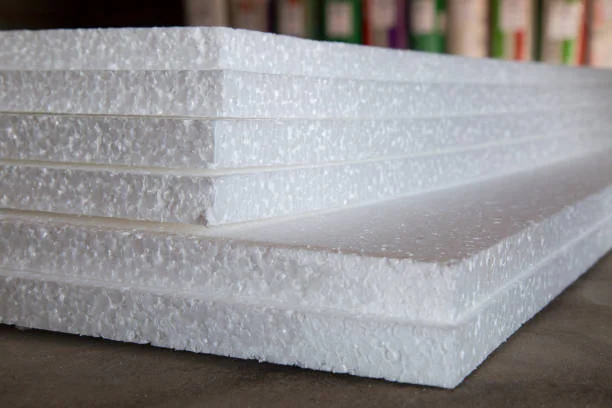

Working with thick styrofoam can be a frustrating experience, often resulting in jagged edges, crumbling material, and a big mess. But what if there was a better way? In this guide, we’ll explore the best way to cut thick styrofoam, sharing professional tips and tricks that will help you achieve clean, precise cuts every time, without the hassle.

Whether you’re a professional needing to shape insulation, mastering the art of cutting thick styrofoam is a valuable skill. We’ll cover the essential tools, techniques, and safety precautions that will transform your projects from sloppy to spectacular. Get ready to cut like a pro!

Thick Styrofoam Cutting Tools

Choosing the right tool is the most important step for successfully cutting thick styrofoam. While a simple utility knife can work for very thin sheets, it will quickly become frustrating and messy with thicker blocks. To achieve clean, professional-looking cuts, you need a tool specifically designed for the job. Here are some of the best tools for cutting thick styrofoam:

- Band Saw: For large, straight cuts in thick styrofoam blocks, a band saw with a specialized fine-toothed blade is an excellent choice. It provides a stable and powerful way to handle large pieces, but it will create a lot of mess.

- Hot Wire Cutter: This is the go-to tool for a clean, smooth cut. A heated wire melts through the foam, leaving a precise, sealed edge without any dust or debris. They are available in various styles, including handheld cutters and table-mounted scroll saws for more intricate designs.

- Electric Foam Cutter/Hot Knife: Similar to a hot wire cutter, a hot knife has a thicker, heated blade that slices through denser foams with ease. They are perfect for both straight and contoured cuts and are a favorite for sculpting and crafting.

- Serrated Knife or Electric Carving Knife: For a low-cost option, a long, serrated knife can be effective. An electric carving knife is a step up, as its oscillating blades make quick work of thick foam, though the cuts may not be as smooth as with a hot tool.

Thick Styrofoam Cutting Tips

Cutting thick styrofoam doesn’t have to be a frustrating, messy affair. With the right techniques, you can achieve clean, professional results every time. These expert tips will help you avoid the common pitfalls of crumbling edges and uneven cuts. By focusing on preparation, choosing the right tool, and mastering your cutting technique, you’ll be well on your way to perfecting your foam projects.

Preparation and Safety First

Before you even make the first cut, proper preparation is key to a successful project. Always work in a well-ventilated area to avoid inhaling any fumes, especially when using hot tools. Lay down a drop cloth or newspaper to catch any debris, and be sure to wear safety goggles to protect your eyes. Securing the styrofoam block on a stable surface with clamps will prevent it from shifting, ensuring a straighter, safer cut.

The Right Tool for the Job

Selecting the appropriate tool is crucial for achieving a clean finish. For intricate shapes and dust-free cuts, a hot wire cutter is your best friend, as it melts through the foam, leaving a smooth edge. For a more budget-friendly approach, a serrated utility knife or an electric carving knife can work, but be prepared for some minor crumbling. Remember to use a fresh blade for the cleanest results and less effort.

Cutting Technique Matters

Your technique is just as important as your tools. When using a hot wire cutter, let the heat do the work and guide the wire slowly and steadily through the foam without forcing it. For manual knives, apply even pressure and use a sawing motion rather than a single, forceful push.

For long, straight cuts, a straight edge or a guide rail will ensure a perfectly straight line, while practicing on scrap pieces will help you get a feel for the tool before you start on your final project.

Best Way to Cut Thick Styrofoam

Choosing the right cutting method is crucial for achieving clean and precise results with styrofoam. The best approach depends heavily on the material’s thickness and density. Here, we’ll explore various methods tailored to different types of foam, ensuring you get the best possible outcome for your project, whether it’s a small craft or a large-scale construction job.

Thin and low-density Styrofoam

For thin and low-density styrofoam, a simple utility knife is often the most effective tool. To begin, lay the styrofoam flat on a stable workbench and secure it with a heavy object to prevent any movement during the cut. This ensures a more accurate and controlled process.

To make a clean cut, use a ruler as a guide. Press the ruler firmly against the styrofoam and, with less pressure, move the utility knife along its edge at a constant speed. The goal is to complete the cut in one pass to avoid creating jagged lines or tearing the material.

Styrofoam of medium thickness and density

For styrofoam of medium thickness and density, the hot wire cutting method is an excellent choice. Start by setting up your hot wire cutting equipment, ensuring the power connection is secure and the wire is properly heated.

Once ready, fix the styrofoam block in place and slowly guide it toward the hot wire. This allows the wire to gradually melt through the material, creating a smooth, sealed edge. Pay close attention to controlling your speed and maintaining a consistent cutting angle to achieve a perfectly straight line.

Another effective technique for this type of foam is using a serrated knife. Choose a sharp serrated knife with fine teeth on the blade for the best results. Hold the handle with both hands to apply moderate and even pressure. Rather than trying to cut through the material in one go, make multiple passes, gradually working your way through the foam. This method reduces tearing and gives you better control over the final cut.

Thick and high-density Styrofoam

When dealing with thick and high-density styrofoam, an electric foam cutter is a powerful tool. Before you begin, adjust the cutter’s depth and angle settings to match your project’s specifications. After securely fixing the styrofoam, turn on the power and move the cutter at a steady, constant speed. The heated blade will slice through the dense material with ease, leaving a clean and precise cut.

For larger pieces, an electric saw with a fine-toothed blade designed for foam is a great option. During the cutting process, it is essential to keep the saw stable to prevent any wobbling. Make your cuts in multiple passes, going a certain depth each time.

This technique avoids the risk of the material breaking or the cut surface becoming uneven, which can happen if you try to cut through it all at once. Regardless of the method you choose, always prioritize safety by wearing protective gear and working in a well-ventilated area.

How to Cut Styrofoam?

Cutting Styrofoam precisely and cleanly can be challenging, but using the right tools and techniques makes a significant difference. Here’s a guide covering effective methods for cutting this lightweight material safely and accurately.

Tools Needed

The following tools are recommended for various Styrofoam cutting methods, ensuring a smooth and successful project outcome. Selecting the appropriate tool depends on the desired precision and the thickness of the foam.

- Hot Wire Cutter: This is often the best choice for clean, smooth, and intricate cuts, as the heat melts the foam instead of tearing it, reducing mess and jagged edges.

- Utility Knife or Craft Knife: Essential for straight lines and general shaping when a hot wire isn’t available, but it requires a very sharp blade to minimize foam crumbling.

- Fine-toothed Saw: Useful for very thick Styrofoam blocks where other tools might be inadequate, but it will generally create a more textured, less smooth edge.

- Straight Edge or Ruler: Necessary for guiding the cutting tool when aiming for perfectly straight lines or making measurements for accurate sizing.

- Marker or Pencil: Used for marking the cutting lines clearly on the Styrofoam surface before starting the actual cutting process.

Step 1: Prepare the Cutting Surface and Safety Gear

Ensure you have a clean, flat, and stable work area that can tolerate minor heat or potential mess from foam debris. Covering the surface with scrap material or a drop cloth simplifies cleanup afterward.

Cutting Styrofoam, especially with a hot wire, can release fumes, so good ventilation is crucial for safety. Always wear gloves and safety glasses to protect your hands and eyes from the tools and any loose foam particles.

Step 2: Mark Your Desired Cut Lines

Use a permanent marker or pencil to accurately draw the intended cutting path onto the Styrofoam surface. Double-check your measurements and the line placement to avoid errors before cutting.

Employ a straight edge or ruler to ensure that any straight lines are precise and consistent. For curved or complex shapes, sketching the outline clearly helps guide the tool during the subsequent cutting process.

Step 3: Choose and Set Up Your Cutting Tool

If using a hot wire cutter, allow it sufficient time to heat up completely, as a fully heated wire yields the smoothest cut. Ensure the power cord is safely positioned and out of the cutting path.

For a utility or craft knife, ensure the blade is brand new or very sharp to slice through the foam with minimal dragging or tearing. A dull blade will shred the material, leaving ragged edges.

Step 4: Execute the Initial Cut Slowly

When using a hot wire cutter, gently push the foam into the heated wire, letting the heat melt the material. Maintain a slow, steady pace for the cleanest, most professional-looking edge.

If using a knife or saw, apply steady, controlled pressure and make multiple shallow passes rather than trying to cut through the entire thickness in one go. This technique helps prevent cracking or tearing the foam.

Step 5: Clean Up and Refine Edges

Once the main cuts are complete, remove any loose foam dust or debris from your workspace and the cut pieces. You can use a vacuum or a soft brush for effective cleanup.

If the edges are slightly rough, they can often be smoothed gently with fine-grit sandpaper or a very sharp blade held at a low angle. Handle the Styrofoam carefully during this refinement stage to avoid damage.

Styrofoam Cutting Safety Precautions

Here are some safety precautions when cutting thick Styrofoam:

- Protective equipment: Wear goggles to prevent debris from entering the eyes, and wear gloves to protect the hands from cuts and abrasions.

- Good ventilation: Make sure the work area is well ventilated to reduce the accumulation of dust and possible harmful gases generated by cutting.

- Tool inspection: Before using the cutting tool, carefully check whether it is intact, whether the wire is broken, and whether the blade is sharp and firmly installed.

- Stable placement: Place the thick Styrofoam firmly on a stable workbench to prevent it from moving during cutting and causing accidents.

- Avoid overloading: Follow the rated power and instructions of the cutting tool to avoid tool failure or danger caused by overloading.

- Fire prevention measures: Styrofoam is flammable, so keep away from open flames and high temperature sources such as candles, stoves, etc. when cutting.

- Keep away from children: Make sure there are no children in the cutting work area to avoid accidental injuries.

- Power safety: If you use an electric cutting tool, keep your hands dry when plugging and unplugging the power plug to prevent electric shock.

- Cutting direction: Follow the design and safe operation guidelines of the tool to determine the correct cutting direction and avoid danger caused by reverse operation.

- End of work: After cutting, turn off the power in time, store the tool properly, and clean up the debris in the work area.

Always keep safety in mind, follow these precautions to minimize the risk of accidents when cutting thick Styrofoam.

Styrofoam Cutting Environmental Considerations

The environmental impact of cutting styrofoam is a significant concern, largely because the material itself poses substantial environmental challenges. Styrofoam, or expanded polystyrene (EPS), is a petroleum-based plastic that is not biodegradable and can take hundreds of years to decompose. This makes proper disposal crucial to prevent it from accumulating in landfills and polluting ecosystems. Here are some key considerations:

- Pollution: Due to its lightweight nature, styrofoam is easily carried by wind and water, breaking down into microplastics that can harm wildlife and contaminate food chains. Even small scraps from cutting can contribute to this problem if not contained properly.

- Waste Management: Cutting styrofoam, especially with tools like a band saw, generates a lot of small foam beads and dust. This waste must be collected and disposed of responsibly, as it can easily become litter that pollutes land and waterways.

- Recycling Challenges: While styrofoam is technically recyclable, it is not accepted in most curbside recycling programs due to its low density and high transportation costs. It requires specialized facilities to be processed, and many areas lack these resources, leading most styrofoam to end up in landfills.

- Chemical Release: When cutting styrofoam with hot tools, the heated plastic can release styrene gas, a potential human carcinogen. This is why it is essential to work in a well-ventilated area to minimize inhalation and health risks.

Conclusion

Mastering the best way to cut thick styrofoam is a game-changer for any project, big or small. By using the right tools, like hot wire cutters, and employing careful techniques, you can achieve professional-quality results with clean edges and minimal mess. We’ve shown that with a little practice and the proper approach, those daunting, thick blocks of foam can be easily shaped to your will, saving you time and frustration.

Remember that safety should always be your top priority. Ensure you’re working in a well-ventilated area, wearing protective gear, and handling tools with care. A clean workspace and a steady hand are your best friends in this process. By following these pro tips, you’re now equipped to tackle any styrofoam cutting task with confidence and precision, turning your creative visions into reality.

For all your large-scale projects, don’t settle for less. Get wholesale styrofoam blocks from our trusted partner, Epsole. Their high-quality, durable foam is perfect for everything from insulation to artistic sculptures, providing the ideal foundation for your next masterpiece. Visit their site today to find the perfect materials and start creating with the best.

-300x300.webp)