The world of making has undergone a remarkable transformation. Gone are the days when intricate designs and precise cuts were solely the domain of skilled artisans or large-scale industrial facilities. Today, hobbyists and professionals alike can achieve remarkable results with the help of CNC cutting machines.

But what exactly are these machines, and how do they unlock a universe of creative possibilities? Let’s delve into the fascinating world of CNC cutting technology.

What is a CNC Cutting Machine?

At its core, a CNC (Computer Numerical Control) cutting machine is a computer-controlled marvel that utilizes a cutting tool or a laser to precisely cut a wide range of materials.

These machines translate digital designs into physical reality, enabling users to create intricate shapes and components with exceptional accuracy. Think of it as a robotic arm wielding either a high-powered laser or a specialized cutting tool, meticulously following instructions to bring your vision to life.

Delving Deeper into the World of CNC Cutting: Exploring Specific Machines

CNC cutting machines come in various forms, each offering distinct advantages for specific materials and applications. Let’s take a closer look at three prominent CNC cutting technologies: CNC laser cutters, CNC plasma cutters, and CNC wire EDM machines.

What is CNC Laser Cutting Machine?

A CNC laser cutting machine is a computer-controlled marvel that utilizes a highly focused laser beam to precisely cut a wide range of materials. Imagine a super-powered cutting tool made of light – that’s essentially what a CNC laser cutter does.

What is CNC Plasma Cutting Machine?

A CNC plasma cutting machine is a powerhouse built for tackling thick and conductive metals. Unlike a laser cutter that uses light, a CNC plasma cutter utilizes a high-temperature plasma torch to cut through materials like steel and aluminum. Imagine a miniature lightning bolt controlled by a computer – that’s the essence of a CNC plasma cutter.

What Is CNC Wire Cutting Machine?

A CNC wire EDM (Electrical Discharge Machining) machine is a specialized tool in the CNC cutting family. Unlike its laser and plasma counterparts, it doesn’t utilize light or extreme heat for cutting. Instead, it employs a unique and precise method known as electrical discharge machining. Imagine a tiny,

The Power of CNC Technology

The magic of CNC cutting lies in its ability to seamlessly blend automation with precision. Here’s what makes these machines such a game-changer:

- Unmatched Precision: Unlike traditional cutting methods that rely on human skill, CNC machines are guided by pre-programmed instructions. This ensures meticulous accuracy, allowing for the creation of even the most intricate designs with flawless cuts.

- Repeatability Made Easy: Need to produce identical parts in bulk? CNC machines excel at replicating designs with perfect consistency. This makes them ideal for tasks like manufacturing components or creating multiple versions of the same craft project.

- Material Versatility: CNC cutting machines are not limited to a single material. They can handle a wide range of materials, including wood, plastic, acrylic, foam, and even some soft metals. This opens doors to a vast array of creative applications.

- Efficiency Champion: Repetitive cutting tasks can be a time-consuming and laborious process. With CNC machines, these tasks become automated, freeing you to focus on other aspects of your project or significantly increasing your production output.

Different CNC Cutting Machine Types

The world of CNC cutting isn’t a one-size-fits-all solution. Different cutting methods cater to specific needs and materials. Here’s a closer look at some of the major CNC cutting machine types:

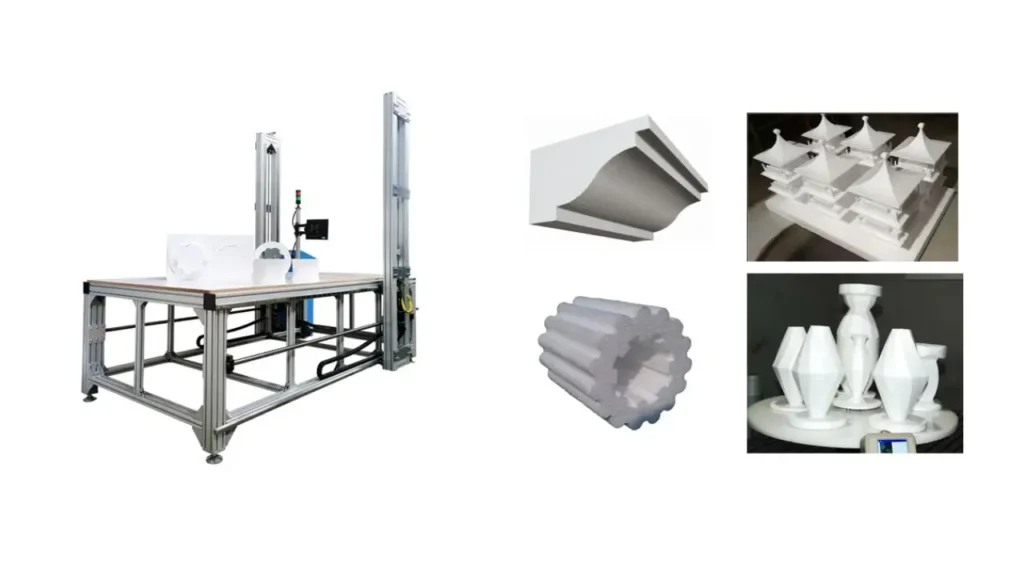

- CNC Router: A workhorse of the cutting world, the CNC router utilizes a fast-spinning cutting tool to remove material. This versatility makes it perfect for cutting a variety of materials like wood, plastic, and foam. Think of it as a miniature (and much more precise) handheld router on steroids.

- CNC Laser Cutter: Employing a high-powered laser beam to cut through material with pinpoint accuracy, the CNC laser cutter excels at handling intricate designs and thin materials. Imagine a focused beam of light acting like a scalpel, leaving clean, precise cuts in its wake.

Other CNC Cutting Techniques

While CNC routers and laser cutters are the most common types, there are other fascinating cutting technologies within the CNC family:

- CNC Plasma Cutter: This powerhouse utilizes a high-temperature plasma torch to cut through conductive materials like steel and aluminum. It’s ideal for thicker materials and industrial applications where clean edges are less critical.

- CNC Wire EDM (Electrical Discharge Machining): This specialized technique uses a thin, electrically charged wire to erode material, allowing for highly precise cuts of intricate shapes in conductive materials like tool steel.

What Materials Can a CNC Machine Cut?

The ability to cut various materials is a major advantage of CNC machines. However, the specific materials a CNC machine can handle depend on the cutting technology it uses. Here’s a breakdown of the most common CNC cutting machines and their material compatibility:

CNC Router:

- Strengths: Wood, plastic, acrylic, foam, composite materials (like MDF and plywood)

- Limitations: May not be suitable for very hard materials like metals or thick materials depending on the cutting tool.

CNC Laser Cutter:

- Strengths: Wood, plastic, acrylic, fabric, leather, thin sheet metal

- Limitations: Generally limited to thinner materials due to the nature of laser cutting. May not be ideal for highly reflective materials like polished metals.

CNC Plasma Cutter:

- Strengths: Conductive metals like steel and aluminum (thicker materials)

- Limitations: Not suitable for non-conductive materials like wood or plastic. Cut edges may not be as clean as with other methods.

CNC Wire EDM (Electrical Discharge Machining):

- Strengths: Conductive materials like tool steel, stainless steel (for intricate shapes)

- Limitations: Limited to conductive materials. Slower cutting speed compared to other methods.

Here’s a table summarizing the material compatibility of different CNC machines:

| Machine Type | Strengths | Limitations |

|---|---|---|

| CNC Router | Wood, plastic, acrylic, foam, composite materials | Hard materials, thick materials |

| CNC Laser Cutter | Wood, plastic, acrylic, fabric, leather, thin sheet metal | Thicker materials, highly reflective materials |

| CNC Plasma Cutter | Conductive metals (steel, aluminum) | Non-conductive materials, clean edge quality |

| CNC Wire EDM | Conductive materials (tool steel, stainless steel) | Non-conductive materials, cutting speed |

Remember:

It’s always best to consult the machine’s manual or manufacturer for specific information on what materials it can cut effectively.

This is a general guideline, and the specific capabilities of a CNC machine may vary depending on its model and power source (spindle power for routers, laser wattage for laser cutters).

Some CNC machines may be equipped with specialized tools or features that expand their material compatibility.

Choosing the Right CNC Cutting Machine

With so many options available, selecting the right CNC machine can feel overwhelming. Here are some key factors to consider:

Cost: CNC cutting machines range in price to suit various budgets. Hobbyist-friendly models are available, while industrial machines

Machine Size: The size of the machine dictates the maximum size of the material you can work with.

Material Compatibility: Ensure the machine is suitable for the materials you plan to use most often.

Power Source: Spindle power (for routers) and laser wattage (for laser cutters) determine the thickness of the material you can handle. Consider the cutting speed and desired edge quality as well.

Ease of Use: Select a machine that aligns with your experience level, offering an easy setup and operation process. Some machines may require more technical knowledge than others.

Cost Considerations and Beyond: Exploring the Potential of CNC Cutting Machines (Continued)

- Cost: CNC cutting machines range in price to suit various budgets. Hobbyist-friendly models can be found for under $1,000, while industrial machines can cost tens of thousands of dollars or more. Consider the features, capabilities, and brand reputation when making your choice.

Beyond the Machine: Essential Considerations for Successful CNC Cutting

Owning a CNC cutting machine is just the first step. Here are some additional factors to keep in mind:

- Software: CNC machines rely on design and control software to translate your digital creations into instructions for the machine. Familiarize yourself with popular software options and choose one that aligns with your skillset and project needs.

- Safety: CNC machines are powerful tools, and safety should be a top priority. Always wear appropriate safety gear, such as eye protection, dust masks, and hearing protection when operating the machine. Make sure to follow proper safety protocols and be aware of the machine’s capabilities and limitations.

- Workholding: Securing your material to the cutting bed is crucial for precise cuts and safety. Different workholding techniques are used for various materials and project types. Research and understand proper workholding methods for the materials you plan to use.

- Learning Resources: The world of CNC cutting is vast and ever-evolving. Thankfully, there’s a wealth of online resources available, including tutorials, forums, and communities. Utilize these resources to expand your knowledge, troubleshoot challenges, and discover new techniques.

CNC Cutting Machine Applications

CNC cutting machines are a transformative technology used in a wide range of industries and applications. Here are just a few examples:

- Prototyping: The ability to create precise and repeatable cuts makes CNC machines ideal for rapidly prototyping new designs. This allows designers and engineers to quickly test and iterate on their ideas, accelerating the development process.

- Signage: From intricate logos to eye-catching storefront signs, CNC machines can create a wide variety of signage with professional-looking results. They offer unmatched precision for lettering and complex designs.

- Manufacturing: CNC cutting machines are a mainstay in modern manufacturing. They can precisely cut a vast array of materials, enabling the creation of consistent, high-quality parts for various products.

- Arts and Crafts: The ability to transform digital designs into physical creations has opened doors for hobbyists and crafters. CNC machines can be used to create unique jewelry, personalized gifts, home décor accents, and much more.

Conclusion

In conclusion, CNC cutting machines have revolutionized the way we create. These computer-controlled marvels offer unmatched precision, repeatability, and the ability to handle a wide range of materials. From prototyping and signage to crafting unique works of art and manufacturing high-quality parts, CNC cutting machines empower users to transform their visions into reality.

Whether you’re a seasoned professional or a passionate hobbyist eager to unleash your creativity, there’s a CNC cutting machine out there to perfectly suit your needs. With careful consideration of factors like machine size, material compatibility, power source, ease of use, and budget, you can find the ideal machine to elevate your projects to the next level.

Ready to Get Started? Get a Quote for Your Dream CNC Cutting Machine Today!

Here at [Your Company Name], we understand the excitement and potential that CNC cutting machines offer. We carry a wide range of CNC machines from industry-leading brands, ensuring you’ll find the perfect fit for your application and budget. Our knowledgeable team is here to answer your questions and guide you through the selection process.

Don’t wait any longer to bring your ideas to life! Contact us today for a free, no-obligation quote on your desired CNC cutting machine. We’re here to help you unlock a world of creative possibilities with the power of CNC technology.