What Is Thermal Conductivity

Thermal conductivity is a fundamental property of materials, defining their ability to conduct heat.

In insulation materials, understanding thermal conductivity is paramount for optimizing energy efficiency and maintaining desired temperatures in various applications.

What Is Expanded Polystyrene (EPS)

Expanded Polystyrene (EPS) is a lightweight, versatile material known for its excellent thermal insulation properties. It consists of tiny, closed cells filled with air, which restrict the transfer of heat through the material. This unique structure makes EPS an ideal choice for insulation in construction, packaging, and various other industries.

Expanded Polystyrene Thermal Conductivity

Expanded Polystyrene (EPS) is a lightweight, rigid, and closed-cell insulation material commonly used in construction for its thermal insulation properties. Thermal conductivity is a measure of a material’s ability to conduct heat. In the case of EPS, its thermal conductivity refers to how well it can resist the flow of heat through it.

EPS thermal conductivity is low due to its structure. It is made up of tiny, interconnected foam cells filled with air. Air is a poor conductor of heat compared to solid materials like metal or concrete. Therefore, the air pockets within EPS act as barriers to heat transfer, reducing its thermal conductivity.

The thermal conductivity of EPS can vary depending on factors such as its density and the presence of additives. Generally, higher-density EPS tends to have slightly lower thermal conductivity because it contains more material and fewer air voids. Additives such as graphite can also be incorporated into EPS to further reduce its thermal conductivity.

Understanding the thermal conductivity of EPS is crucial in construction applications where efficient insulation is needed to maintain comfortable indoor temperatures and reduce energy costs. By minimizing heat transfer through walls, roofs, and floors, EPS helps buildings stay warmer in winter and cooler in summer, contributing to energy efficiency and comfort.

What Is Graphite EPS

Graphite EPS is an advanced variant of traditional EPS, enhanced with the addition of graphite particles. These graphite particles act as thermal reflectors, effectively reducing the material’s thermal conductivity.

As a result, Graphite EPS offers superior insulation performance compared to standard EPS, making it an attractive option for energy-efficient construction projects.

Graphite EPS Thermal Conductivity

Graphite Expanded Polystyrene (EPS) is a type of EPS insulation that incorporates graphite particles into the foam matrix. These graphite particles enhance the insulation properties of EPS by reducing its thermal conductivity.

Graphite is a highly efficient thermal conductor along its planes, but it has very low thermal conductivity perpendicular to these planes. When added to EPS, the graphite particles create a network within the foam structure, improving its ability to reflect and resist the flow of heat.

The presence of graphite in EPS reduces its overall thermal conductivity compared to traditional EPS insulation. This means that Graphite EPS can provide better insulation performance for the same thickness or the same level of insulation for a thinner material thickness compared to standard EPS.

Graphite EPS is often used in applications where maximizing thermal insulation performance is critical, such as in energy-efficient buildings or in areas with stringent insulation requirements. It offers an effective solution for improving energy efficiency and reducing heating and cooling costs.

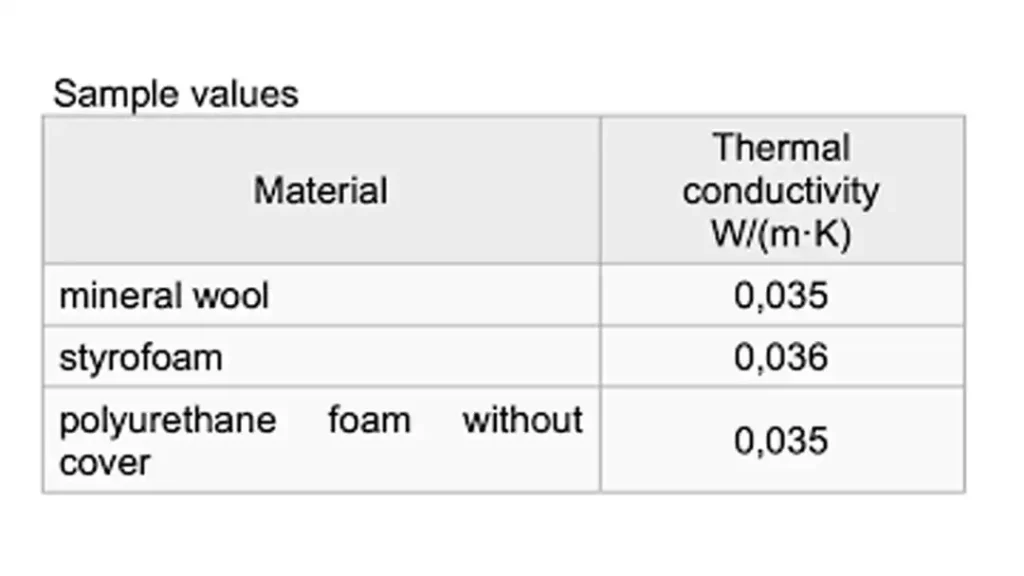

Styrofoam Thermal Conductivity

The thermal conductivity of Styrofoam, which is a brand of expanded polystyrene (EPS) foam, typically ranges from about 0.030 to 0.040 W/m·K (watts per meter per Kelvin). This means that Styrofoam is a relatively good insulator, as it has low thermal conductivity.

The low thermal conductivity of Styrofoam is attributed to its structure, which consists of small, closed-cell foam bubbles filled with air. Air is a poor conductor of heat, so the presence of these air pockets within the Styrofoam foam inhibits the transfer of heat through the material.

Styrofoam is commonly used in construction, packaging, and other applications where thermal insulation is necessary to prevent heat transfer. Its low thermal conductivity helps to maintain stable temperatures, conserve energy, and improve the efficiency of heating and cooling systems.

Factors Affecting Thermal Conductivity

Several factors influence the thermal conductivity of a material:

Material Composition: The chemical composition and structure of the material play a significant role. Materials with tightly packed atoms or molecules tend to have higher thermal conductivity because heat can travel more easily. Conversely, materials with a more open structure or filled with insulating components like air or gas tend to have lower thermal conductivity.

Temperature: Thermal conductivity often varies with temperature. In some materials, thermal conductivity increases with temperature due to increased atomic vibrations and collisions facilitating heat transfer. However, in others, such as insulating materials, thermal conductivity may decrease with temperature due to changes in molecular structure or increased presence of insulating components.

Density: In many materials, thermal conductivity tends to increase with density. Higher density typically means more closely packed atoms or molecules, allowing heat to transfer more efficiently through the material.

Moisture Content: Moisture can significantly affect thermal conductivity, especially in porous materials. Water molecules can conduct heat more effectively than air, so increased moisture content can lead to higher thermal conductivity. This is particularly relevant in building materials like wood or insulation materials like fiberglass.

Pressure: Pressure can alter the arrangement of atoms or molecules within a material, affecting its thermal conductivity. In some cases, increasing pressure can lead to a more compact structure with higher thermal conductivity, while in others, it can decrease thermal conductivity by reducing the mobility of particles.

Purity: Impurities or defects within a material can disrupt the regular atomic or molecular structure, hindering heat transfer and reducing thermal conductivity.

Orientation: In anisotropic materials, thermal conductivity may vary with direction. The arrangement of atoms or molecules may allow heat to transfer more easily in certain directions than in others.

Understanding these factors is crucial for selecting materials and designing systems with optimal thermal performance for specific applications, such as building insulation, electronic devices, or industrial processes.

Applications of EPS and Graphite EPS

The exceptional thermal insulation properties of EPS and Graphite EPS make them invaluable in various applications:

1. Building Insulation:

EPS and Graphite EPS are commonly used as insulation materials in residential, commercial, and industrial buildings. They help improve energy efficiency, reduce heating and cooling costs, and enhance occupant comfort.

2. Packaging:

EPS is widely utilized for packaging fragile items due to its lightweight nature and shock-absorbing properties. Graphite EPS further enhances thermal insulation, making it suitable for transporting temperature-sensitive goods.

3. Automotive Industry:

In the automotive sector, EPS and Graphite EPS find applications in vehicle insulation, reducing noise, vibration, and harshness (NVH), and improving overall comfort and fuel efficiency.

Conclusion

In summary, thermal conductivity is a critical parameter when evaluating insulation materials such as EPS and Graphite EPS. These versatile materials offer excellent thermal insulation properties, making them indispensable in various industries and applications.

Whether in construction, packaging, or automotive, EPS and Graphite EPS play a vital role in enhancing energy efficiency and maintaining optimal temperatures.

Please feel free to contact us at any time if you are looking for the premium eps products.