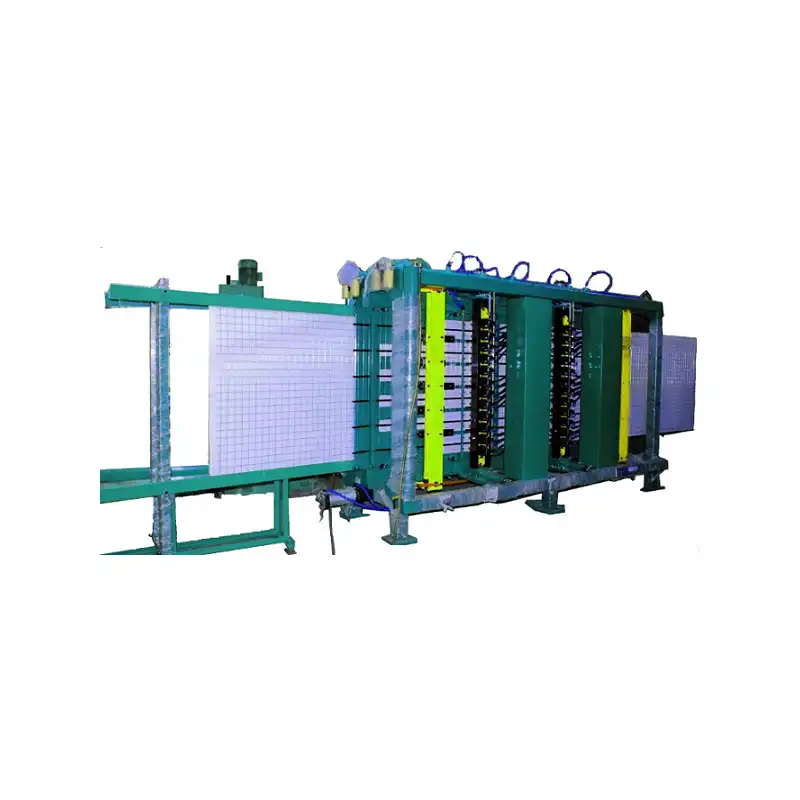

EPS 3D Panel Machine

We offer EPS 3D panel machines designed for efficient production of decorative and structural 3D EPS panels. Our machines provide precise molding, high-speed output, and consistent quality, allowing manufacturers to create lightweight, durable, and visually appealing panels for interior walls, facades, and architectural applications with reliable performance.

Why Choose Our EPS 3D Panel Machine

High Production Efficiency – 3D panel machines produce panels quickly with minimal manual labor, increasing output while reducing production time and operational costs for manufacturers.

Precision and Consistency – These machines ensure uniform dimensions, accurate shapes, and consistent surface quality, delivering reliable panels suitable for decorative and structural applications.

Versatile Design Options – EPS 3D panel machines can create various patterns, textures, and thicknesses, allowing manufacturers to offer customizable panels for interior and exterior use.

Durable and Lightweight Panels – Panels produced are strong yet lightweight, simplifying transportation, installation, and handling while maintaining structural integrity and long-term performance.

Reduced Material Waste – Efficient molding and cutting processes minimize EPS material waste, lowering costs and supporting environmentally friendly manufacturing practices.

3D EPS Wire Mesh Panel Machine

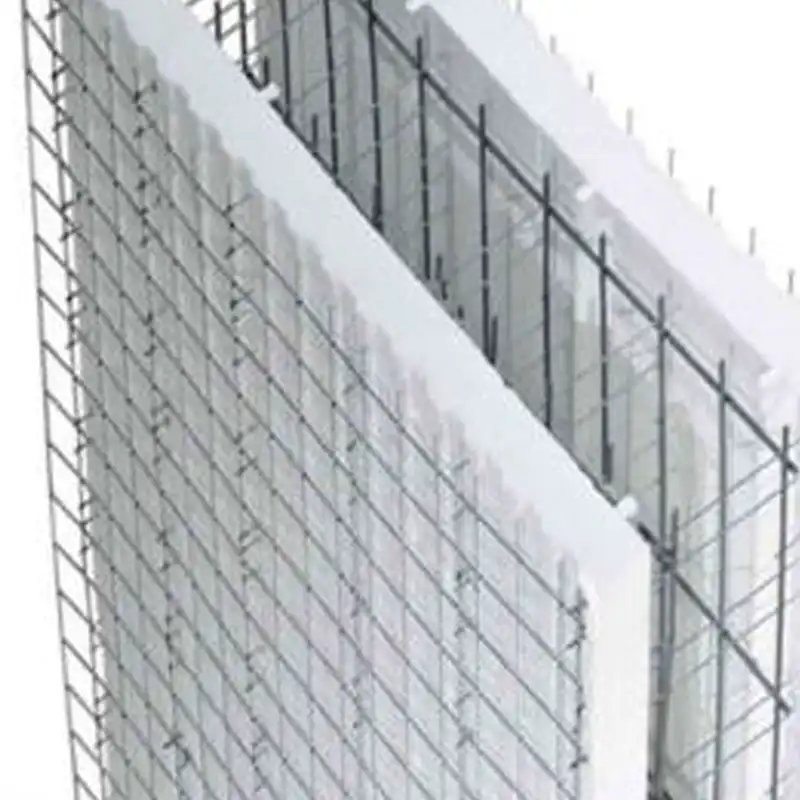

Reinforced Structural Strength – 3D EPS wire mesh panel machines integrate steel or wire mesh into panels, providing enhanced load-bearing capacity, durability, and long-lasting structural performance.

Lightweight Construction – Panels remain lightweight despite reinforcement, making transportation, handling, and installation easier while reducing overall structural load and supporting faster construction timelines.

Improved Thermal Insulation – EPS core combined with wire mesh maintains excellent insulation properties, reducing energy consumption and maintaining consistent indoor temperatures for industrial and residential buildings.

Customizable Panel Designs – Machines allow flexible shaping, sizes, and mesh placement, enabling manufacturers to produce panels that meet architectural, aesthetic, and structural requirements.

Efficient Production Process – Automated molding and integration of wire mesh reduce labor needs, minimize material waste, and maintain consistent quality, increasing overall manufacturing efficiency.

ePS 3D panel machine Applications

Constructing Exterior Walls

EPS 3D panels are a popular choice for building exterior walls due to their lightweight nature, ease of assembly, and good insulation properties. They can be used in various residential and commercial construction projects.

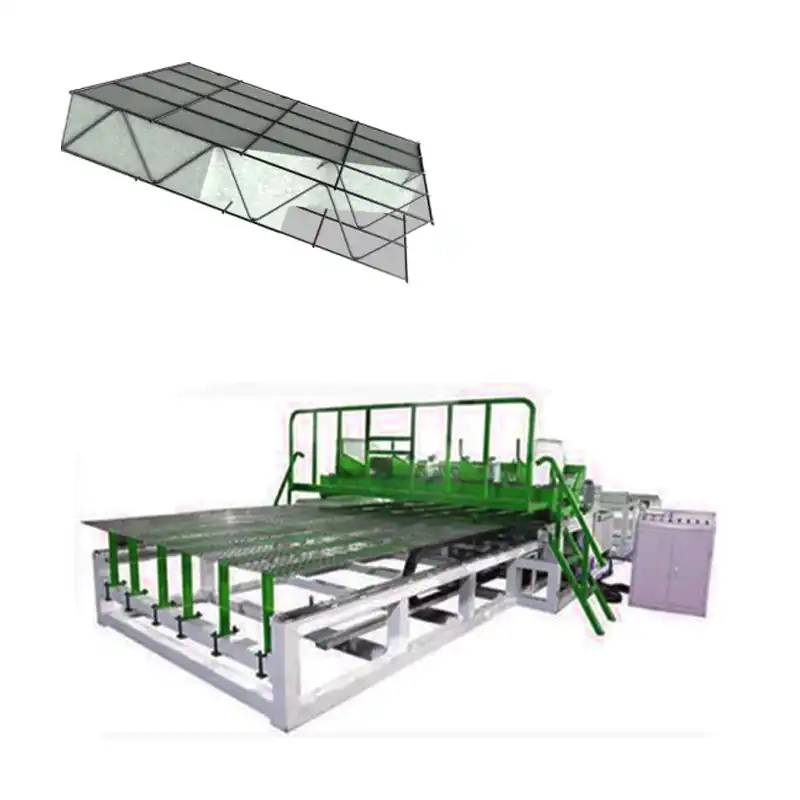

Building Roofs and Floors

EPS 3D panels can also be used for roofs and floors, depending on the specific panel design and thickness. Their insulating properties contribute to energy efficiency in both applications.

Creating Interior Partitions

Non-load bearing interior walls and partitions can be efficiently constructed using EPS 3D panels. They offer a faster alternative to traditional framing methods while providing good sound insulation within a building.

3D EPS panels

3D EPS panels

We offer 3D EPS panels designed for decorative and structural applications. Our panels combine lightweight EPS cores with durable surfaces, providing excellent insulation, easy installation, and customizable designs. Ideal for interior walls, facades, and architectural projects, they deliver aesthetic appeal, long-lasting performance, and energy efficiency for residential and commercial buildings.

3D EPS core panels

We offer 3D EPS core panels designed for strong, lightweight, and insulated construction solutions. Our panels combine a durable EPS core with optional wire mesh reinforcement, providing excellent thermal performance, structural strength, and versatility for walls, facades, and prefabricated buildings, supporting efficient installation and long-lasting building performance.

FAQs about EPS 3D Panel Machine

What are EPS 3D Panels?

An EPS 3D Panel Machine is a piece of automated equipment used to manufacture lightweight building panels made from:

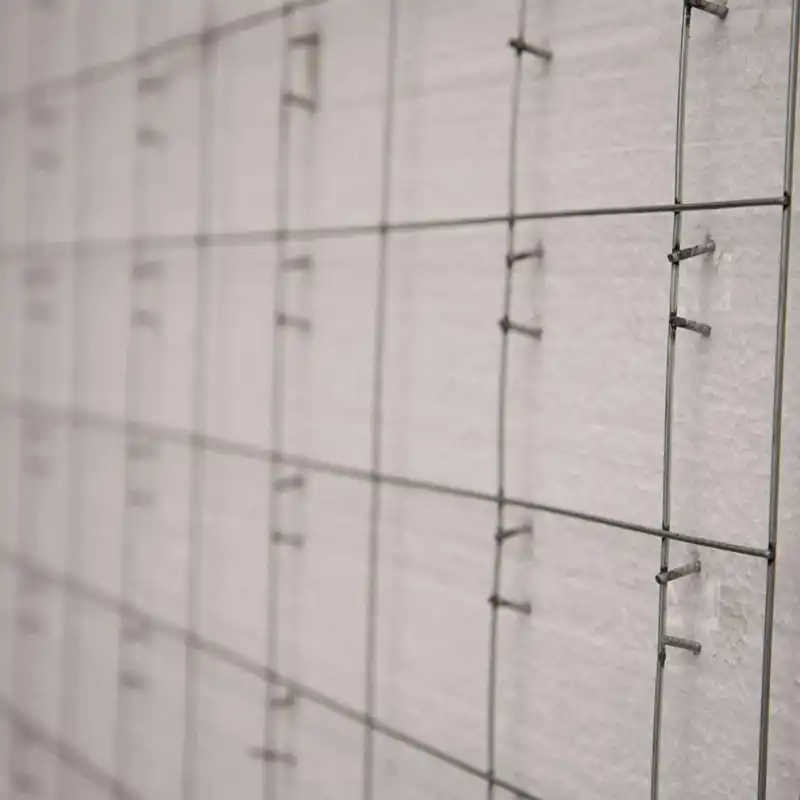

- EPS Core: Expanded Polystyrene beads, a white, lightweight plastic material known for its good insulation properties.

- Wire Mesh Facings: Welded wire mesh on both the front and back sides of the panel, providing structural reinforcement.

These EPS 3D panels are becoming increasingly popular in construction due to several advantages:

- Faster Construction: The prefabricated panels can be quickly assembled on-site, reducing overall building time.

- Lightweight & Strong: The combination of EPS and wire mesh creates a lightweight panel with good structural strength.

- Energy Efficient: The EPS core provides excellent thermal insulation, helping to reduce heating and cooling costs.

- Durable: EPS 3D panels are resistant to moisture, mold, and pests. They can also withstand strong winds and earthquakes.

If you’re in the construction business, an EPS 3D Panel Machine could be a valuable tool for producing high-quality, energy-efficient building components.

what is EPS 3D panel machine

EPS 3D Panels are lightweight building materials made with a core of EPS (expanded polystyrene) sandwiched between welded wire mesh on both sides. They offer advantages like good insulation, fire resistance, and ease of construction.

What are the benefits of using an EPS 3D Panel Machine?

Faster production compared to manual methods.

Consistent panel quality and reduced waste.

Lower production costs per panel.

Increased construction speed on projects.