Importing EPS Beads Making Machine from China

We are the leading EPS machine manufacturer, and we have this EPS beads making machine to produce the EPS beads continuously with high efficiency, and please fee free to contact us now to get detailed info now.

Our EPS Beads Making Machine

Discover the cutting-edge technology of our EPS Beads Making Machine, engineered for precision and efficiency in producing high-quality EPS beads. Upgrade your packaging process today for superior results. Contact us now to learn more and revolutionize your production line!

- You can count on precise temperature control, ensuring optimal melting and molding of EPS beads.

- With its user-friendly interface, you’ll effortlessly adjust settings for varying bead sizes and densities.

- Experience enhanced productivity thanks to the machine’s high-speed operation, allowing for quicker production cycles.

- Say goodbye to downtime with its robust construction and reliable performance, minimizing maintenance needs.

- Enjoy versatility in output options, whether you require standard beads or customized shapes, the machine delivers with precision.

Special Features about EPS Beads Making Machine

Precision Control

Our EPS Beads Making Machine features advanced technology for precise control over bead size, density, and shape. This ensures consistent quality and customization options tailored to your specific packaging needs.

Efficient Production

Experience enhanced productivity with our machine's high-speed operation and streamlined workflow. Its optimized design minimizes production downtime and maximizes output, boosting overall efficiency in your manufacturing processes.

Versatility and Flexibility

Adaptability is key with our EPS Beads Making Machine. Whether you require standard EPS beads or specialized shapes for unique packaging solutions, our machine offers versatility and flexibility to meet a diverse range of production demands.

EPS Beads Making Machine Applications

Packaging Industry

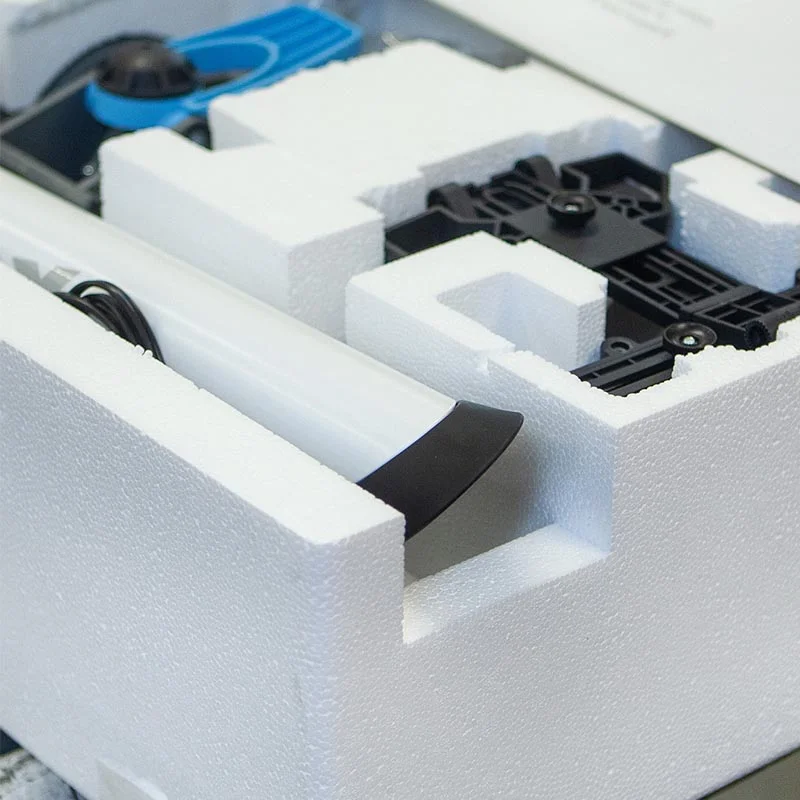

EPS beads are used to create protective packaging materials such as foam inserts, corner protectors, and packaging blocks, providing cushioning and shock absorption during shipping and handling.

Construction Industry

EPS beads are utilized in the construction sector for producing lightweight concrete, insulation panels, and decorative architectural elements, contributing to energy efficiency and enhancing structural integrity.

Agriculture Industry

EPS beads are utilized for manufacturing seedling trays, plant pots, and protective packaging for agricultural products, providing a lightweight and insulating environment for seed germination and plant growth while ensuring safe transportation of agricultural goods.

Why Choose Our EPS Beads Making Machine

-

High Efficiency:Our EPS beads making machine is designed for maximum efficiency, with streamlined processes and optimized workflows. It ensures rapid production of expanded beads, minimizing production time and increasing output capacity, thereby enhancing overall manufacturing efficiency.

-

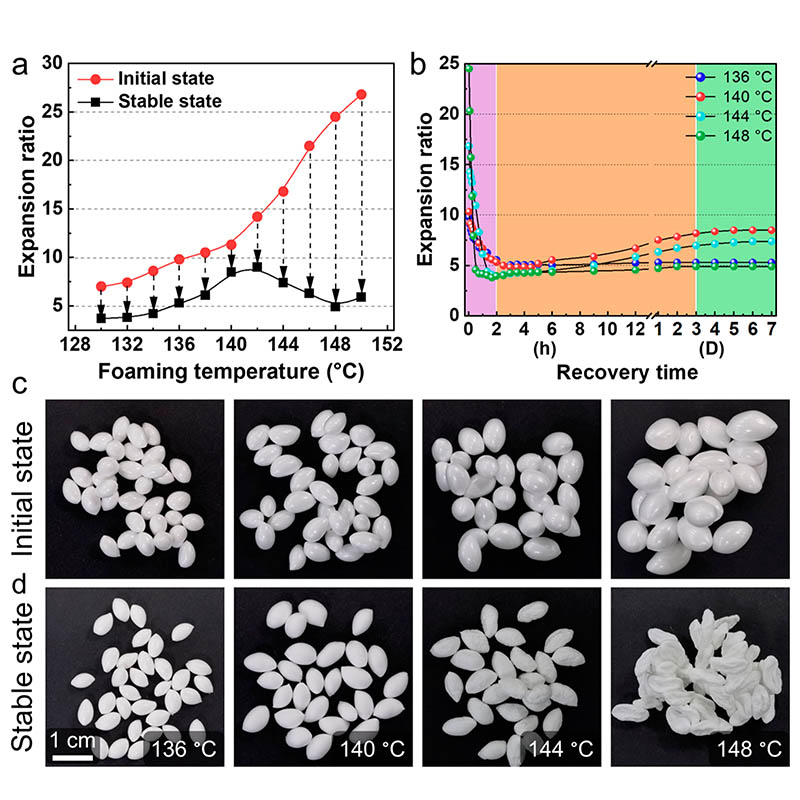

Precision Control:Our machine offers precise control over key parameters such as temperature, pressure, and bead expansion ratio. This precision control ensures consistent and uniform expansion of EPS beads, resulting in high-quality end products with minimal variation.

-

Energy Efficiency:Our EPS beads making machine is engineered for energy efficiency, incorporating advanced heating and cooling systems that minimize energy consumption without compromising production quality. This feature helps reduce operational costs and environmental impact, making it a sustainable choice for manufacturers.

-

Versatility:Our machine is highly versatile, capable of producing expanded beads of various sizes, densities, and specifications to meet diverse customer requirements. Whether for packaging, insulation, or construction applications, our EPS beads making machine can adapt to different production needs, providing flexibility and versatility to manufacturers.

-

Reliability and Durability:Built with robust materials and precision engineering, our EPS beads making machine is known for its reliability and durability. It is engineered to withstand continuous operation in demanding manufacturing environments, minimizing downtime and maintenance costs for manufacturers. With a reputation for long-term performance and reliability, our machine offers peace of mind to customers, ensuring uninterrupted production and consistent product quality.

FAQs about EPS Bead Making Machine

What are EPS beads?

EPS beads are small spherical particles made from Expanded Polystyrene (EPS) foam, commonly used as lightweight packaging material and insulation.

How does an EPS beads making machine work?

The machine melts polystyrene pellets, expands them with steam, and then shapes them into uniform beads. These beads can be customized in size, density, and shape to suit specific packaging needs.

What types of products can be made with EPS beads?

EPS beads can be used to create a wide range of products, including packaging inserts, insulation panels, lightweight concrete, and decorative items.

Is the machine customizable for different production needs?

Yes, many EPS beads making machines offer customization options for bead size, density, and shape. Additionally, some machines can be integrated into existing production lines for seamless operation.

What are the benefits of using EPS beads?

EPS beads offer several advantages, including lightweight construction, excellent cushioning properties, moisture resistance, and thermal insulation. They are also recyclable and environmentally friendly.

Can EPS beads be recycled?

Yes, EPS beads are recyclable and can be processed into new EPS products or other materials. Recycling programs and facilities are available in many regions to collect and recycle EPS waste.

Are there safety precautions to consider when operating an EPS beads making machine?

Yes, operators should follow safety protocols and guidelines provided by the manufacturer to prevent accidents and ensure safe operation of the machine. This may include wearing appropriate protective gear, observing machine operation procedures, and conducting regular safety inspections.

What factors affect the quality of EPS beads produced by the machine?

Several factors influence the quality of EPS beads, including temperature control, steam pressure, dwell time within the expansion chamber, and the size and density of the raw EPS beads. Proper adjustment and monitoring of these parameters ensure consistent and high-quality bead expansion.

Can the EPS beads making machine accommodate different sizes and densities of EPS beads?

Yes, EPS beads making machines are designed to accommodate various sizes and densities of EPS beads. They can be adjusted to produce beads with specific characteristics tailored to meet the requirements of different applications and industries.

What are the key components of an EPS beads making machine?

The main components of an EPS beads making machine typically include an expansion chamber, a steam heating system, a cooling and conditioning system, a material handling system, and automation and control systems.