Many people consider Styrofoam, or expanded polystyrene (EPS), to be an inert and waterproof material, making them believe it’s immune to mold growth. However, the reality might be surprising. This common packaging and insulation material, while not a food source for mold itself, can still become a breeding ground under specific conditions, raising significant concerns for homeowners and businesses alike.

This article will delve into the science behind mold growth on Styrofoam, exploring the factors that contribute to its development. We’ll uncover how moisture, organic debris, and environmental conditions can transform an otherwise benign surface into a problematic habitat for black mold, dispelling common misconceptions along the way.

What is Black Mold ?

“Black mold” on Styrofoam refers to the growth of various mold species that appear dark in color, most commonly Stachybotrys chartarum, which is often associated with potential health concerns due to its ability to produce mycotoxins. While Styrofoam (Expanded Polystyrene or EPS) itself is not an organic food source for mold, the mold can still colonize its surface.

This happens when moisture is consistently present on the Styrofoam (e.g., from condensation, leaks, or high humidity) and there’s a buildup of organic particulate matter like dust, dirt, or other debris on the surface. These organic deposits then provide the necessary nutrients for the mold spores to germinate and grow, creating unsightly black patches and potentially releasing spores into the air.

What Materials Does Black Mold Grow On?

Black mold, specifically Stachybotrys chartarum, requires a food source rich in cellulose to grow. While it needs constant moisture to thrive, it can develop on a wide range of organic materials commonly found in homes and buildings. Understanding these surfaces is key to prevention and effective remediation.

- Insulation: Some types of insulation can become saturated and provide a suitable environment for growth.

- Drywall and Gypsum Board: The paper backing on these materials provides a perfect cellulose food source.

- Wood and Wood Products: Wood framing, particleboard, and subflooring are all susceptible to mold growth.

- Paper and Cardboard: Books, boxes, and other paper products absorb moisture and can quickly become a food source.

- Carpeting and Fabric: The fibers in carpets, upholstery, and clothing can hold moisture and sustain mold.

Styrofoam Characteristics

Styrofoam, officially known as Expanded Polystyrene (EPS), is a versatile and widely used material characterized by its lightweight nature and excellent insulation properties. It’s produced by expanding small polystyrene beads into a foam, which results in a closed-cell structure predominantly composed of air (around 98%). This unique composition grants it a range of beneficial characteristics, making it suitable for diverse applications from packaging to construction and crafting.

- Versatility: Styrofoam can be easily molded, cut, and shaped into virtually any form, making it highly adaptable for custom packaging, insulation boards, decorative items, and more.

- Lightweight: Comprising mostly air, Styrofoam is incredibly light, which significantly reduces shipping costs for packaged goods and makes it easy to handle in construction and other applications.

- Thermal Insulation: Its closed-cell structure traps air, creating an effective barrier against heat transfer. This makes it an excellent insulator, helping to maintain temperatures in packaging and contributing to energy efficiency in buildings.

- Shock Absorbency/Cushioning: The foam’s ability to compress and absorb energy upon impact provides superior cushioning, protecting fragile items during transit and handling.

- Moisture Resistance: The closed-cell nature means Styrofoam does not readily absorb water, allowing it to maintain its insulating properties and structural integrity even in damp environments.

- Durability and Dimensional Stability: It is resistant to decay, mold, and rot, and maintains its shape and size over time, contributing to a long service life in various applications.

Can Black Mold Grow on Styrofoam?

Studies have shown that on polyethylene materials with similar chemical properties to polystyrene foam, black mold has a certain possibility of growth when the ambient humidity is high and there are organic pollutants. Experiments have found that the tiny pores and roughness on the polyethylene surface provide sites for the attachment of mold spores to a certain extent.

In addition, for polystyrene materials, although there is limited research on black mold, some studies have pointed out that the surface properties of such polymers may change when they are in a humid, warm and unclean environment for a long time, thereby increasing the risk of mold growth.

Although these studies are not directly aimed at polystyrene foam, they provide us with valuable references and clues for speculating on the growth of black mold on Styrofoam. It should be noted that different polymer materials still have differences in physical and chemical properties, so the research results of similar materials cannot be simply applied to polystyrene foam.

But these research results at least remind us to pay attention to the hygiene of polystyrene foam in specific environments to prevent possible mold growth and its potential harm.

How to Prevent Styrofoam Black Molds?

Preventing black mold on Styrofoam is crucial for maintaining a healthy environment. While Styrofoam itself isn’t a food source, mold thrives on moisture and organic debris. Implementing proactive measures ensures this common material remains free from unsightly and potentially harmful fungal growth.

Control Humidity

Maintaining low indoor humidity levels is paramount for preventing mold growth on Styrofoam. Aim for relative humidity between 30% and 50% using dehumidifiers, especially in damp basements or bathrooms. This deprives mold spores of the essential moisture needed for germination and proliferation on surfaces.

Monitor humidity with a hygrometer and consider using exhaust fans during activities like showering or cooking. Proper climate control minimizes condensation on cold Styrofoam surfaces, which often provides the ideal damp conditions for mold to establish itself and begin to spread.

Ensure Proper Ventilation

Adequate airflow is vital to prevent stagnant, moisture-rich air around Styrofoam. Open windows and doors whenever possible to allow fresh air circulation. Good ventilation helps to dry out damp areas quickly, reducing the likelihood of moisture accumulating on surfaces where mold could thrive.

Utilize fans to improve air circulation in enclosed spaces containing Styrofoam, such as insulated walls or storage containers. Ensuring consistent air movement discourages the buildup of humidity and helps disperse airborne mold spores, making it harder for them to settle and grow.

Keep Surfaces Clean

Regularly clean Styrofoam surfaces to remove dust, dirt, and any other organic debris that can serve as a food source for mold. A simple wipe-down with a damp cloth can be effective. This minimizes the nutrients available for mold spores, even if some moisture is present.

For Styrofoam used in insulation or packaging, ensure surrounding areas are also kept free of accumulated grime. Periodic cleaning prevents the buildup of microscopic organic particles that mold can feed on, making the environment less hospitable for fungal colonization and growth.

Promptly Address Leaks and Water Damage

Any water leaks or instances of water damage involving Styrofoam must be addressed immediately and thoroughly. Repair the source of the leak, then dry the affected Styrofoam and surrounding areas completely within 24-48 hours to prevent mold from taking hold and spreading quickly.

Inspect areas where Styrofoam is used for insulation, particularly in basements, attics, or exterior walls, for signs of water intrusion. Ignoring even small leaks can create persistent damp conditions, turning Styrofoam into a prime breeding ground for black mold, requiring extensive remediation.

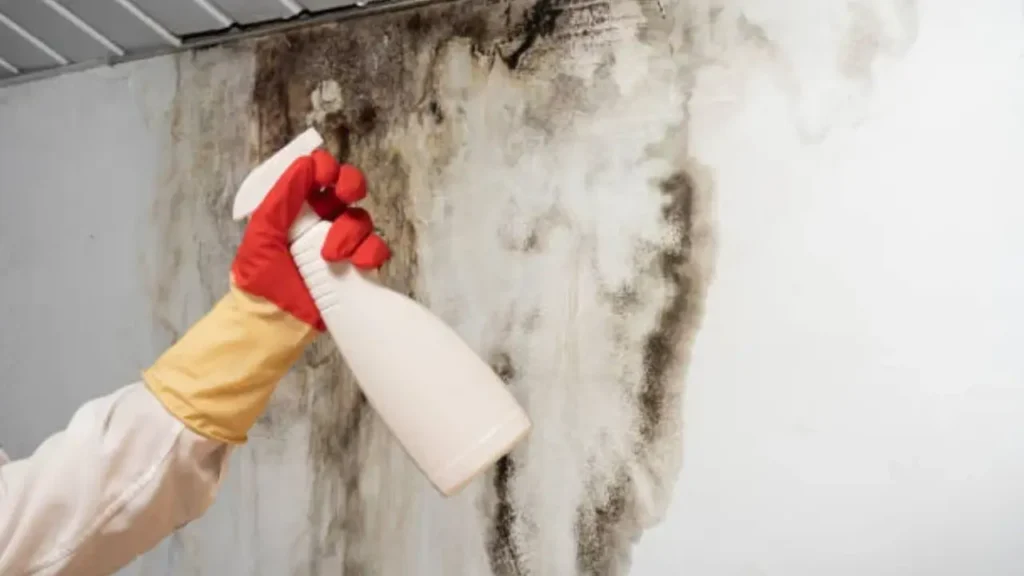

How to Remove Black Mold From Foam?

Removing black mold from foam requires careful attention to safety and thoroughness to prevent recurrence. While some foam types may be beyond saving, for minor mold growth, a methodical approach can effectively clean the affected areas and restore the material’s integrity safely.

Prioritize Safety

Before attempting any mold removal, always don appropriate personal protective equipment (PPE). This includes wearing gloves, safety goggles, and an N95 respirator mask to avoid inhaling spores. Good ventilation is also crucial to minimize exposure during the cleaning process.

Protect yourself from direct contact with mold and cleaning agents, which can irritate skin and respiratory systems. Ensure pets and children are away from the affected area. Your health and safety are paramount when dealing with potentially harmful mold contaminants.

Prepare the Cleaning Solution

For most foam types, a mild solution of dish soap and water, or a specialized mold cleaner designed for porous materials, is effective. Avoid harsh chemicals like bleach on foam, as it can degrade the material and isn’t effective against mold roots in porous surfaces.

Alternatively, a mixture of white vinegar and water (1:1 ratio) can be used for its antifungal properties. Test any cleaning solution on an inconspicuous area first to ensure it doesn’t discolor or damage the foam. Prepare enough solution for thorough cleaning.

Clean the Molded Area

Gently dab or wipe the affected foam surface with a cloth dampened with your chosen cleaning solution. Avoid scrubbing aggressively, as this can embed spores deeper into the foam or release them into the air. Work from the outside of the mold patch inward.

For persistent mold, you may need to apply the solution and let it sit for 5-10 minutes before wiping. Ensure you are removing the mold, not just smearing it. Dispose of cleaning cloths carefully in a sealed bag immediately after use.

Rinse and Dry Thoroughly

After cleaning, gently rinse the foam surface with a clean, damp cloth to remove any cleaning solution residue. It is crucial not to saturate the foam with water, as excess moisture will only encourage mold to return. Dab gently to remove moisture.

The most critical step is ensuring the foam is completely dry before returning it to use or placing it back in its location. Use fans or dehumidifiers to accelerate drying; natural air drying in a well-ventilated area is also effective. Moisture left behind guarantees mold regrowth.

Are Black Mold Spores Harmful?

Black mold spores, particularly from species like Stachybotrys chartarum, can indeed be harmful, especially for sensitive individuals. While the term “toxic black mold” is often sensationalized, these molds can produce mycotoxins, which are secondary metabolites that can become airborne along with the spores and potentially cause health issues when inhaled or touched. The severity of symptoms depends on various factors, including the individual’s sensitivity, the duration of exposure, and the concentration of spores in the air.

Mycotoxin Concerns: While direct links to severe illnesses from airborne mycotoxins in residential settings are still being researched, prolonged or heavy exposure to some mold species (including Stachybotrys chartarum) has been associated with more severe symptoms like fatigue, headaches, and concentration problems in some individuals.

Allergic Reactions: The most common effect of black mold spores is triggering allergic reactions. Symptoms can include sneezing, coughing, nasal congestion, runny nose, itchy eyes, skin rashes, and sore throat, similar to hay fever.

Respiratory Issues: For individuals with asthma or other respiratory conditions, exposure to mold spores can worsen their symptoms, leading to wheezing, shortness of breath, and asthma attacks.

Irritation: Even for those without allergies, mold spores and volatile organic compounds (mVOCs) produced by mold can cause irritation to the eyes, skin, nose, throat, and lungs.

Fungal Infections: People with compromised immune systems (e.g., those with HIV/AIDS, organ transplant recipients, or chemotherapy patients) are at a higher risk of developing more serious fungal infections in the lungs or other parts of the body if exposed to mold spores.

Does Styrofoam Insulation Get Moldy?

Yes, Styrofoam insulation can get moldy, though it’s not the Styrofoam itself that typically provides the food source for mold.

Here’s why and how it happens:

Not a Food Source, But a Surface: Styrofoam (Expanded Polystyrene, or EPS) is a synthetic, inorganic material. Mold needs organic material to feed on. Therefore, the EPS foam itself doesn’t provide nutrients for mold growth.

The Role of Moisture: The primary driver for mold growth on any surface, including Styrofoam insulation, is moisture. If Styrofoam insulation becomes consistently damp or wet due to:

- Condensation: Warm, moist air coming into contact with a cooler Styrofoam surface can lead to condensation. If this moisture isn’t properly managed or allowed to dry, it creates the ideal environment.

- Leaks: Water leaks from roofs, pipes, or foundation issues can directly wet the insulation.

- High Humidity: Prolonged high humidity in the surrounding environment can lead to moisture accumulation on surfaces.

Organic Debris Provides the Food: Even though Styrofoam isn’t organic, its surface can easily accumulate airborne organic particles like dust, dirt, pollen, skin flakes, or other microscopic debris. When these organic particles settle on a damp Styrofoam surface, they provide the necessary “food” for mold spores to germinate and grow.

Poor Ventilation: Inadequate airflow in areas with Styrofoam insulation can trap moisture and humidity, creating stagnant, damp conditions that are highly conducive to mold growth.

So, while Styrofoam is often described as “mold-resistant” because it doesn’t rot or provide inherent nutrients, it’s not “mold-proof.” If moisture and organic contaminants are present, mold can and will grow on its surface. Proper installation, effective moisture control, and good ventilation are crucial to prevent mold issues with Styrofoam insulation.

Conclusion

In conclusion, while Styrofoam itself doesn’t provide nutrients, black mold absolutely can grow on its surface when the right conditions—primarily moisture and organic dust—are present.

Understanding this is crucial for maintaining healthy environments, whether in your home, commercial spaces, or storage areas. Vigilance, proper ventilation, and prompt attention to water leaks are your best defenses against mold colonization on this ubiquitous material.

For those in industries requiring mold-resistant insulation and packaging solutions, sourcing materials from reliable suppliers is key. At Epsole, we offer wholesale Styrofoam products manufactured to stringent standards, providing excellent thermal insulation and structural integrity for your various needs. Contact us today to learn more about our dependable EPS foam solutions.