Importing EPS Block Cutting Machine from China

Are you looking for an EPS block cutting machine for your project? Epsole is a leading China EPS cutting machine factory. We can manufacture the qualified EPS block cutting machine to meet your requirements, welcome to quote us now to get more details.

Our EPS Block Cutting Machine

EPS cutting machine is widely used in foam cutting industry due to its characteristics of high efficiency and accuracy. It is an important equipment for foam industry. For details about this amazing EPS block cutting machine, please feel free to contact China eps block cutting machine factory.

- Precise Cutting and Trimming: Achieves accurate cuts according to required sizes and shapes.

- Precision Knife Cutting System: Handles foam with densities up to 8 kg/m³ accurately.

- Proficient Specialists: Experts in grinding adjustment ensure desired accuracy.

- Powerful Cutting System: Equipped with precise speed control for smooth and even cuts.

- Adjustable Parameters: Various speed modes and parameters allow precise control for different materials.

EPS Block Cutting Machine Applications

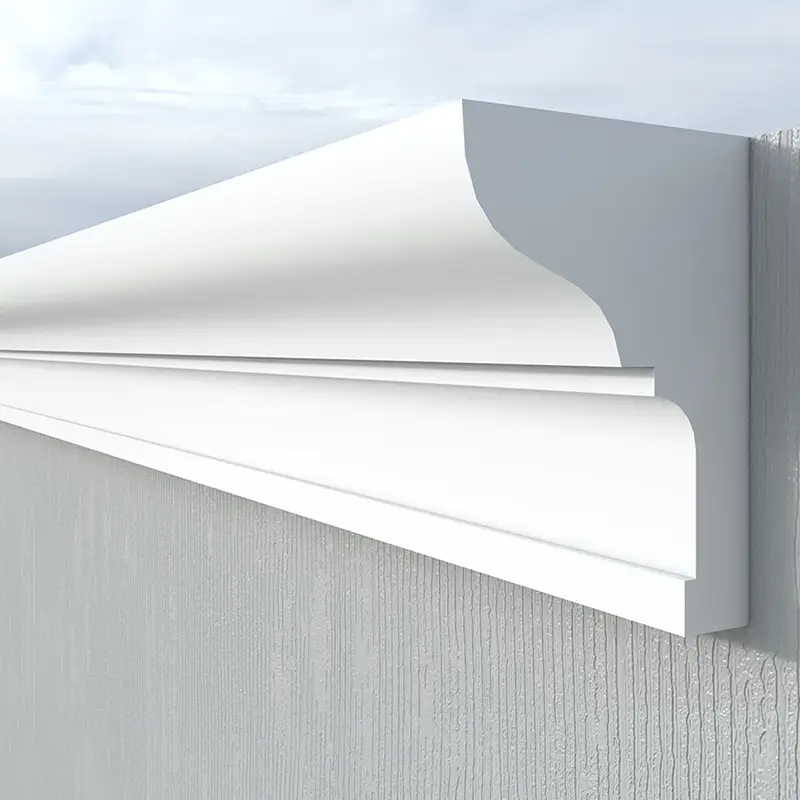

Building material

These machines are vital in construction for fabricating EPS blocks into insulation sheets for walls, roofs, and floors. Their accuracy ensures consistent insulation thickness, enhancing energy efficiency and soundproofing in buildings.

Consumer Product Packaging

EPS block cutting machines are crucial in the packaging industry, shaping expanded polystyrene blocks into custom forms for packaging materials like foam inserts and protective containers. This precision ensures secure transportation and product protection.

Sculptures And Designs

Artists use EPS block cutting machines to carve intricate sculptures and designs. These machines enable precise realization of artistic visions in three dimensions, from large installations to detailed decorative elements, expanding creative possibilities in art and design.

Why Choose Our EPS Block Cutting Machine

- Efficiency: Our EPS block cutting machine is engineered for optimal efficiency, ensuring swift processing of expanded polystyrene (EPS) blocks into precise cuts. With cutting-edge technology and streamlined features, our machine enhances productivity, saving valuable time and resources.

- Versatility: Our EPS block cutting machine is versatile, capable of handling various sizes and shapes of EPS blocks with ease. Whether you need to cut blocks for packaging, insulation, or other applications, our machine delivers consistent and accurate results.

- Quality Output: We prioritize the quality of cut EPS blocks produced by our machine. Through precise cutting mechanisms and top-grade components, we ensure that each cut meets stringent quality standards, providing reliable and uniform blocks for your needs.

- Sustainability: Investing in our EPS block cutting machine reflects your commitment to sustainability. By optimizing block cutting processes, you reduce material waste, promote resource conservation, and support eco-friendly manufacturing practices.

- Support and Service: When you choose our EPS block cutting machine, you benefit from dedicated support and service. Our team of experts assists you with installation, training, maintenance, and troubleshooting, ensuring optimal performance and longevity of your cutting equipment.

FAQs

What is an EPS block cutting machine?

An EPS block cutting machine is a piece of equipment used to cut large blocks of Expanded Polystyrene foam into smaller pieces or specific shapes. It is a crucial component in the manufacturing process of EPS-based products.

What types of cutting methods are used in EPS block cutting machines?

EPS block cutting machines typically use hot wire cutting or saw cutting methods. Hot wire cutting involves heating a wire to high temperatures to slice through the foam, while saw cutting utilizes blades or knives to cut through the material.

What are the key features to consider when choosing an EPS block cutting machine?

Important features to consider include cutting accuracy, cutting speed, blade or wire durability, cutting dimensions (length, width, and thickness), automation capabilities, safety features, and overall reliability.

What are the benefits of using hot wire cutting in EPS block cutting machines?

Hot wire cutting produces clean and precise cuts, and it is particularly suitable for cutting EPS foam due to its ability to slice through the material smoothly without causing deformation or compression.

Can EPS block cutting machines handle different densities and thicknesses of EPS foam?

Yes, EPS block cutting machines are designed to accommodate various densities and thicknesses of EPS foam blocks. However, adjustments may be required to optimize cutting parameters based on the specific characteristics of the foam.

Are EPS block cutting machines manually operated or automated?

EPS block cutting machines can be either manually operated or automated, depending on the level of precision and efficiency required for the production process. Automated machines often feature programmable controls and computerized systems for enhanced accuracy and productivity.

What safety precautions should be taken when operating EPS block cutting machines?

Operators should receive proper training on machine operation and safety protocols. Safety measures may include wearing protective gear such as gloves and goggles, ensuring proper ventilation in the workspace, and implementing emergency stop mechanisms.

Can EPS block cutting machines be customized to cut specific shapes or designs?

Yes, many EPS block cutting machines offer customization options to cut foam blocks into specific shapes or designs according to the requirements of the end product. This can be achieved through programmable controls or specialized cutting attachments.

How do EPS block cutting machines contribute to the efficiency of EPS foam production?

By precisely cutting large foam blocks into smaller pieces or shapes, EPS block cutting machines optimize material usage and reduce waste, thereby improving overall production efficiency and cost-effectiveness.

What maintenance is required for EPS block cutting machines?

Regular maintenance tasks may include cleaning and lubricating moving parts, inspecting blades or wires for wear, and calibrating cutting parameters to ensure consistent performance. Additionally, periodic checks for alignment and electrical safety are recommended.