability, and reliable insulation performance. With consistent quality and tailored designs, we help clients achieve efficient, cost-effective construction while meeting project-specific structural, thermal, and aesthetic requirements.

interlock EPS cement panels

We offer interlock EPS cement panels designed for fast, secure, and energy-efficient construction. Featuring a lightweight EPS core with cement facings and precise interlocking edges, our panels provide excellent thermal insulation, structural strength, and moisture resistance. They are ideal for walls, floors, and roofs in residential, commercial, and industrial buildings.

lightweight EPS cement panels

We offer lightweight EPS cement panels that combine thermal insulation with structural strength for efficient construction. Featuring a durable EPS core bonded with cement facings, these panels are easy to handle, transport, and install. They provide energy efficiency, moisture resistance, and long-lasting performance for walls, floors, and roofs.

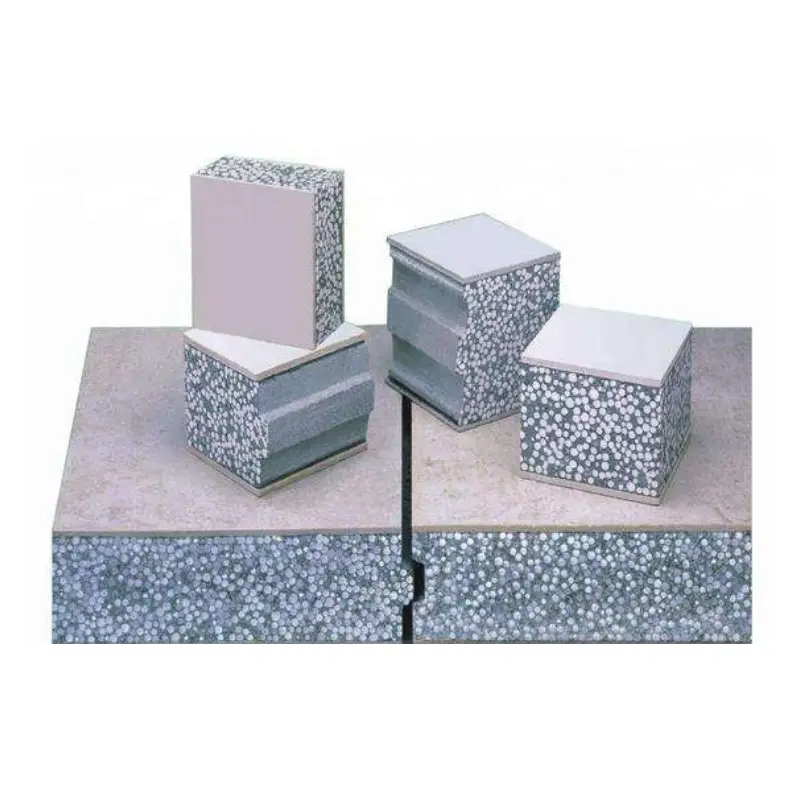

EPS cement panel blocks

We offer EPS cement panel blocks designed for lightweight, strong, and insulated construction. Combining an EPS core with cement facings, these blocks provide excellent thermal performance, durability, and moisture resistance. Ideal for walls, floors, and roofs, they support fast installation, energy efficiency, and long-lasting structural integrity in residential, commercial, and industrial projects.

FAQs about EPS Cement Sandwich Panel Machine

What is an EPS Cement Sandwich Panel machine?

EPS sandwich panels are composite building materials that consist of a core of expanded polystyrene (EPS) foam sandwiched between two outer layers, typically made of pre-painted steel sheets. This construction creates a lightweight yet structurally rigid panel that offers excellent thermal insulation. The EPS core provides the insulation properties, while the steel sheets provide strength, durability, and weather resistance.

These panels are widely used in the construction of walls, roofs, and ceilings in various applications, including industrial buildings, warehouses, cold storage facilities, and prefabricated homes. Their ease of installation, combined with their thermal efficiency and cost-effectiveness, makes them a popular choice in modern construction. They are known for their ability to provide good thermal insulation, and because of the light weight nature of the EPS core, they are easy to install.

What is EPS Sandwich Panel?

An EPS Cement Sandwich Panel Machine is a piece of equipment used for producing lightweight building panels ideal for walls, roofs, and more.

Components of EPS cement sandwich wall panel machine

- Mixing System: Accurately measures and mixes raw materials like cement, fly ash (sometimes), and water to create a consistent cement slurry.

- Molding System: Holds the mixed material and shapes it around an EPS (expanded polystyrene) core. Molds can be adjustable for different panel thicknesses and sizes.

- EPS Feeding System: Dispenses and positions EPS beads precisely within the mold cavity.

- Curing System: Provides controlled pressure and temperature for the panels to solidify properly.

- Demolding System: Safely removes the finished panels from the mold.

What are EPS Cement Sandwich Panels?

EPS Cement Sandwich Panels are lightweight building materials with an EPS (expanded polystyrene) core encased between two layers of cement facings. They offer advantages like good insulation, fire resistance, and ease of construction.

What are the benefits of using an EPS Cement Sandwich Panel Machine?

Faster production compared to manual methods.

Consistent panel quality and reduced waste.

Lower production costs per panel.

Ability to customize panels for various projects.

What are the different types of EPS Cement Sandwich Panel Machines?

There are generally two main types: horizontal EPS cement sandwich panel machine and vertical.

Horizontal machines offer higher automation and require less floor space, while vertical machines can have a higher output but require more manpower.

EPS Cement Sandwich Panel Manufacturing Process

The manufacturing process of EPS cement sandwich panels involves several key stages, each contributing to the panel’s structural integrity and thermal performance.

This process combines the insulating properties of EPS with the strength and durability of cementitious materials, creating a versatile building component.

Step 1: Preparing the EPS Core and Cementitious Layers

The process begins with the preparation of the expanded polystyrene (EPS) core. This involves cutting or shaping the EPS foam to the required dimensions, ensuring a uniform thickness and surface. Simultaneously, the cementitious layers are prepared.

These layers typically consist of a mixture of cement, sand, and additives, which are blended to achieve the desired consistency and strength. The preparation of these materials is crucial for ensuring the panel’s overall quality and performance.

The cementitious mixture is then applied to the outer surfaces of the EPS core. This can be done through spraying, rolling, or pressing, depending on the manufacturing setup. The application process is carefully controlled to ensure a uniform layer thickness and consistent adhesion to the EPS core. The quality of the cementitious layers directly impacts the panel’s structural strength, fire resistance, and weather resistance.

Step 2: Bonding and Pressing the Layers

After the cementitious layers are applied, the panel is subjected to a bonding and pressing process. This involves applying pressure to the panel to ensure a strong bond between the EPS core and the cementitious layers. The pressure is typically applied using a hydraulic press or a continuous lamination line, which ensures uniform compression and adhesion.

The bonding process may also involve the application of heat or adhesives to enhance the bond between the EPS core and the cementitious layers. The specific bonding method depends on the materials used and the desired panel properties. The goal is to create a strong, durable bond that can withstand the stresses and environmental conditions the panel will encounter in its application.

Step 3: Curing and Drying the Panels

Once the layers are bonded, the panels undergo a curing and drying process. This stage is crucial for ensuring the cementitious layers achieve their full strength and durability. The panels are typically placed in a curing chamber or allowed to dry under controlled environmental conditions, such as specific temperature and humidity levels.

The curing process allows the cementitious materials to hydrate and harden, forming a solid, durable outer layer. The duration of the curing and drying process depends on the specific cementitious mixture used and the desired panel properties. Proper curing is essential for preventing cracking, warping, and other defects in the finished panels.

Step 4: Quality Control and Finishing

After curing and drying, the panels undergo a thorough quality control inspection. This involves checking for dimensional accuracy, surface finish, and structural integrity. Any panels that fail to meet the required specifications are rejected or reworked.

The finishing process may include cutting the panels to the desired dimensions, applying surface treatments, or adding edge details. These finishing steps enhance the panel’s appearance, performance, and ease of installation. The finished panels are then packaged and prepared for shipment to construction sites or distribution centers.