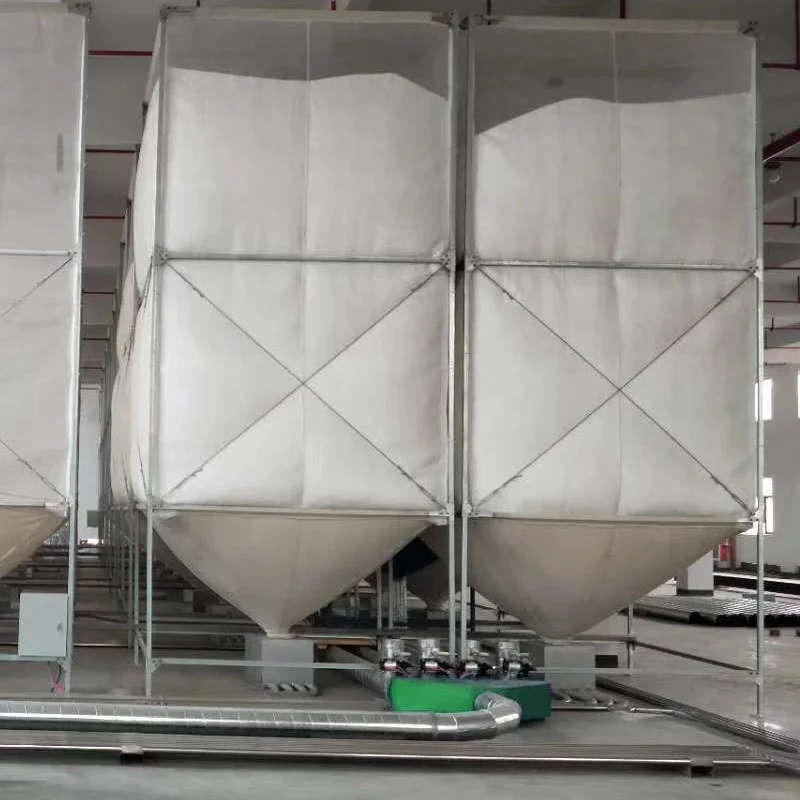

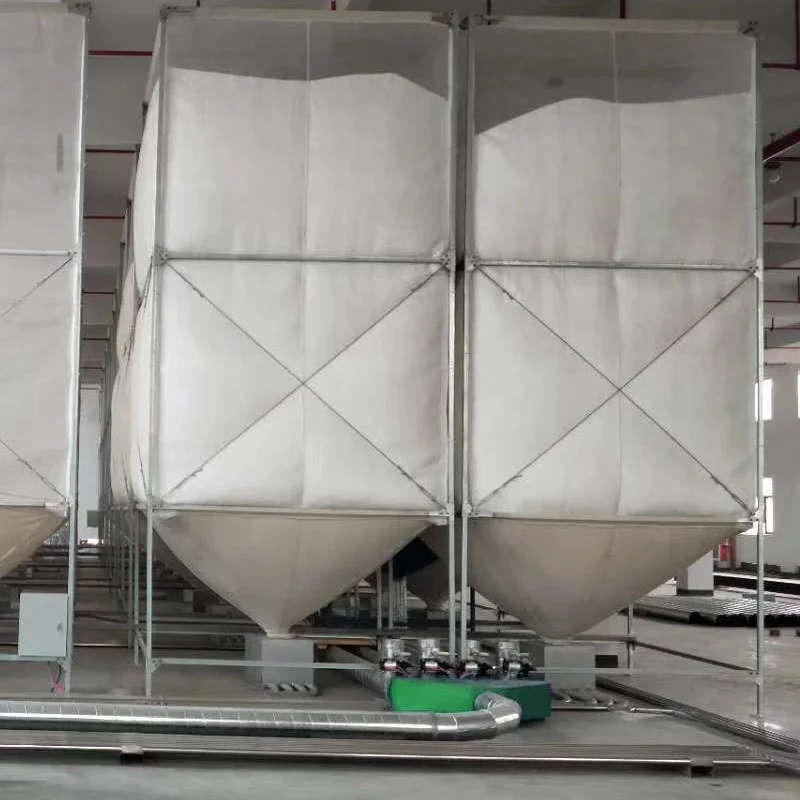

We supply the Auto Silo EPS Beads Storage system, a fully automated solution for handling and storing EPS raw materials. We provide efficient storage that minimizes waste and ensures the integrity of your beads. This system enhances material flow, optimizes space, and supports continuous production with its smart design.

We manufacture the Auto Silo EPS Beads Storage system featuring advanced technology for automated inventory and material management. This solution is engineered for seamless integration into your existing facility layout, providing real-time data on material levels and consumption. We offer a smart, scalable system designed to adapt to your evolving production demands effortlessly.

Intelligent inventory tracking: We supply silos equipped with accurate level sensors and software that provide precise, continuous monitoring of bead quantities. This data allows for streamlined procurement planning, minimizing sudden shortages and ensuring your production schedule remains uninterrupted and highly organized.

Modular and scalable design: Our system is built on a modular framework, allowing you to easily add or reconfigure silos as your business grows or product requirements change. We offer flexible expansion options that protect your initial investment while allowing you to increase your total storage capacity over time effortlessly.

Enhanced factory safety: The enclosed, automated nature of our silo system significantly reduces the need for manual handling of large bags of raw material. We provide a safer working environment by minimizing dust exposure and potential lifting injuries, prioritizing the well-being and efficiency of your team.

Complete data logging: The system automatically records material inflow, outflow, and storage conditions. We offer detailed reports essential for quality control traceability and consumption analysis. This feature provides valuable business intelligence for optimizing processes and reducing material waste effectively.

Auto Silo EPS Beads Storage is an automated system for storing expanded polystyrene (EPS) beads, ensuring efficient organization and retrieval in a controlled environment.

Automated: Auto Silo EPS Beads Storage utilizes automated systems for loading, unloading, and organizing EPS beads, reducing manual labor and increasing efficiency. Touch Screen and PLC

Level sensors (up location sensor, down location sensor).

Controlled Environment: It provides a controlled environment, maintaining optimal conditions for storing EPS beads to prevent degradation and maintain quality.

Space Optimization: The system optimizes space utilization by stacking EPS beads vertically, maximizing storage capacity within limited floor space.DN150/DN200 diameter galvanized pipe as a whole EPS transportation system.

Inventory Management: Fireproof EPS silo storage bags.It enables precise inventory tracking and management, allowing for real-time monitoring of bead levels and efficient retrieval when needed.

Customizable Configurations: Auto Silo EPS Beads Storage offers customizable configurations to accommodate different storage capacities and operational requirements, providing flexibility for various applications.

The auto silo EPS beads storage system is equipped with automated loading and unloading mechanisms, streamlining the process and minimizing manual labor.

Integrated sensors continuously monitor the silo's capacity, providing real-time data on bead levels and ensuring optimal storage conditions.

Specialized dust control measures prevent contamination of EPS beads during storage, maintaining their purity and quality for use in manufacturing processes.

The mechanical recycling machine typically uses mechanical processes such as crushing, shredding, and compacting to break down EPS foam waste into smaller pieces. It may include equipment such as crushers, granulators, and densifiers to facilitate the recycling process.

Chemical recycling machines employ chemical processes to break down EPS foam waste into its constituent molecules, which can then be used to produce new materials or products. They may utilize solvents, catalysts, or other chemical agents to depolymerize EPS foam and extract useful components.

The Auto Silo EPS Beads Storage system is engineered to deliver exceptional performance across a wide array of industrial applications where large-scale, reliable EPS processing is essential. We provide solutions that seamlessly integrate into diverse manufacturing environments, ensuring optimal material flow and efficiency for every user. We support EPS block molding facilities. We offer continuous, on-demand supply of aged EPS beads directly to block molding machines. This constant feed minimizes production downtime, ensuring a steady output of uniform, top-tier EPS blocks used extensively in the construction and insulation sectors globally. We cater to shape molding production. Our system precisely manages the storage and transfer of various bead sizes required for intricate shape molding. We ensure the integrity of the beads for producing complex packaging, automotive parts, and decorative items with consistent density and excellent surface finish. We integrate with EPS recycling plants. The Auto Silo effectively manages the storage of recovered or re-processed EPS material before it is re-introduced into the production cycle. We provide a clean and efficient holding solution that streamlines the recycling process, supporting sustainable and cost-effective operations. We are ideal for pre-expansion processes. We provide a controlled storage environment essential for the optimal aging of pre-expanded EPS beads. This precise control ensures the beads reach the correct density and stability before further processing, resulting in reliable final product performance and quality.

cutting-edge automation

ensuring precise inventory control

We manufacture the Auto Silo EPS Beads Storage system to give your production line a definitive advantage in efficiency and material management. Choosing our silos means investing in a reliable, automated system that guarantees the optimal quality of your EPS beads from storage to expansion. We offer a premium solution built for continuous, high-volume operations.

We ensure optimal material integrity. We provide a sealed, climate-controlled environment that shields EPS beads from ambient moisture, dust, and temperature fluctuations. This crucial protection maintains the beads’ foaming capability, leading to consistent, top-grade finished products every time.

We offer superior space utilization. Our vertical silo design minimizes the floor area required for storing large volumes of raw EPS beads. We supply custom heights and configurations, allowing you to maximize storage density in your existing facility, resulting in a more organized and efficient production space.

We provide fully automated material handling. The system incorporates advanced sensors and automated transfer mechanisms, eliminating manual labor and reducing the risk of human error or contamination. We manufacture the system for smooth, uninterrupted material flow directly into your pre-expanders or processing equipment.

We guarantee long-term durability. We manufacture our silos using robust, industrial-grade materials designed to withstand the rigors of continuous factory operation. This resilient construction ensures a long service life with minimal maintenance requirements, securing your investment for years to come.

We are leading EPS manufacturer to provide all-in-one EPS solutions for your EPS project. Welcome to contact us at any time if you are looking for EPS machine, EPS material and many other EPS related product, please feel free to contact us now to get instant help.

Copyright © 2024 Hangzhou Epsole technologies Co.Ltd.

WhatsApp us