Custom EPP Solar Wafer Packaging from China

Specializing in custom EPP solar wafer packaging from China, we offer precision-molded solutions that ensure the safe transport of photovoltaic cells. Our packaging features anti-static properties and excellent shock absorption to prevent micro-cracks and damage. Leverage our competitive manufacturing and design expertise for a durable, reusable, and sustainable solution tailored to your specific wafer size.

Get EPP Solar Wafer Packaging Wholesale

Exceptional Shock Absorption: The foam’s cellular structure effectively dissipates impact energy, preventing damage to fragile wafers from drops and bumps.

Lightweight and Cost-Effective: EPS is extremely light, reducing shipping costs, and its economical production makes it a budget-friendly packaging solution.

Excellent Thermal Insulation: It maintains a stable temperature within the package, protecting wafers from thermal shock during transit in varying climates.

Customizable for Secure Fit: EPS can be easily molded into precise shapes, creating custom cavities that perfectly cradle wafers and prevent movement.

Moisture and Chemical Resistant: The closed-cell structure of EPS resists water absorption and is inert to most chemicals, ensuring a clean and dry environment.

Customize Your Desired EPP Solar Wafer Packaging

Wafer Size and Configuration

We design and mold the packaging to perfectly fit your specific wafer size and quantity. Whether you need a single-wafer tray or a multi-wafer stack, our custom-fit cavities prevent movement and abrasion, drastically reducing the risk of micro-cracks and breakage during transit.

Anti-Static and Electrical Properties

Solar wafers are highly sensitive to static discharge. We can incorporate specific additives into the EPP material to achieve a desired level of anti-static protection, preventing electrostatic damage (ESD) and ensuring the integrity of your wafers throughout the entire supply chain, from production to installation.

Structural Design for Durability

We engineer the EPP packaging with customized ribbing, wall thickness, and corner reinforcement to absorb maximum shock and impact. This tailored structural design ensures your solar wafers are protected from external forces, even in harsh shipping conditions, providing peace of mind and reducing product loss.

Integration with Shipping Containers

We design our EPP packaging to seamlessly integrate with your existing shipping containers, optimizing space utilization and further enhancing protection. This includes creating modular trays that stack securely, as well as designing outer boxes or sleeves that hold the EPP inserts firmly in place, streamlining your logistics process.

solar wafer packaging EPP mold

We specialize in designing and manufacturing high-precision EPP molds for solar wafer packaging. Our EPP molds are crafted to produce lightweight, shock-absorbent trays with specific anti-static properties. We ensure a custom fit that prevents movement and protects delicate wafers from impact, vibration, and electrostatic discharge, reducing micro-cracks and breakage during transport.

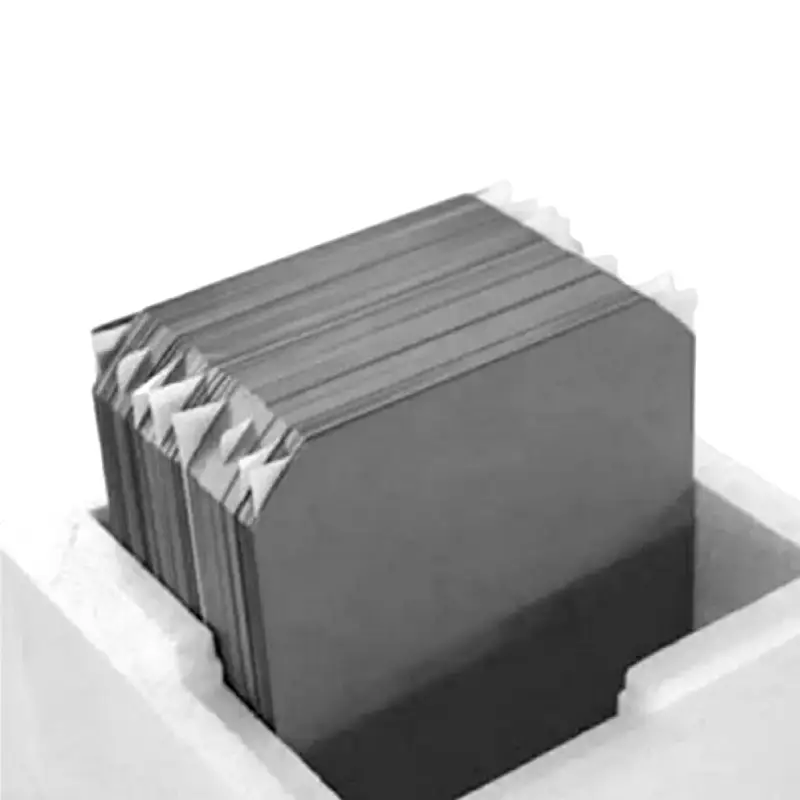

EPP foam solar wafer packaging

We specialize in crafting EPP foam packaging for solar wafers. Our solutions are custom-molded to provide superior shock absorption and thermal insulation, protecting delicate wafers from micro-cracks and temperature fluctuations during transit. Featuring anti-static properties and reusability, our packaging is an efficient, safe, and sustainable choice for the photovoltaic supply chain.

EPP Solar Wafer Packaging FAQs

what is solar wafer?

A solar wafer, also known as a silicon wafer, is a thin, fundamental slice of crystalline silicon that serves as the building block for manufacturing solar cells.

It’s the core semiconductor substrate where the magic of converting sunlight into electricity happens. The process involves slicing a large ingot of highly pure silicon into these wafers, which are then treated and doped with specific chemicals to create the necessary electrical properties for a functional solar cell.

There are two main types: monocrystalline wafers, which are more efficient, and polycrystalline wafers, which are a more cost-effective option. These wafers are crucial to the solar energy industry, as they are the very foundation of solar panels and determine the efficiency and longevity of the final product.

what is solar wafer EPP packaging?

EPP (Expanded Polypropylene) solar wafer packaging is a highly specialized type of protective foam packaging designed to safeguard extremely fragile and valuable silicon wafers during transportation and handling. The EPP material is lightweight and durable, but its most critical properties are its exceptional shock absorption and resilience.

The closed-cell structure of the foam allows it to absorb multiple impacts without losing its shape or protective qualities, which is vital for preventing micro-cracks that can compromise the wafers’ performance. This packaging is custom-molded to create snug, individual cavities for each wafer, preventing them from shifting or touching each other.

Additionally, it can be manufactured with anti-static properties to protect the sensitive electronic components from electrostatic discharge (ESD) and is often reusable, making it a sustainable choice in the photovoltaic supply chain.

what is solar wafer EPP packaging used for?

EPP solar wafer packaging is a specialized solution used to provide comprehensive protection for solar wafers throughout their journey from manufacturing to installation.

It addresses the unique vulnerabilities of these extremely fragile components, ensuring their integrity and performance are not compromised. The key uses for this packaging include:

Shipping and Logistics: It secures wafers during transport, cushioning against shocks and vibrations to prevent micro-cracks that can reduce efficiency.

Storage and Handling: The packaging provides a safe, organized way to store wafers, protecting them from physical damage and contamination in warehouses and on factory floors.

ESD Protection: It utilizes anti-static properties to guard against electrostatic discharge, a major risk to sensitive electronic components like solar wafers.

Inventory Management: The stackable and customizable trays help streamline inventory, making it easier to count, move, and track wafers with minimal handling.