Importing Air Cooling EPS Block Molding Machine from China

Looking for an air cooling EPS block molding machine for your project? Look no further than Epsole, a trusted EPS machine manufacturer based in China. Our air cooling EPS block molding machine is designed to recycle EPS foam. With our expertise and commitment to quality, we can tailor the machine to meet your specific requirements. Contact us now to request a quote and know more about how air cooling EPS moulding machine can benefit your project

Our Air Cooling EPS Block Molding Machine

Take your EPS foam recycling efforts to the next level with our Air Cooling EPS Block Molding Machine. Partner with us, a leading EPS machine manufacturer from China, to revolutionize your recycling process.

Contact us today to request a quote and discover how our innovative air cooling EPS moulding machine can enhance your operations and contribute to a sustainable future.

Invest in our Air Cooling EPS Block Molding Machine today to benefit from its robust structure, anti-corrosion features, and efficient heat conduction. Maximize your production efficiency and ensure long-term durability. Contact us for a quote and revolutionize your EPS manufacturing process!

Strong Machine Structure: Welded with high-quality profile steel plate and strong rectangular tubes, ensuring a robust machine structure from the base.

High Strength and Non-Deformation: After undergoing heating treatment to release welding stress, the machine frames possess high strength, resistance to deformation, and can withstand the expansive force from high-density products.

Excellent Anti-Corrosion Performance: To prevent rust, the machine undergoes shot blast treatment or sand treatment. It is then painted with multiple layers of anti-rust bottom paint and surface paint, ensuring superior anti-corrosion performance and extending the machine’s lifetime.

Efficient Heat Conduction: The mold’s surface is crafted from special aluminum alloy panel or stainless steel sheet, enabling efficient heat conduction, favorable tensile strength, and prolonged service life.

EPS Block Moulding Machine Working Process

EPS beads are pre-expanded using steam to achieve the desired density and size. This process involves heating the EPS beads in a pre-expander machine, causing them to expand and become lighter.

Once pre-expanded, the EPS beads undergo a treatment process to ensure uniformity and consistency in their properties. This may involve cooling, drying, or other treatments to prepare them for the molding process.

The treated EPS beads are then stored in silos, ready for use in the block molding machine. The silos provide a convenient and organized storage solution, allowing for easy access to the EPS beads during the molding process.

The main step of the process involves the EPS block molding machine. Here, the treated EPS beads are fed into the machine's mold cavity, where they are subjected to heat and pressure to form solid EPS blocks. The machine's automated processes ensure precise molding and consistent block quality.

After the blocks are molded, they may undergo further processing, such as cutting into panels or shaping into specific forms. This step allows for customization of the EPS blocks to meet the desired specifications for the final product.

Finally, the finished EPS panels or shapes are ready for use in various applications, such as packaging, insulation, or construction. The completed products offer lightweight, durable, and versatile solutions for a wide range of industries.

Air Cooling EPS Block Molding Machine Applications

Construction Industry

Insulation Panels: EPS blocks produced by these machines are commonly used as insulation panels in buildings. They provide thermal insulation, which helps in maintaining indoor temperature and reducing energy consumption. Lightweight Concrete: EPS blocks can also be used as lightweight aggregates in concrete mixes, resulting in lightweight concrete with improved thermal and acoustic insulation properties.

Model Making

EPS blocks serve as a popular medium for sculptors and artists due to their lightweight nature and ease of carving. Artists can create intricate sculptures and artworks using EPS blocks as the base material.

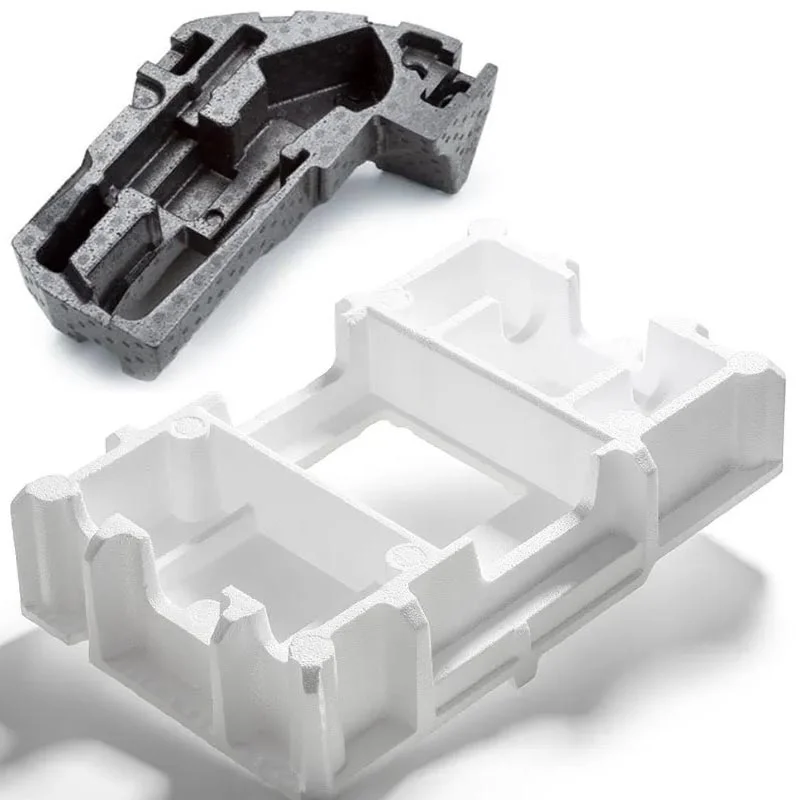

EPS Electronic Appliance Packaging

EPS (Expanded Polystyrene) foam is commonly used in electronic appliance packaging due to its lightweight, protective, and insulating properties. Packaging for electronic appliances is crucial to ensure that they reach consumers in optimal condition, free from damage during transit or handling. Here's how EPS foam is utilized in electronic appliance packaging

Why Choose Our EPS Block Molding Machine

-

-

Quality of Output: Highlight the superior quality of EPS blocks produced by your machine. This includes uniform density, smooth surfaces, and precise dimensions, ensuring consistency and reliability in the final products.

-

Efficiency and Productivity: Emphasize the efficiency and productivity of your EPS block molding machine. This could include features such as fast cycle times, high production capacity, and minimal downtime, allowing for increased output and profitability.

-

Energy Efficiency: If your machine is designed with energy-efficient features or utilizes innovative technologies to reduce energy consumption, this can be a significant selling point. Energy-efficient machines not only save operational costs but also contribute to sustainability efforts.

-

Ease of Operation: Highlight user-friendly features and intuitive controls that make operating the machine easy and straightforward. This includes features such as automated processes, touch-screen interfaces, and remote monitoring capabilities.

-

Customization Options: If your EPS block molding machine offers customization options, such as the ability to produce blocks of varying sizes, densities, or shapes, emphasize this flexibility. Customization capabilities cater to diverse customer needs and expand the machine’s versatility.

-

FAQs

What is an air cooling EPS block molding machine?

An air cooling EPS block molding machine is a type of equipment used in the production of expanded polystyrene (EPS) foam blocks. It utilizes a system of fans and airflow to cool down the molded EPS blocks after they have been formed.

How does an air cooling EPS block molding machine work?

The machine heats EPS beads and injects them into molds, where they expand to form large blocks of foam. After molding, the blocks are subjected to air cooling, where fans circulate air around them to cool and solidify the foam.

What are the advantages of using air cooling systems in EPS block molding?

Air cooling systems are energy-efficient and relatively simple to set up compared to water cooling systems. They are also more environmentally friendly since they do not require large amounts of water.

Can air cooling EPS block molding machines handle large-scale production?

While air cooling systems are often used in smaller-scale operations, they can also be adapted for moderate to large-scale production depending on the specific requirements and setup of the manufacturing facility.

Are air cooling EPS block molding machines suitable for regions with limited water resources?

Yes, air cooling systems are particularly well-suited for areas where water availability or quality is a concern since they do not rely on water for the cooling process.

What types of products can be manufactured using EPS blocks produced by air cooling machines?

EPS blocks produced by air cooling EPS block molding machines are versatile and can be used in various industries, including construction, packaging, insulation, and arts and crafts.

Is the cooling process uniform across all parts of the EPS block?

Air cooling systems are designed to provide uniform cooling across the entire surface of the EPS blocks, ensuring consistent quality and structural integrity.

What maintenance is required for air cooling EPS block molding machines?

Regular maintenance of fans, air ducts, and other components is necessary to ensure optimal performance and efficiency. Cleaning and inspection should be carried out according to the manufacturer’s guidelines.

Can air cooling EPS block molding machines be automated?

Yes, many modern air cooling EPS block molding machines feature automation capabilities, including programmable controls and monitoring systems for improved efficiency and quality control.

Are there any safety considerations when operating air cooling EPS block molding machines?

Operators should be trained in safe handling practices, including proper use of protective equipment and adherence to operating procedures to minimize the risk of accidents or injuries during machine operation